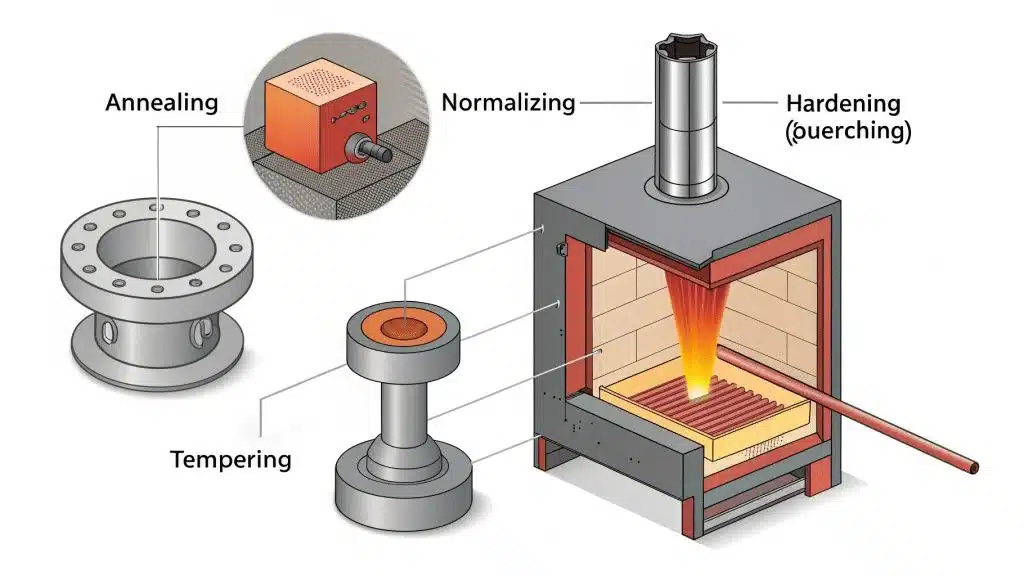

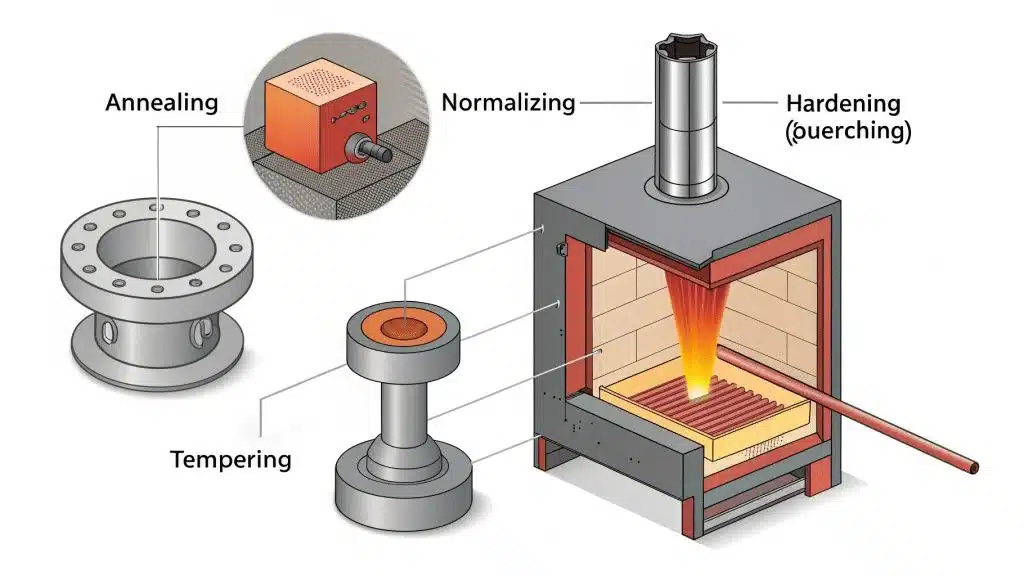

How Mold Steel and Heat Treatment Affect Precision Over Time

Mold precision is not fixed at the time of machining—it evolves throughout the mold’s service life. This article explains how

Mold precision is not fixed at the time of machining—it evolves throughout the mold’s service life. This article explains how

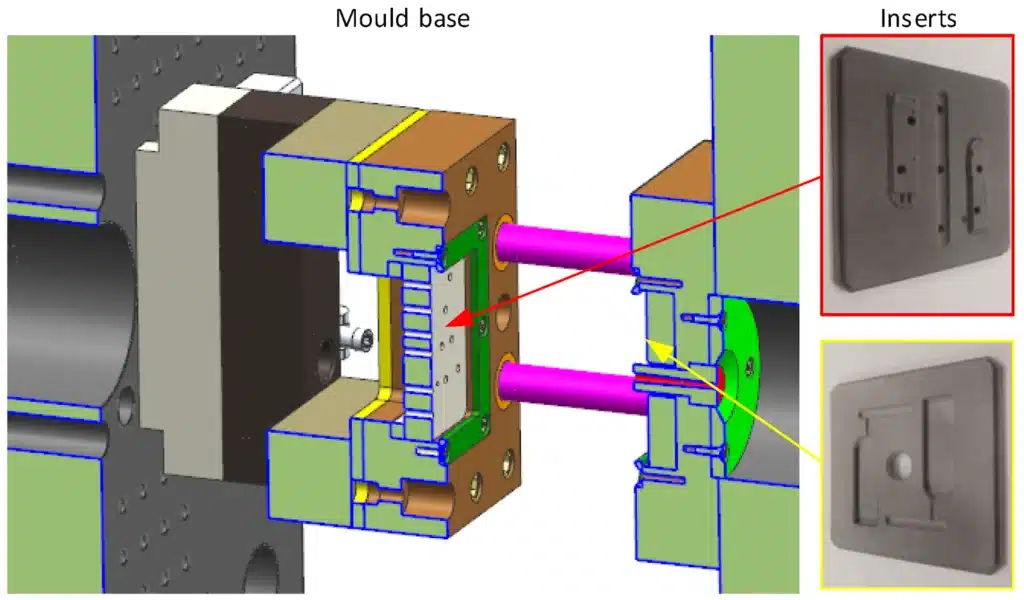

Precision mold performance depends heavily on assembly and fitting quality. This article explains how alignment, clearance control, and component interaction

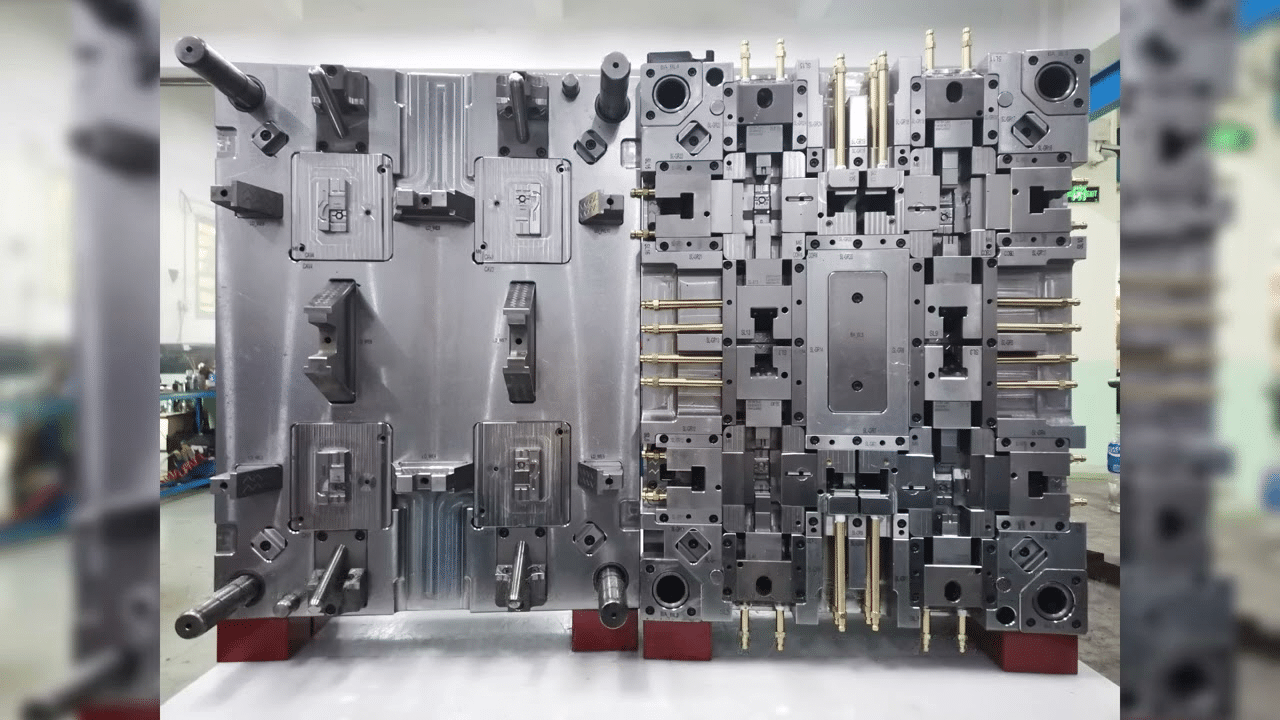

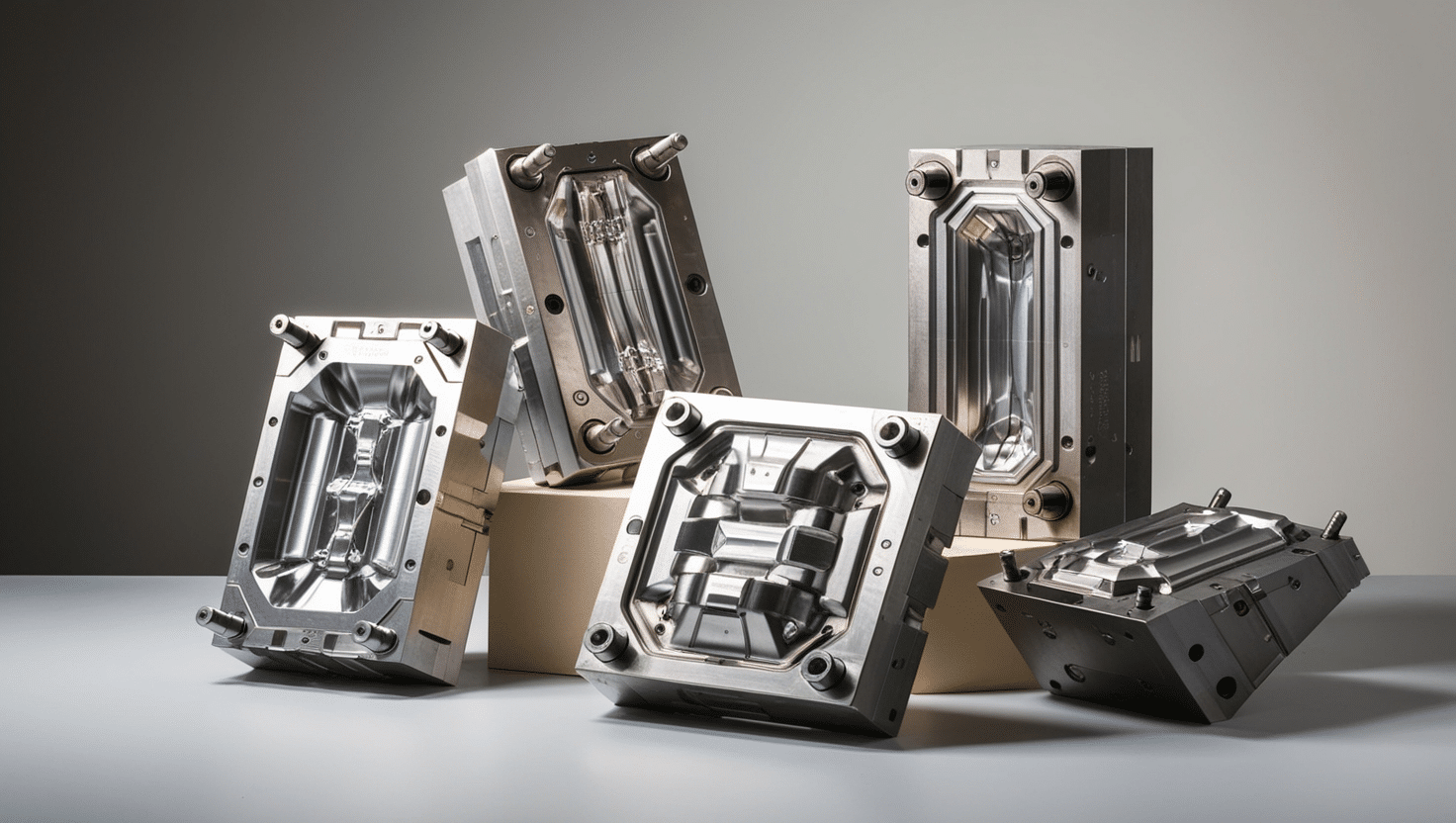

Precision mold manufacturing requires more than accurate machining. This article explains the complete precision mold manufacturing process—from design intent and

Tolerance planning in precision mold engineering goes beyond drawing accuracy. This article explains how functional requirements, wear behavior, and lifecycle

Injection molding stability depends less on machine tuning than on the quality of the mold itself. This article explains how

Precision molds often fail not because of machining limits, but due to design assumptions and manufacturing decisions made early in

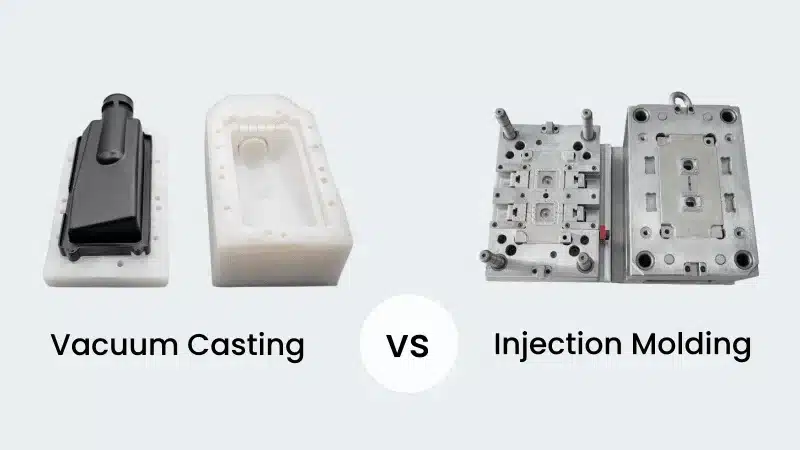

Precision molds and standard molds may look similar on drawings, but they behave very differently in production. This article explains

Precision molds in injection molding are often misunderstood as tools with extremely tight tolerances. This article explains what truly defines

Mold quality plays a decisive role in injection molding production outcomes. This article explains how tooling accuracy, material selection, and

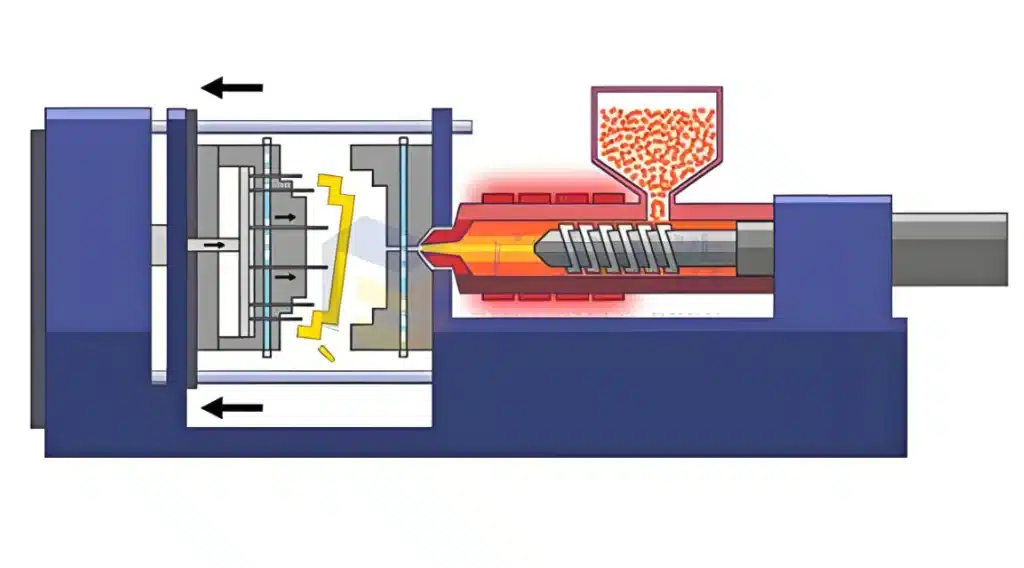

Injection molding is a multi-stage manufacturing process where tooling quality, material behavior, and process control determine production success. This article

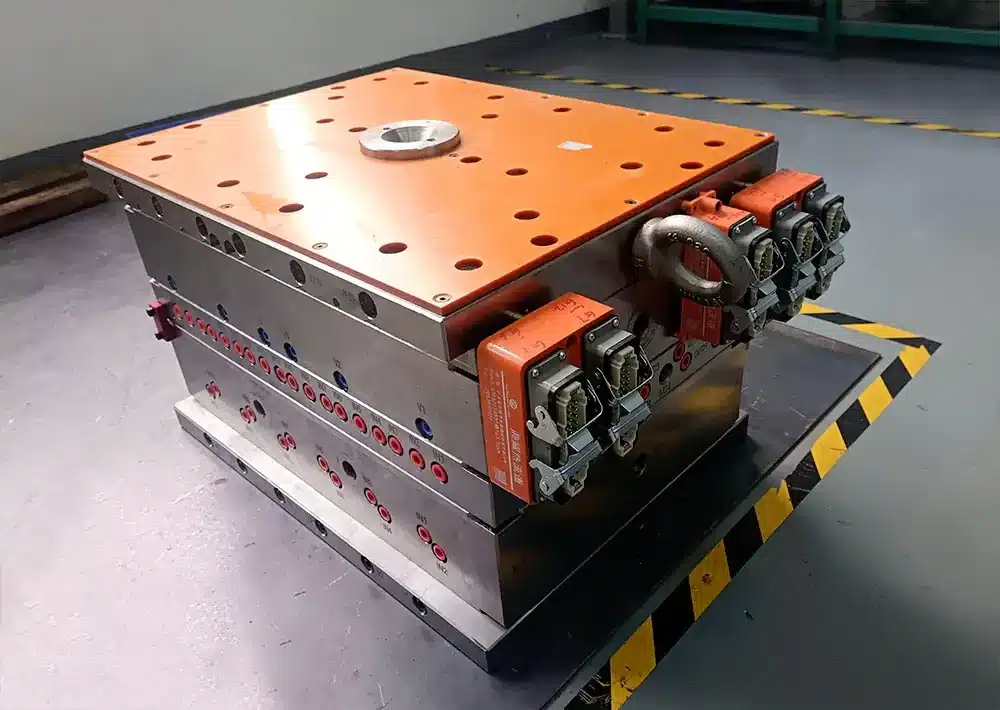

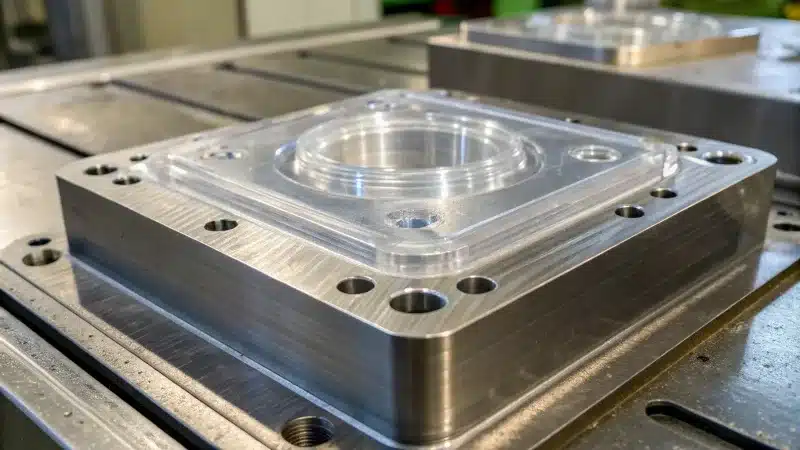

Ze Cheng Precision Mold Co., Ltd. uses modern Japanese equipment and rigorous quality control to produce high-precision mold parts and machine components to international standards, exporting worldwide.

WhatsApp us