CNC Testing: Complete Guide to Quality Control

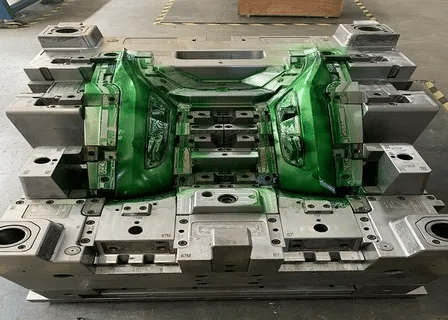

CNC testing and quality control is a broad process of checks and verifications that make machined parts fit the possibly strict specifications. The trend is back to one inspection each stage of correcting the error at the city of its origin, as it was done in the design review stage, perfecting the review stage at each step in tightness of the tolerance necessary in precision manufacturing. Important activities are first article inspection, in-process inspection, and final inspection with precision measuring tools. When key documentation and traceability systems are properly maintained, continuous improvement and customer confidence follows. With the changing manufacturing demands, it is important to have in place, strong quality controlling structures in terms of providing high-precision parts which are dependable and involve international standards as well as customer expectations.