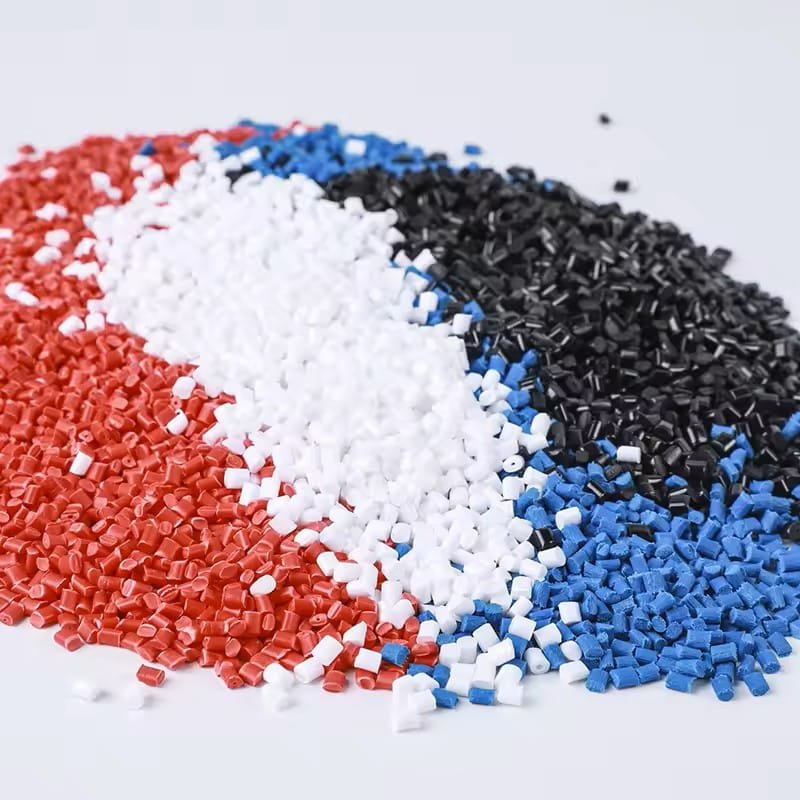

Polyvinyl chloride vs polypropylene

PVC and PP maintain distinct values as modern materials since they perform distinctive functions because of their separate characteristics. The properties of rigidity together with affordability make PVC suitable for buildings, automotive components, and industrial applications. The packaging sector together with healthcare and automotive industries rely on polypropylene because it provides effective chemical protection combined with operational flexibility and environmentally friendly characteristics. The combination of detailed knowledge about these two materials, including their temperature resistance, leads to safer products and better sustainable design solutions in application.