How Surface Finish in Mold Making Affects Final Parts

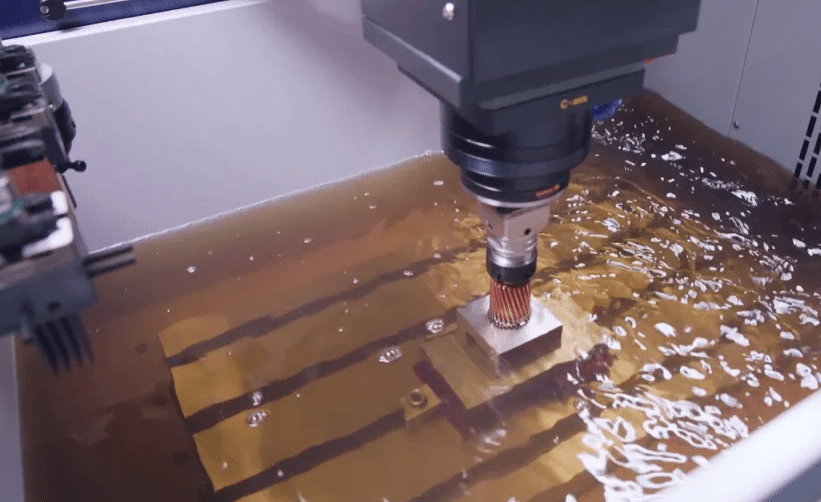

This article explains how surface finish in mold making affects final part appearance, functionality, and consistency, and how machining method, steel choice, and tolerance requirements influence achievable finishes. It covers why surface finish is a functional decision impacting production outcomes.