World of machining, especially in cnc milling, differs, and the choice of the correct milling technique has a direct impact on surface flair, tool life, and process efficiency. Two of the most popular strategies for milling will always yield a unique set of advantages and disadvantages – the climb milling and the conventional milling. Knowledge of the difference between climb milling vs conventional milling techniques, including the key advantages of each, is important for machinists who want to maximize performance and reduce wear or mistake in their operation. Such an investigation offers an advanced comparison between climb and traditional milling aspects of the way each of the processes affects the dynamics of machines, tool engagement, including tool deflection and behavior of material under stress.

Understanding Conventional Milling

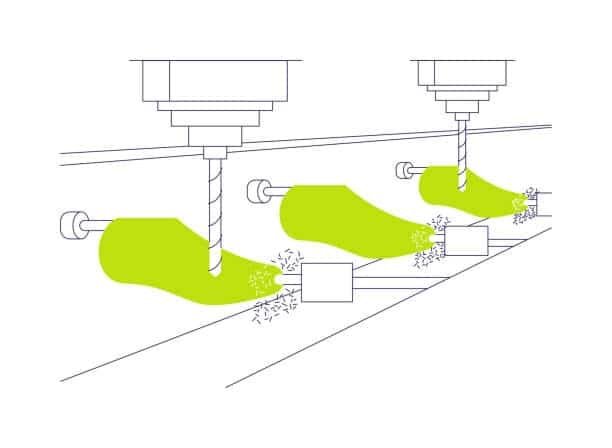

Conventional milling or generally known as Up-milling is the conventional cutting process in cnc milling where the cutter is positioned in the opposite direction against the feed direction. As the cutting tool’s teeth climb and come into contact with the material, the material responds by first the formation of the least chip thickness and where chip width starts up to the formation of the maximum chip thickness at the end of the cut, affecting chip formation . Such progressive contact makes the tool to rub with the surface before proper cutting starts, creating more heat and friction due to the cutting forces involved .

One of the main features of conventional milling is that it tends to push the workpiece away from the cutter. This requires a harder clamping mechanism and high strain over machine bearings and tool rigidity to account for cutter diameter, which is crucial to minimize tool deflection . to withstand cutting forces . However, conventional milling is still an option of choice under some applications especially when working with hardened scales on raw materials or when older machine backlash cannot be reliably counteracted. It provides better control in the engagement of initial materials such as cast iron and is more forgiving on interrupted cuts, which contributes to a better service life .

The Mechanics of Climb Milling

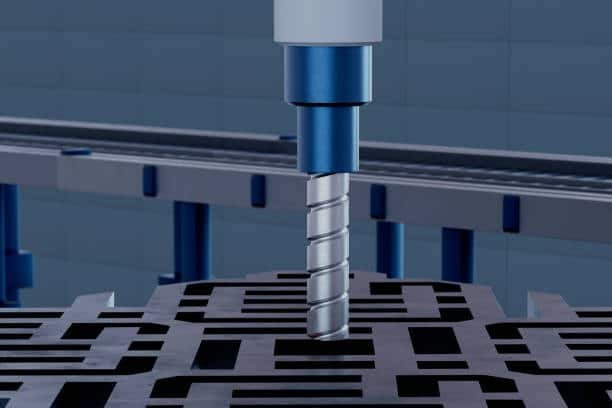

Climb milling, or “down milling,” is a more modern and effective method of service, where the cutter rotates in the same direction as the cutting process as both the feed and the position. This results in the maximum chip thickness and cutting half being brought to contact with the workpiece first., while also considering the cutter forces and the upward force applied , Consequently, there is a cleaner shearing action that contributes to a superior surface finish, especially where cuts occur, particularly with the cutting tool. Consequently, there is a cleaner shearing action that contributes to a superior surface finish, especially where cuts occur. with little friction and less heat production on the surface beneath the cutter .

This method applies a downward pressure, while the excess forces are carried upward and also incorporates upwards forces to the workpiece to stabilize it. with the help of the machine table and reduce chatter or pitch. As the edge climb cutting does not rub before cutting, leading to minimal generated heat, tool wear is greatly reduced and sometimes even on rough surfaces, the results are better., which helps in reducing overall heat generation . Climb milling however does necessitate a machine that is low on backlash as play in the feed screw can make the tool grab and pull, which has the potential of marring the part or tool. These, therefore, are the best types of CNC machines or equipment best suited to climb milling operations because of this reason.

Performance Differences in Surface Finish and Tool Longevity

Climb milling is typically superior to the conventional milling in performance vs conventional milling from a surface integrity perspective, as it produces a better surface finish, especially during the final pass . Its cutting action is inclined to have lesser burr formation and provides sleek, more polished finishes, contributing to a longer tool life . Since the chips are produced more efficiently and also evacuated in the direction of feed, especially when machining hard materials, there is less opportunity for recutting, reducing tool deflection effects which can still aggravate surface quality and which will also dull the tool.

The selected milling method also decreases the tool life severely. Enclosed milling, which involves the first contact and high cutting load , leads to increased heating at the point of the cutting edge causing the rapid tool to wear down. In comparison, climb milling, by cutting cleanly right from the start, will spread cutting forces across the work piece in a less abrasive way during the climb milling process. to have longer service intervals, reducing the heat generated in the proces . Nonetheless, an increase in the performance of climb milling needs to be matched with the requirement of machine stability, as any mechanical slack can lead to undesirable tool deflection and excessive vibrations. and is capable of destroying the outcomes.

Machine and Material Considerations

The material being milled generally plays a role in the decision between climb vs conventional milling. Harder or abrasive materials like hard materials such as cast iron that have the risk to tear or chatter could benefit from the traditional approach of controlled entry of conventional milling. Furthermore, with hard outer crust cutting castings or work piece in horizontal milling processes , conventional milling prevents chipping of tools from acute engagement while requiring less power .

On the other hand, in working with softer materials such as aluminum or plastic, or if high speed machining is required, then climb milling may be the better solution, as it provides a cleaner cut and in spending less time. That being said, the condition of the machine is paramount — older or manual machining machines with mechanical play may not be an appropriate option for climb milling due to climb milling backlash factors , as they might not handle the rough faster conditions effectively . may not be an appropriate option for climb milling because of possible backlash when the cutting tool’s teeth climb. , whereas the latest CNC platforms can fully benefit from the advantages of it.

Strategic Applications and Operator Preferences

Operator experience as well as strategic intent also determines the method. The conventional milling might provide a higher tactile feedback and expected behavior under roughing conditions when relatively fine precision is less important. Experienced machinists on the other side tend to prefer climb milling in finishing operations or when optimizing cycle times are a concern, as it is often preferred in the finish pass .

Some of the operations even combine two techniques in one pass and use the normal milling for rough cutting to handle the chip load and the rough surface produced by force exerted on the machine into climb milling in order to make the first pass and surface quality of the piece better. This is a hybrid approach that leverages strengths of both conventional and climb milling methods., sometimes known as spring pass. while negating on the weakness of two methods.

Conclusion

The decision to choose between climb and conventional milling is more than just a matter of taste; it is rather a pragmatic action that marks a recognition in machine dynamics, material properties, and goals. In mastering the strengths and weaknesses of each method, especially during the climb cutting finish pass with a rotating tool., machinists can elevate their craftsmanship, extend tool life, and improve the precision of the cutting edge work, particularly when dealing with thin floors. In the constantly changing world of manufacturing, this type of basic knowledge cannot be forfeited by someone who aspires to excel in the milling operation.

Furthermore, the advancements made on CNC technology have had the further effect of making the understanding of both milling techniques not only instrumental but also essential. How modern machines with modern control systems in cnc milling give machinists maximum advantage of climbs milling process without jeopardizing safety and accuracy. and insignificant backlash give machinists maximum advantage of climbs milling process without jeopardizing safety and accuracy. However, this does not make the conventional milling a thing of the past, it only highlights its application in specific situations, such as roughing passes or processes that involve older machines operating with up milling . A proficient machinist needs to be flexible and able to identify as well as employ the best option depending on the job being undertaken to ensure that productivity and quality are always at its best.