CNC machining or computer numerical control machining (cnc stands for computer numerical control) is a very complex cnc machining process of manufacturing that employs computer for controlling machine tools. It is the use of a computer program to dictate how and where cutting tools and machinery move to make an accurate automated output of parts. CNC machining is employed extensively in different industries for producing intricate and high precision components at a tremendous advantage in terms of velocity, precision, and flexibility.

One of the major advantages of CNC machining is its ability to manufacture cnc machined parts in tight tolerances as well as complex geometries, which cannot practically be done by manual machining. Computer-controlled machining processes eliminate human error while making it possible to repeat it and achieve high quality outputs even in the large production runs. Additionally, CNC machines can be used to work on various materials ranging from metals, plastics, and composites among others therefore making them very versatile across various industries, showcasing the benefits of computer aided manufacturing. (Aerospace, Automotive, Medical devices, and Electronics). Automation through CNC also cuts down on the time taken in production and the production costs as well as quick prototyping and ease of making adjustments to designs thus, making development of products faster.

This article examines the cnc definition machining, its working, application, various CNC machines, and its role in modern manufacturing, especially in relation to computer aided design cad., especially in relation to computer aided design cad . We will also cover the advantages and drawbacks of of CNC machining and wrap up with insights on its importance for the forward advancement of industrial production.

What is CNC Machining?

CNC Machining is the application of computers in the control of machinery e.g; mills, lathes, routers & Grinders. The key idea behind CNC machining is automation of the manufacturing process, stepping away from manual operations to make the process highly precise, and produce parts in high volumes at fast rates and more consistently. Where CNC machining is concerned, a machine is operated by computer program, usually in G-code. The machine tools are guided by this program in employing cuts, shapes and forms the workpiece to be the required parts in the final product. CNC machines are able to perform complex shapes and operations and rarely require a person to be involved.

This automation not only enhances precision but also significantly reduces the likelihood of errors caused by manual intervention, resulting in improved product quality and uniformity. CNC machining allows for the integration of multiple cnc machining operations—such as drilling, milling, turning, and grinding—within a single setup, streamlining production workflows and reducing downtime. Additionally, the flexibility of CNC programming and cnc processes means that designs can be easily modified or updated without the need for new tooling, making it ideal for both prototype development and mass production. As a result, CNC machining has become a cornerstone technology in modern manufacturing, driving innovation across numerous sectors by enabling faster turnaround times and cost-effective production of intricate, high-precision components.

How Does CNC Machining Work?

CNC machining is based on the principle that, computer directs the movement of machine tools along several axes. The process starts with making of the digital design or blueprint, usually one in the form of a 3D CAD (Computer-Aided Design) file. When the G-code is loaded into the computer in the machine, the cnc machining process begins and cnc machines operate and the machining process starts. The workpiece is tightly secured to the cnc machining equipment on machine’s worktable and the cutting tool is traversing in different directions in reference to the machines x, y & z axes and in accordance to programmed instruction cutting and shaping the material. Depending on the CNC machine in question, the cnc drilling process can be through drilling, milling, turning or grinding removal of material.

Types of CNC Machines

There are numerous varieties of the types of cnc machines and cnc tools, and these machines are designed to perform different types of operations. , and these machines are designed to perform different types of operations. Among the most popular cnc machinery are such as:

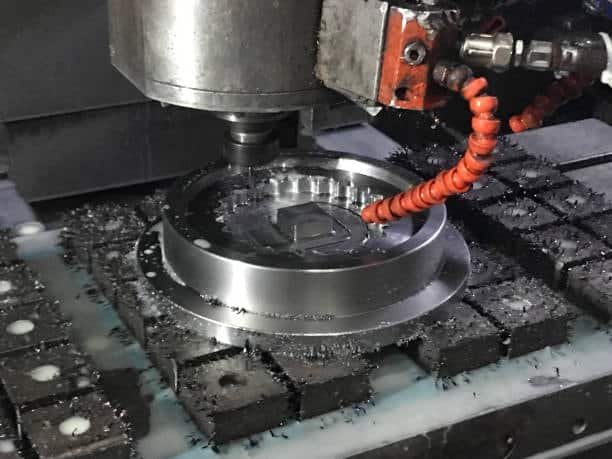

1. CNC Milling Machines

CNC milling machines are diversified machines that utilize rotating cutting tools to remove material off a given workpiece. Such machines are usually used for development of flat or complex surfaces, slots and holes. CNC mills are capable of machining in more than one axes, their versatility makes them suitable for a large battery of operations.

From basic 3-axis CNC milling systems to sophisticated multi-axis configurations, for example 5-axis mills, that permit highly intricate and accurately machined work with multiple orientations without part reorientation. This facility allows one to machine complex geometries and complex machinery with high surface finish and dimensional accuracy to excellent finish. In addition, CNC milling is compatible with a significant number of materials such as metals, plastics, and composites, making it very versatile in all industries. Not only the use of computer-controlled tool paths increases efficiency, but it also minimizes the waste because of optimized material removal thus contributing to money saving and environmentally friendly processes.

Applications of CNC Milling:

- Creating intricate shapes and designs.

- Manufacturing parts with high-precision dimensions.

- Used in the aerospace, automotive and the medical sectors.

2. CNC Lathes

CNC laths are machines which shape a workpiece by rotation with a stationary cutting tool which removes the material. Lathes are especially useful for the manufacture of cylindrical or conical forms, for instance shafts, spindles, valves.

CNC lathes provide accurate variable speed rotation of cutting tool and interchangeability thus parts of uniform diameters and smooth surfaces can be machined with intricate profiles. Unlike manual lathes, CNC lathes can automate computer aided machining processes and repetitive tasks with great accuracy hence efficiency and human errors are reduced. They can also be fitted with several tooling stations, allowing for several operations like threading, grooving, drill, taper turning to be conducted in one setup. Such flexibility makes CNC lathes and electric discharge machines indispensable tools in such industries as automobile, aerospace and hydraulic components manufacturing where there is a need of producing the high-quality cylindrical components.

Applications of CNC Lathes:

- Creation of cylindrical parts of high accuracy.

- Perfect for creating parts that are rotationally symmetrical.

- Acts frequently in industries that are high-volume produced entities, for example automotive manufacturing.

3. CNC Routers

CNC routers are like CNC mills, but they are usually used for the cut of softer materials such as wood, plastic and foam. Large-scale production through CNC routers has been used commonly in woodworking and sign-making trade.

CNC routers are very good at fast forming and laser cutting, engraving intricate designs onto softer materials with a high degree of accuracy and repeatability. Their capacity to work with large pieces of material and find delicate cuts makes them suitable for tasks like cabinetry, production of furniture, decorative panels, and custom signage. Unlike CNC mills routers work at higher spindle speeds while with lesser cutting forces thus sparing delicate application from causing harm. Besides, the CNC routers usually have an automated tool changer and a dust collection system that further adds to the efficiency and facilitates the cleaning of the working space. This combination of speed, flexibility, and accuracy has turned the CNC routers and cnc equipment into an essential equipment for artisanal crafts and the industrial manufacturing line, showcasing the advancements in cnc technology .

Applications of CNC Routers:

- Wood, plastics, and composite processing.

- Perfect for large parts including doors, panels and association signs.

4. CNC EDM (Electrical Discharge Machines)

CNC EDM machines refer to such utilization of sparks or electrical discharges to remove material from the workpiece. Such machining is widespread for the production of precise cavities or cavities in hard metals, namely tool steels, alloys.

CNC Electrical Discharge Machining (EDM) operates through the use of controlled electrical sparks between the electrode and workpiece, which reduces material in astonishing precision without the use of mechanical pressure. The efficiency of machining operation execution makes EDM very convenient for making complex shapes with sharp corners and fine details in hard to machine materials. There are two main categories of the process: sinker EDM and wire EDM whereby the shaped electrode and thin wire are used to create cavities and cut through the workpiece, respectively. Due to its capability of machining hard metals and complex geometries with close tolerances, CNC EDM and waterjet cutting is commonly used in tool and die making, aerospace, and medical devices industry.

Applications of CNC EDM:

- Producing intricate and detailed components.

- Ideal for hard-to-machine materials that cannot be machined with the standard tools.

- Extensively used in tool and die – making operations also used for preparation of molds.

5. CNC Grinding Machines

CNC grinding machines take material off the workpiece’s surface through the use of rotating abrasive wheels. These machines are employed to accomplish smooth fine finishes that part and are widely used in projects where accuracy in dimension and surface finish is critical.

CNC grinding machines are very important for delivering very fine tolerances and excellent surface when working on hard or tough materials that are hard to machine utilizing other methods. They can undertake a wide range of machining metal and grinding works from surface grinding, cylindrical grinding as well as centerless grinding due to their workpiece shape and requirements. The computer controlled movements provide for repeatable results, whereby CNC grinding is perfect for finishing tools, bearings, – engine components and other highly precise parts. In addition, programming intricate grinding paths also allows the manufacturers to increase efficiency while eliminating manual labor and thus increase quality and throughput of production.

Applications of CNC Grinding:

- Stuffles for reduced tolerances to be met and smooth finishes.

- Applied in aerospace, automotive industry, and medical equipment producing businesses.

Applications of CNC Machining

CNC machining is fundamental to contemporary manufacturing industry with a wide range of applications in other industries. Key sectors that are benefited from the cnc machinery and the associated machining processes include:

- Aerospace: CNC machining is employed to manufacture lightweight, strong components, e.g., turbine blades, landing gear components and structural elements.

- Automotive: CNC machines are involved in the production of precision engine parts, transmission parts and suspension systems.

- Medical Devices: CNC machining plays an important role in manufacturing different parts such as surgical instruments; prosthetics, and implants.

- Electronics: Many electronic components including circuit boards and connectors are produced using CNC machining.

Benefits of CNC Machining

Several impressive advantages provided by pre programmed computer software and computer aided manufacturing cam software through CNC machining and its machining processes, unlike conventional machining, make it an invaluable component of today’s manufacturing environment., unlike conventional machining, make it an invaluable component of today’s manufacturing environment:

1. High Precision and Accuracy

CNC machines deliver great exactness creating parts with close tolerance and complex geometries. Such an accuracy level, due to numerical control, is imperative for such industries, which demand precise specifications, aerospace and medical devices manufacturing among others. The accuracy that can be achieved of CNC machines and their cnc operations is not only something which means parts will fit and operate perfectly in assemblies but something that makes less post-processing or rework necessary. Such a level of accuracy is essential in industries such as aerospace and medical devices, as slight variations could impact safety, performance, and adherence to the regulations. In addition to that, CNC technology ensures that manufacturers are able to repeat complex designs in mass production without losing the level of quality and reliability. The CNC machining has therefore become a hallmark in the production of high performance component to the stringent standards as required by such highly developed fields.

2. Automation and Efficiency

Using CNC machining, production process is mechanized to a large extent, eliminating the necessity of human hands. This enhances production rates that minimize chances of human error making it perfect for high-volume manufacturing environment. Not only is the production cycles covered by the high level of automation in CNC machining accelerated but the final part quality is kept consistent from one set of orders to another. After initial programming and set-up, the CNC machines can be run with little or no watching hence manufacturers would be able to run this machines round-the-clock even during un-scheduled shifts. This operation that is constantly running greatly enhances the output while reducing labor costs drastically. In addition, when there is a reduction of manual intervention the risk relating to variability, misalignment, and also dimensional errors is greatly reduced. Such benefits prove CNC machining especially useful for high-volume industries, such as the automotive industry, the electronics industry, or the manufacturing of industrial equipment, where efficacy and the scope of accuracy are both essential.

3. Flexibility and Versatility

CNC machines can handle a vast number of materials, such as metals, plastics and composites, reflecting the versatility of types of cnc available in modern manufacturing . Adapted to a wide array of functions such as drilling, milling, turning, and grinding, they are also reusable. This is one of the reasons why CNC machines are very useful for a wide range of manufacturing from prototyping to full-scale production. Their capacity to simply shift between different materials and operations with negligible changes enables efficient manufacture of all from the lightweight plastic products to the heavy-duty metal components, thanks to advanced cnc systems . Furthermore, CNC machines can be reprogrammed for utilization in different tasks hence making it an easy task for manufacturers to adjust quickly to any changes in design or changes in demand to produce. This flexibility does not only save operational costs but also increases overall flexibility, thus, making CNC machining important technology in contemporary agile manufacturing, alongside additive manufacturing processes .

4. Consistency and Repeatability

A program once created, especially when considering various cnc programs, can be replicated by CNC machines to produce the same part over and over again with little deviation so that consistent quality of parts in every batch produced is maintained. This repeatability is one of the main strengths of CNC machining and cnc drilling , and especially, industries were uniformity is a must, meaning automotive, electronics, and aerospace manufacturing. After the initial programming and setup is confirmed, CNC machines bear the capacity to produce identical parts continuously with little variation irrespective of the volume of an item being produced. This means that all components are made to the identical specifications, often utilizing servo motors, thereby reducing wastage, increasing reliance and through easing of quality control. Moreover, the digital storage of CNC programs enable easy recall and reuse, so it is easy to pick the production back up at any time without worrying about consistency and precision.

Challenges of CNC Machining

Though CNC machining is quite reliable, there are certain challenges accompanying the process.

- High Initial Setup Costs: CNC machines can be quite costly to acquire and to install, particularly for the small or medium-sized business.

- Complexity of Programming: Writing G-code and programming a CNC machine may take a lot of skillful operators and engineers.

- Material Limitations: Some materials including high-strength alloys will need some sort of special tooling or processes for machining.

Conclusion

While CNC machining has changed the course of the manufacturing industry through unmatched level of precision, efficiency and versatility. Whether it is the development of complex parts for the aeronautical industry or the manufacturing of top quality parts for auto industry, CNC Machining, driven by numerical control, remains an integral part of contemporary industrial production. Using CNC machining as its capability to automate processes, minimize errors and yield repeatable results, the cnc machining process offers significant advantages that complement the future of manufacturing. Furthermore, the combination of CNC machining with modern technology like the CAD/CAM software, robotics, and IoT systems also benefits its potential. These developments codify smarter and more interconnected manufacture spaces where machines can interact, evolve, and optimize on real-time. As industries continue to place increasing premium on higher levels of customization, shorter lead times and better quality products, the CNC machining technology emerges as the cornerstone technology that can deal with this challenge effectively. Its capability in fostering innovation, cost reduction, and productivity improvement implies that it is essential in formulating the next generation of manufacturing.