CNC machined parts and precision mold parts are often confused as they often both focus on similar production methods such as milling or turning, but are hardly interchangeable as the confusion can result in a mismatch in expectation and production failure. Typically, CNC machined parts are either standalone or assembly components in products, although the internal parts of an injection tooling are mold components, whose precision directly determines the quality of molded parts over thousands of injection cycles. Most OEMs believe that any supplier of CNC machining will consistently produce mold parts that can be trusted, and this is normally a cause of tooling and production problems such as misalignment or premature wear. CNC machined and precision mold components might have similar manufacturing processes, however, they used different functional purposes and risk profiles. The main distinction between CNC machined parts and mold parts is in terms of functional usage, tolerance purpose, and subsequent implication. Being a senior tooling consultant who has been giving OEMs sourcing strategy recommendations over 15 years, I have observed how this confusion has led to expensive changes- it is better to explain at the beginning to integrate smoothly and ensure reduced risks. This paper breaks down the basics in order to allow mechanical engineers, mold designers and purchasing managers to be confident in conquering these differences.

Why CNC Machined Parts and Mold Components Are Often Confused

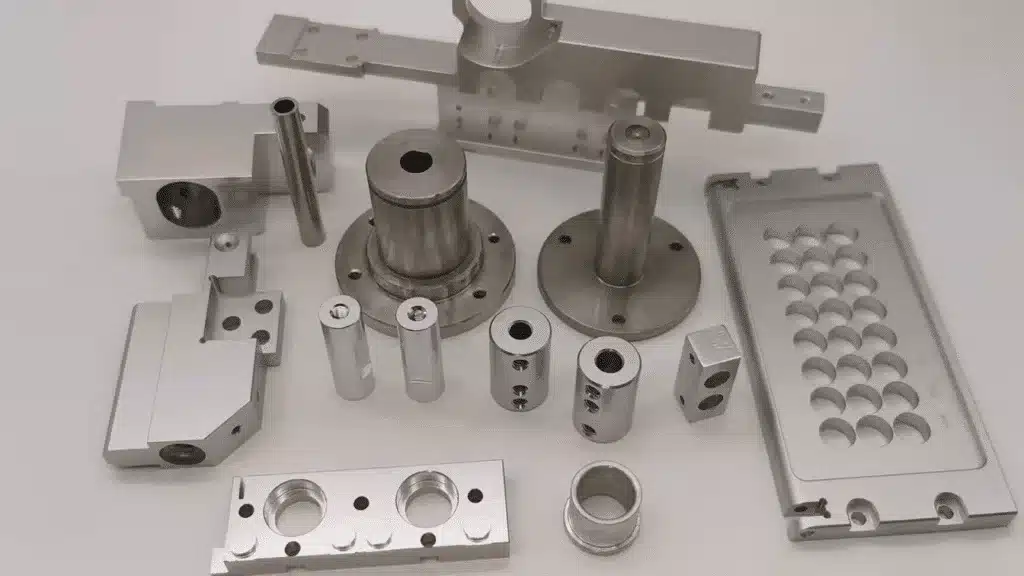

The mix up of CNC machined parts and mold components is usually due to the fact that they are manufactured in a similar manner yet not taking into consideration their application which is their end-use context resulting in major sourcing mistakes that alter the timeline of projects. The two common uses of CNC machining are contour shaping (milling) or symmetry shaping (turning) but that is as far as the two are similar, CNC machined parts may be part of a finished product as brackets or housings, but mold components such as cores or ejector pins operate under high pressure and high temperature in the tooling process. Language confuses this, where precision CNC parts is a wide term that the suppliers can decipher at will, though not implying the specialised understanding required of the mould elements that have to hold sub-0.01 mm tolerances of greater than 500,000 cycles.

This overlapping, in my case when going through the OEM blueprints, deceives the buyers to have general machinists deployed as toolists, and the final delivery of components that fit but not functional- components that warp under heat (i.e. inserts). Early identification of these differences will avoid premature allocation of resources and will also make suppliers fit the application requirements.

Manufacturing Purpose — End-Use Parts vs Tooling-Critical Components

CNC machined components essentially differ between end-use or assembly components (such as those manufactured by CNC machining) and components in a mold (which are tooling-sensitive elements making high-volume production possible). CNC machined components, such as custom gears or fixtures, are meant to be integrated into products where the component has a high-end-use or low-cycle failure, i.e. the failure of a single component does not spread to the rest of the product. Mold components, however, such as cavities or sliders, are responsible for mold geometry, and have to cope with the recurring stresses in order to produce reliable parts, and the accuracy of this components affect directly on yield rates and minimization of faults within injection runs.

This difference is important in that tooling parts need a wear and thermal stability foresight, unlike individual parts. The reliable suppliers manage both but specialize as required when it comes to evaluating scope custom parts manufacturing exposes the role of integrated capabilities in facilitating this equilibrium without excessive generalists.

CNC Machining as a Method vs Mold Components as an Application

CNC machining can be used as an ultra-flexible approach to the shaping of metals, whereas the production of mold components requires particular application knowledge beyond the simple programming and execution.As a method, CNC is effective at creating geometries by means of controlled tool paths which can be applied to either a prototype or a bracket. Nonetheless, application molding presents domain-specific issues: steels that are heat-treated should be optimized, pin concentricity needs to be improved so that they do not bind, or undercuts in inserts must be handled to allow easy ejection.

Shapes can be offered at the general CNC shops, yet to ensure tooling-based considerations, like stress relief to preclude post-assembly distortion, tooling specialists are involved. It is the gap in this expertise that causes the immediate backfiring of an assumption of method proficiency- the special methods, as I have elaborated on in CNC machining for precision mold components, ensure application-aligned results.

Tolerance Intent and Functional Requirements

There is a significant difference in tolerance intent between CNC machined parts and mold components where the former is concerned with dimensional requirements in assembly, whereas the latter is concerned with functional fits, which survive in operation under loading requirements. On non-critical parts, e.g. CNC parts, a tolerance of ± 0.05 mm can be applied but on parts of the mold, e.g. matching surfaces, tighter limits are required, e.g. ± 0.005 mm to prevent leakage of resin or misplaced parts that multiply defects with repetition. Strictness is not necessarily a virtue; over-specification raises cost without benefit when important functional specifications such as concentricity of bushings to guide without damaging them are concerned.

This is guided by trustful manufacturers who instruct on where tighter tolerances can be held performance.. Knowing the tolerances of precision mold component tolerances assists OEMs to know when specs are in accord with actual needs.

Risk, Responsibility, and Downstream Impact

Risk pertaining to the profiles shows a sharp divergence: a defective CNC machined part may stop one assembly, whereas a defective mold element may cause failure of the whole production line resulting in downtime and scrap. Isolation is a common response to CNC parts failures, replace and continue but mold problems spread defects through thousands of moulded parts, raising liability on the part of the supplier.The influence of molds increases the downstream effect: the inaccurate fittings result in disproportional cooling, resulting in warped or unproductive holes.

This is something that OEMs have to consider in the sourcing process since generalists can deal with contained risks, but tooling requires experts. The connection to injection molding quality can be used to explain how the stability of components leads to greater results.

Common OEM Mistakes When Treating CNC Parts as Mold Components

One of the most common OEM errors is to believe that CNC capability directly transpires to mold expertise, and disregards the specialized validation required in tooling settings. Another: neglecting domain-specific testing, such as thermal cycling models, resulting in components which work well alone, but fail in a list. This is made worse by focusing on price, rather than functional risk, where cheaper CNC parts may save a lot in the short run but pay premiums by neo-tooling the moulds.

These mistakes are caused by the underestimation of the requirements made by an app; they may be prevented by its proactive evaluation.

How OEMs Should Decide Between CNC Part Suppliers and Mold Component Manufacturers

Repeatability of the process and domain expertise should be used by OEM to make decisions: in the case of stand-alone CNC components, any general supplier with good machining is good as long as the tolerances are moderate. However, when it comes to mold components, it is better to count on specialty manufacturers that may demonstrate tooling-specific experience, e.g. propose wear-resistance finishes or fit-enhancers.. In a case of the overlap of needs, consider trials- begin with low-risk components to check consistency.

This reasoning will guarantee the sourcing to be consistent with functional requirements and not to spend excessively on unwanted specialization.

Conclusion — Understanding the Difference Prevents Costly Mistakes

To conclude, OEMs that want to have a consistent manufacturing process, stable tooling behavior, and a successful manufacturing process in the long-run, it is necessary to make a distinction between CNC machined parts and mold components. This makes sourcing a strategic asset but not a gamble by aiming at functional roles, tolerance intent and risk profiles. Definite distinction enhances improved decisions, thus reducing interference and maximization of performance in accurate applications.