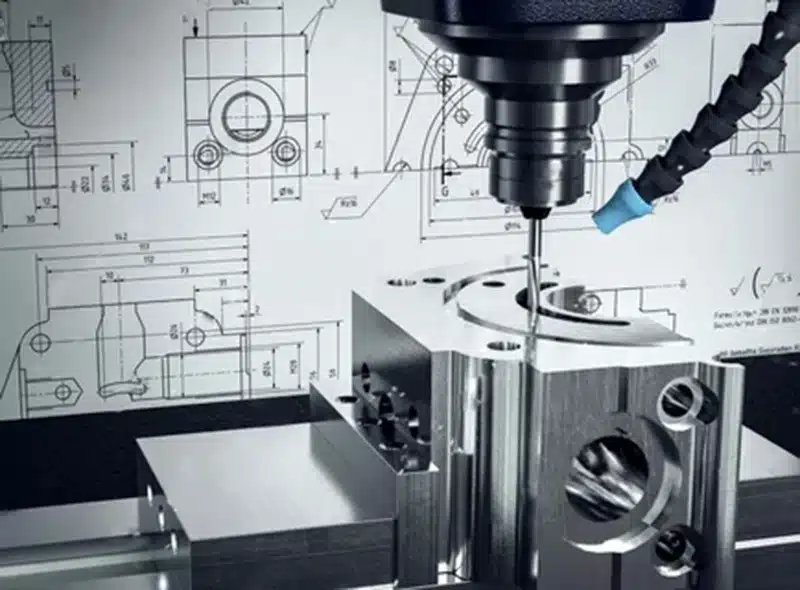

CNC machining is central to the manufacturing of precision mold components because it offers repeatable geometry control, stable dimensional accuracy, and flexibility across complex part designs. However, CNC machining alone does not automatically guarantee high precision. Many buyers assume that using CNC equipment inherently defines accuracy, when in reality, precision is determined by how machining processes, tolerance requirements, and material behavior are managed together.

CNC machining is fundamental to precision mold components, but achievable accuracy depends on process selection, tolerance definition, and material behavior—not machining alone.

This distinction is critical for mold designers, OEM engineers, and sourcing teams who must balance performance, cost, and long-term tooling stability rather than relying on equipment labels or generalized capability claims.

Why CNC Machining Is the Primary Method for Precision Mold Components

CNC machining dominates precision mold component manufacturing because it offers controllable, repeatable, and scalable accuracy across complex geometries.

Injection molds rely on tight positional relationships between components such as inserts, cores, pins, and guiding elements. CNC machining allows these relationships to be produced consistently through digital control, multi-axis movement, and stable fixturing strategies that conventional manual machining cannot reliably achieve.

Compared with traditional machining, CNC machining provides:

- Higher repeatability across batches

- Better control of complex geometries and profiles

- Faster iteration from design changes

- Consistent integration with inspection and measurement systems

That said, CNC machining should be viewed as part of a broader manufacturing capability rather than a standalone solution. Effective Custom Parts Manufacturing depends on how CNC processes are integrated with engineering review, tolerance analysis, inspection control, and material selection—especially for mold components that directly affect tooling performance.

Key CNC Machining Processes Used for Mold Components

Different CNC machining processes are applied to mold components based on geometry, function, and precision sensitivity, not convenience.

CNC Milling

CNC milling is widely used for mold inserts, cavity blocks, and structural components requiring complex surfaces or multi-face machining. Precision here affects:

- Cavity geometry accuracy

- Shut-off alignment

- Feature-to-feature positioning

Limitations arise when deep pockets, thin walls, or long tool reach introduce vibration or thermal distortion.

CNC Turning

CNC turning is commonly used for cylindrical mold components such as core pins, ejector pins, sleeves, and bushings. Accuracy matters most for:

- Diameter consistency

- Concentricity

- Surface integrity affecting wear and movement

However, ultra-long or slender parts can experience deflection, requiring realistic tolerance expectations.

CNC Drilling

Drilling operations support ejector systems, cooling channels, and fastener interfaces. Precision drilling affects:

- Hole alignment

- Flow balance in cooling systems

- Assembly repeatability

Deep-hole drilling introduces additional challenges related to straightness and tool stability.

Secondary Operations (High-Level Reference)

Processes such as grinding or EDM are often used when CNC machining alone cannot meet surface finish or geometric requirements. These are complementary, not replacements, for CNC machining.

Tolerance Requirements and Machining Reality

Tolerance requirements must reflect what CNC machining can realistically achieve, not what drawings ideally specify.

For precision mold components, typical tolerances often range from:

- ±0.01 mm for general functional features

- ±0.005 mm for alignment-critical interfaces

- Tighter ranges only where function clearly demands it

A key distinction exists between design tolerance and achievable machining tolerance. CNC machining accuracy is influenced by machine condition, tooling strategy, thermal control, and inspection method. Over-specifying tolerances increases machining time, inspection cost, and rejection risk without improving mold performance.

Understanding the limits of tight tolerance precision machining helps engineers align expectations with manufacturability and avoid unnecessary cost escalation.

Material Selection and Its Impact on CNC Machining Accuracy

Material behavior determines whether CNC-machined accuracy can be maintained over time.

Different mold component materials respond differently to machining stress, heat treatment, and operational loads. Tool steels, stainless steels, and hard alloys vary in:

- Machinability

- Thermal expansion

- Distortion after heat treatment

- Wear resistance during molding cycles

Even perfectly machined components can lose dimensional stability if material selection is mismatched with application demands. A clear understanding of mold component materials is essential for achieving not just initial precision, but long-term dimensional consistency throughout mold life.

CNC Machining Limitations in Precision Mold Components

CNC machining has physical and economic limits that cannot be ignored.

While CNC machining offers excellent dimensional control, limitations arise from:

- Tool deflection and vibration

- Thermal expansion during long machining cycles

- Trade-offs between surface finish and dimensional accuracy

In some cases, achieving extreme surface finishes or tight geometric tolerances requires secondary processes. CNC machining enables precision, but it does not eliminate the need for engineering judgment.

How CNC Machining Quality Affects Injection Molding Performance

Machined accuracy directly influences molding consistency, not just part dimensions.

Precision CNC machining affects:

- Component fit and alignment

- Shut-off integrity

- Wear behavior over repeated cycles

Poor machining quality can lead to inconsistent part ejection, flash formation, or uneven wear, all of which degrade injection molding quality over time. Stable machining results contribute to predictable mold behavior and reduced downtime.

Common Misunderstandings About CNC Machining for Mold Components

Several misconceptions distort how CNC machining is evaluated in mold manufacturing.

Common misunderstandings include:

- CNC machining always achieves micron-level accuracy

- CNC machining eliminates the need for inspection

- Material choice does not affect tolerance stability

In reality, CNC machining performance is inseparable from process control, inspection strategy, and material behavior.

How OEMs Should Evaluate CNC Machining Capabilities Rationally

Rational evaluation begins with functional requirements, not capability claims.

OEMs should focus on:

- Matching tolerance requirements to component function

- Understanding process capability, not advertised accuracy

- Evaluating long-term performance rather than initial cost

Precision CNC machining should be assessed as part of a complete manufacturing system that includes engineering review, inspection discipline, and material expertise.

Conclusion — CNC Machining Is a Tool, Not a Guarantee

CNC machining enables precision mold components, but it does not define precision on its own. Accuracy emerges from the interaction between machining processes, tolerance strategy, and material behavior.

CNC machining should be evaluated as part of a complete precision manufacturing system—not as a standalone promise of accuracy. When applied rationally, it becomes a powerful tool for stable, repeatable, and cost-effective mold component production.