CNC screw machining, including swiss screw machining, reflects an intricate way of shaping highly-precise threaded parts that are commonly known as screws. The prevalence of CNC machining technique in manufacturing is largely due to the CNC precision together with the screw thread complexity. Screw making is essential in aerospace, automotive, medical and electronics as the skeletal basis of CNC machining, assuring the development of highly performing threaded elements applicable to multiple fields.

What is Swiss Screw Machining?

CNC screw machining refers to a process where the CNC equipment is used to create precision screws, bolts, as well as a lot of other threaded fasteners. Unlike manual processes that were practiced initially CNC screw machining enables the auto-ization of all the steps therefore giving rise to higher accuracy, precision, and efficiency.

Key Processes in Swiss Screw Machines

CNC screw machining begins with several important stages that together ensure manufacturing of detailed and high quality screw parts, maintaining tight tolerances . These processes include:

1. Turning

While CNC screw machining is initiated, turning is the critical first move. The lathe holds raw material securely and the cutting tool is rotating to remove material from work piece.

2. Thread Cutting

After turning lies the essential process of thread cutting in CNC screw machining. A custom-made tool is used by the machine to cut threads onto the cylindrical material to shape the unique helical design that characterizes screw.

3. Drilling and Boring

There are times when drilling or boring takes place during CNC screw machining in order to form required openings.

4. Milling and Grinding

CNC screw machining has milling and grinding processes incorporated to have the design features such as slots, grooves, or chamfers.

Materials Used in CNC Swiss Screw Machine

CNC screw machining provides flexibility as it can accept many materials. The substance used depends on a particular application requirement and the properties needed in the finished screw.

1. Stainless Steel

Of the most frequently used materials in CNC screw machines, a popular one is stainless steel precision components, because of its strength, anti-corrosive qualities, and impressive longevity.

2. Aluminum

Due to its weight advantages and the resistance against corrosion cutting tools, aluminum is a popular material in usage where lighter parts are required.

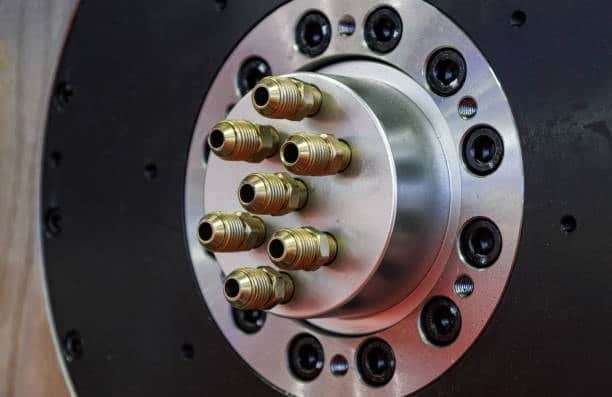

3. Brass

Brass becomes a material, which gained the world’s attentions in CNC screw craft, due to its machinability, rust quali? , and elegant looks cam machines.

4. Titanium

Its superior strength with low weight makes it perfect for high performance industries, such as aerospace and medical fields.

Advantages of CNC Screw Machining

CNC screw machining outperforms conventional manual processing machining operation in a number of absolutely fundamental ways.

1. High Precision

CNC screw machining processes guarantees outstanding quality and accuracy, consistent screws reliable machine that have very little tolerances and good threads.

2. Complex Thread Forms

CNC technology permits manufacturing individual thread forms extreme precision through swiss machining allowing the use of CNC in applications where exquisite profiles are a must consistent quality.

3. Efficiency and Speed

CNC screw machining runs with unparalleled precision pointing towards high volumes precision parts rapid production of large volumes of screws with minimal human intervention.

4. Reduced Material Waste

CNC screw manufacturing reduces the volume of material removed by controlling material waste by way of careful machining.

Applications of CNC Screw Machining

Such a practice of screw machining is applied in many areas where there is a need for high accuracy in fasteners. Key applications include:

1. Aerospace Industry

CNC screw machining plays a significant role in manufacturing screws and fasteners, which are critical parts of aerospace systems such as aircraft and spacecraft.

2. Automotive Industry

CNC screw machining also continues to be critical in creating screws and fasteners that are required to build engines, transmissions and assemble car bodies.

3. Medical Devices

CNC screw machining industry is applied in the medical field in order to produce screws and fasteners for implants, surgical tools and prosthetic devices.

4. Consumer Electronics

The manufacturing of small precise screw for use in smartphones, laptops and televisions relies on CNC screw in consumer electronics.

Conclusion

CNC screw machining, a sophisticated production method focusing on precision machining , is essential in offering high levels of accuracy and flexibility in screw, bolt, and threaded part production. Marginality of CNC screw machining, the capability of producing complex threads, and the opportunity for high-quality parts on a global scale make it indispensable for industries such as aerospace, automotive, medical and consumer electronics.