In injection molding, such quality problems as warpage or sink marks are run-to-run, but they are not the natural consequences of injection molding, and they are caused by gaps in tool design, material handling, or control of parameters that good manufacturers mitigate with proactive preventive measures. Although some variation is inherent because of the dynamics of material flow, the vast majority of defects are system-wide, and these defects can be traced back to design and setup choices and can be avoided with responsible engineering. Most customers would believe that the quality problems in injection molding are due to operator error, whereas most of the problems are in tooling, choice of material, and process configuration. The quality problems of most injection molding are not accidental, but can be predicted results of the tooling choice, process regulation, and material behavior. High quality injection molding is obtained by making sure that it is prevented, not by checking it after the production. Being a manufacturing quality engineer who has years of experience troubleshooting the molding lines of automotive and electronics OEMs, I have observed how the emphasis on root causes upstream transforms chronic issues into a rare exception.

Why Injection Molding Quality Issues Are Often Misunderstood

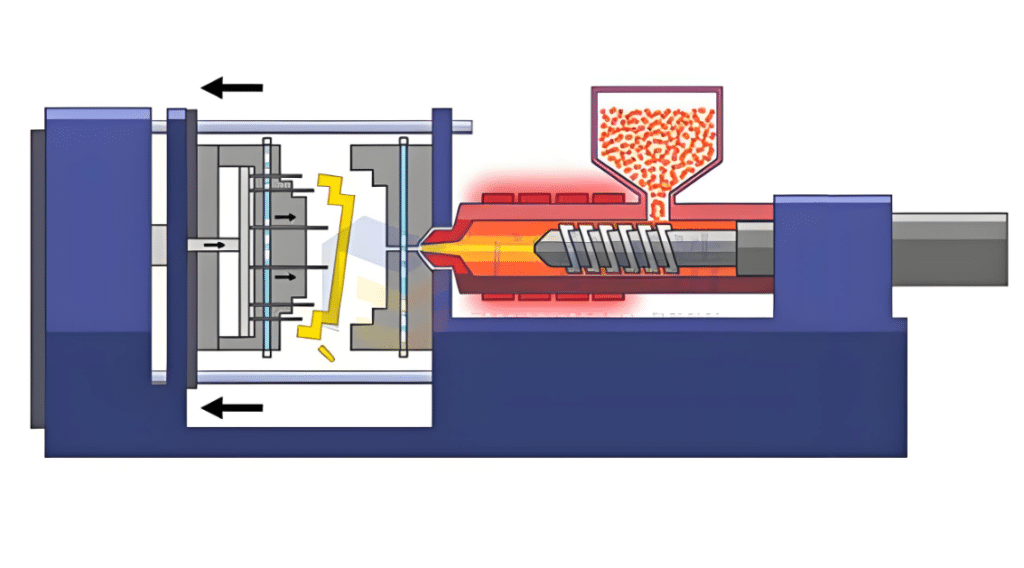

The quality problems linked to injection molding are often misinterpreted as the surface flaws such as flash or voids are seen as the isolated cases when they are in fact the systemic problems within the chain of manufacturing. These symptoms at the surface versus root causes may be vital: a short shot may look like an incomplete fill, but it may be because the melt temperature was inconsistent or the venting was not effective in the mold, and not an isolated glitch. It is a mistake to concentrate on machines or operators alone, modern presses are predictable but unless there is a balanced tooling and controlled parameters variability permeates in either material lots or environmental influences such as the humidity level of the resin flow.

It is imperative to know the entire system of manufacturing: starting with the drying of the raw pellets to the ejection, every process is interconnected, and all the areas of weakness are amplified by others. The holistic perspective has been visible in the facility audits that I have been conducting whereby defects recur in the facility because of the management of where the final product only addresses the results of the product rather than providing an opportunity to prevent a failed product.

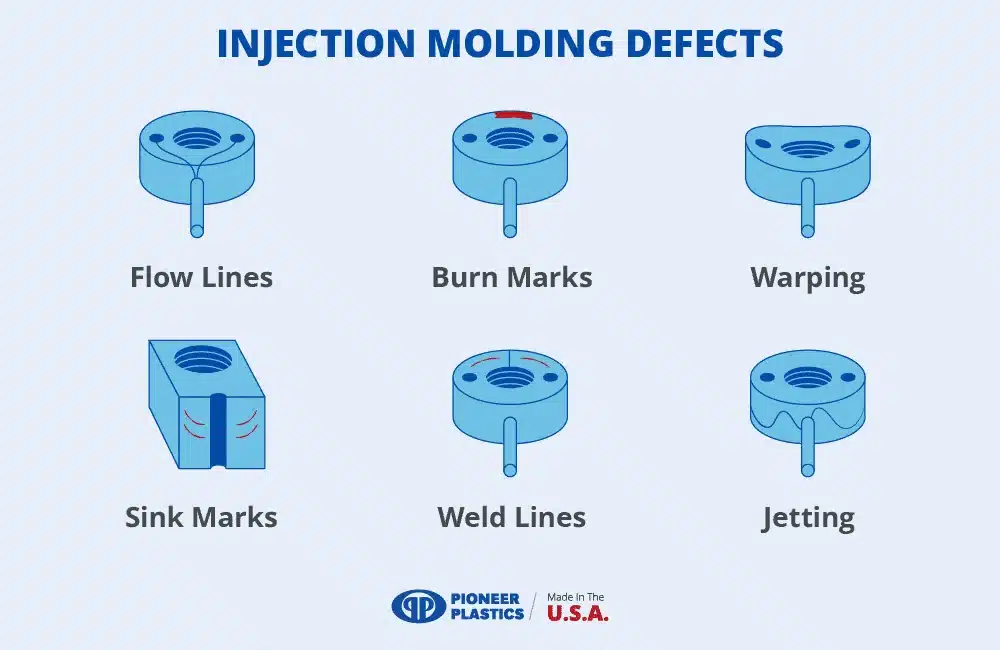

The Most Common Quality Issues in Injection Molding

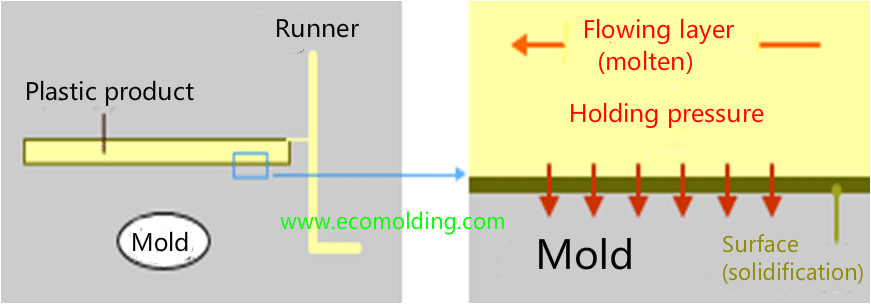

The least frequent but most prevalent problem of injection molding can be caused by an unequal distribution of the material flow, cooling or pressure, yet any of them can be traced to the particular causes, which can be controlled by the manufacturer through the design and monitoring. As one example, warpage can happen when there is an uneven cooling process, resulting in uneven contraction, usually because of different wall thicknesses or poorly defined cooling routes to allow hotter parts to shrink more than the others, producing bowed components. The sink marks are formed as depressures over areas where the thicker material solidifies at a slower rate, drawing the surface material inward, usually as a result of inadequate gating to form hot spots or the lack of pressure to pack the material, and the loss of volume.

Short shots occur when the molten plastic does not fill up the cavity due to low temperatures of the melt, thick viscosity resin, or plugged vents that entrap air and impede flow. Flash occurs as excess material along parting lines, which is due to over-pressurization, abrasion of the edges of the mold, or misalignment to permit resin escape. Dimensional inconsistency is due to cycle to cycle changes in temperature or pressure, whereby parts do not run to specs. All of these can be traced to avoidable aspects, such as flaws in the design of mold or parameter drift, and not a matter of chance.

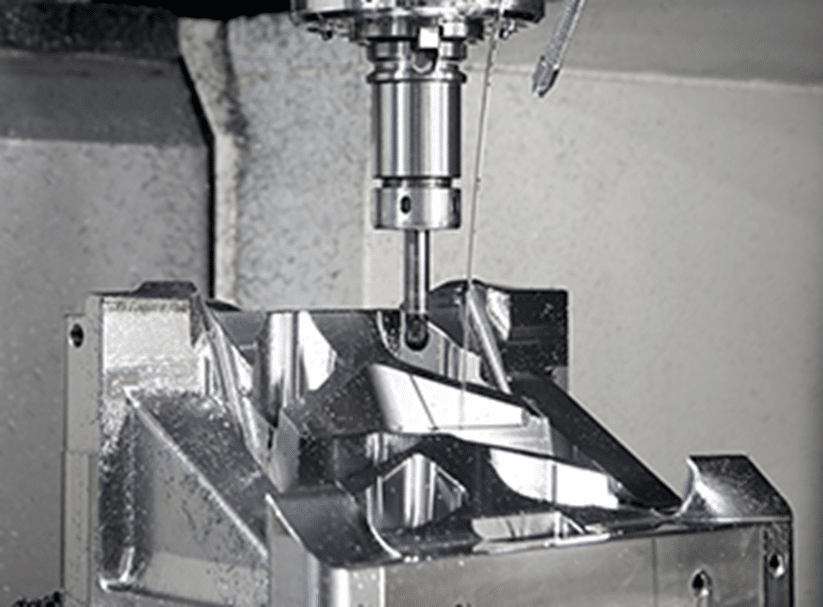

How Tooling Quality Influences Injection Molding Defects

The quality of the tooling also has a direct bearing on defects in injection molding since the design and the construction of the mold dictate the limits to the flow of the material, uniformity of cooling and distribution of pressure- any defects at this point are passed onto all the parts produced. Correct cavity balance will result in equal fill in multi-cavities, avoiding a short fill in some and creating flash in others, poor balance will result in pressure imbalance that increases sink marks or warpage. Ventilation is very important in air release-lack of sufficient vents leads to gas trapping, forming cavities or burns whereas excess ventilation can lead to flash.

Much is made of the cooling design: the channels spaced too far away come in contact with thick parts, causing differential shrinkage and dimensional variation. In projects that I have been able to work on, conformal cooling upgrading minimized warpage by 40 percent in multifaceted shapes. When evaluating precision injection molding services, tooling precision is non-negotiable—it dictates defect frequency more than any other factor.

Process Control as the Primary Method of Defect Prevention

The main technique used in prevention of defects in injection molding is process control since the parameters do not change too much between one run and another, the material can be maintained at the same state and the occurrence of problems such as short shots or flash is minimized. Changes in temperature of the melt, even by 5-10 o C, change viscosity, and therefore fill rates and packing, leading to sink marks or variable fill levels unless maintained constant. Repetitive cycles are based on variables measured: Clamp force, injection rate and hold time should be consistent with the profile of the resin to prevent excessive or insufficient packing.

Controlled variation is also applicable to environment such as consistent drying of resin to avoid splay caused by moisture. In line optimizations that I have managed, sensor feedback loops reduced defects by stabilizing them, enabled stabilized sensor feedback loops to control better than fixes that are reactive. To ground the knowledge, it is worth investigating the injection molding process reveals how this discipline turns potential issues into reliable outputs.

Tolerances and Dimensional Stability in Injection Molding

Tolerances and dimensional stability during injection molding are confused because nominal specs should consider the material shrinkage and thermal effects to prevent the inconsistency in occurrence across a run. The allowable range is determined by nominal tolerance such as ±0.1 mm on a feature but functional tolerance looks at the performance of the part, such as warpage due to uneven cooling can cause it to fall out of spec even though it was initially accurate. All plastics shrink (0.5-2 percent) based on the thickness and direction of flow, and this must be compensated in the design of the mold, to ensure stability.

This is worsened by thermal behavior: as fast cooling fixes stresses into place, post-ejection distortion occurs. Planning tolerances alleviate them by increasing the non-critical ranges, trading of cost versus reliability.. Details in tolerances in injection molded plastic parts guide this, ensuring stability without over-specification.

Quality Control Systems That Prevent Recurring Issues

The problem-solving method of injection molding is quality control systems; defects do not spread because at each level, not only incoming materials are checked, but also final verification is done. Outbound material control- moisture or contaminant checking of resin stops splay or brittle as unexamined lots bring variance. Parameters such as cavity pressure are monitored by in-process inspection which catches drifts that lead to short shots before they hit batches.

Last minute inspection ensures dimensions and appearances, yet the core of such prevention is feedback control: tooling or parameters are improved by a reject. This reduces the number of repetitive cuts in the system that I have used by connecting the production data with the mold maintenance. Adapting from quality control in precision mold components extends this rigor to molding.

Why Experienced Manufacturers Focus on Prevention, Not Rework

Skilled manufacturers value preventing injection molding errors more than repairing them because fixing them at the early stage is much cheaper than fixing them at the final stage rework may add two times the unit cost of the part by scrap and downtime. Stable processes such as validated gating remove the cause of flash or a void and reduce the risk in the long term keeping yields at 95 or above. Such a preventative approach instills confidence in OEM: through continuous production, there are fewer surprises during assembly or operation, leading to trust in large-volume production.

I have been managing the lines of medical devices and, in terms of long-term efficiency, I have observed the prevention reducing expenses by 25 percent.

Conclusion — Injection Molding Quality Is Engineered, Not Inspected

Conclusively, the quality of injection molding is not a problem addressed after the defects are discovered but a disciplined engineering decision that was made much before the inspection of parts. Focusing on tooling accuracy, process consistency, and systemic controls, manufacturers provide credible results that reduce risks and maximize productivity. The quality of injection molding is produced by prevention, which is the reason why it is very consistent a feat that cannot be attained by inspection alone, it forms the basis of reliable production.