Problems with quality in precision mold parts are standard in the fabrication but hardly inevitable the majority of such problems are attributable to adjustable elements such as variation in the processes or lack of suitable verification, and proficient shops will resolve them using disciplined methods. Although some variation is natural in machining complicated geometries, avoidable failures frequently indicate more profound lapses in control, e.g. disparities in heat treatment or unobserved tolerances. Lots of buyers consider quality problems as the inevitable risks, but not the signs of inadequate process regulation. The majority of the quality problems with precision mold components are not unintentional ones, but they indicate flaws in processes control and the engineering judgment. Unified quality in precision components of molding is based on avoidance rather than detection. Being a quality engineer and having spent years in analyzing the failures in tooling at shop floors and OEM audits, I have been able to observe how preventive steps can turn possible failure points into non occurrences. This paper presents typical issues and the ways to avoid them to help OEM mechanical engineers, mold designers, and quality managers to evaluate the rigor of suppliers.

Why Quality Issues Occur in Precision Mold Components

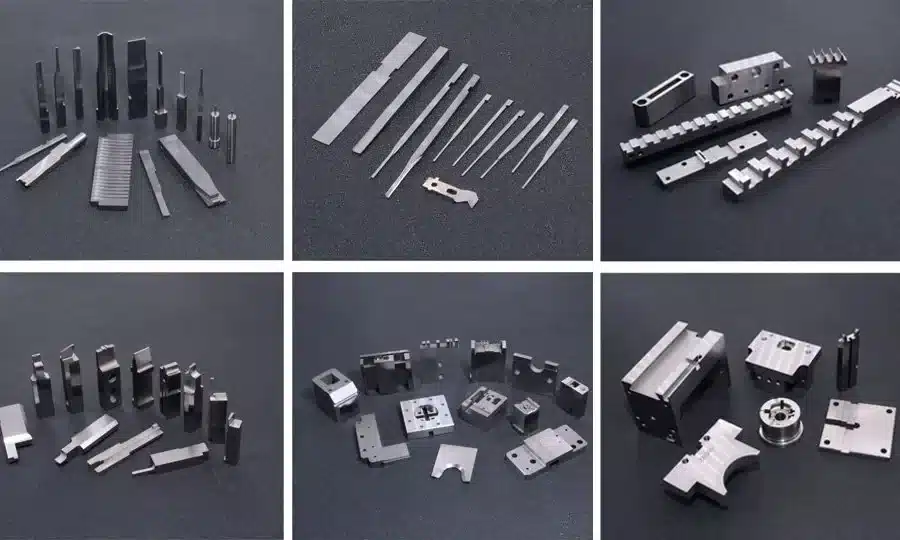

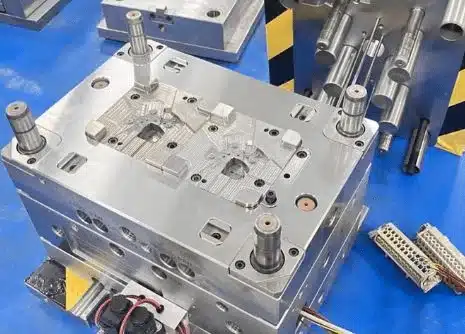

Inaccuracy of the components of precision moulding, most of the time, is due to the nature and depth of their functions where minor failures in control may result in ripple effect failures in their operation. These elements, cores, pins, sliders, have to undergo accurate interactions over high pressure and temperature variations thus even slight variation in geometry or material characteristics interferes with alignment and flow. This is exacerbated by tight fit requirements, a 0.01 mm discrepancy between ejector bushings is binding and a small number of deviations added up, such as stacked tolerances in multi-part assemblies, leads to gaps between parting lines that permit flash to escape.

It has its foundations in system causes: unstable machining parameters create variability and untaken thermal effects during treatment distort features. These are not accidental in my assessments of medical tooling rejects, which are related to other elements, such as tool wear or coolant variation, and why it is necessary to take a comprehensive view of these situations instead of making fixes.

Manufacturing Stability as the First Line of Quality Control

Stability Manufacturing stability serves as the ultimate protection against quality problems in precision mold components, where unstable processes create repeat defects that progressively reduce repeatability between batches. Variations to machine calibration or material lots can change the dimensions by 0.005 mm and the fit may initially work but fail during cycling. The repeatability and defect rates have a direct correlation: processes that have CpK less than 1.33 tend to produce up to 10-20% non-conformance since the variation builds up into assemblies.

This can only be stabilized by controlled environments, e.g. by checking the spindle speeds, tested fixturing, and by observing drifts to prevent late. This reduces defects through facility improvements I have managed by targeting the sources of variance. In robust custom parts manufacturing, stability integrates calibration protocols and data tracking to minimize repeat issues, ensuring outputs remain predictable without constant rework.

Dimensional and Fit Issues Caused by Tolerance Mismanagement

Tolerance mismanagement causes the occurrence of dimensional and fit problems in precision mold components when the misalignments due to size or shape cause poor functioning of the mold. Deviations of sizes: oversized pins or undersized holes, which are a result of uncalibrated tools or oversights in thermal expansion, introduce interference fits, which bind together during ejection. This is further worsened by poor fit or misalignment such that even 0.002 mm offsets in core-cavity pairs cause uneven pressure leading to part warpage or incomplete fills.

These are compounded by stack-up effects: multi-component configurations such as sliders and guides increase small errors into operational failures. Prevention is dependent on capability measures- mapping process limits to specifications. To have real benchmarks, look at precision mold component tolerances aids in setting achievable ranges that avoid mismanagement.

Surface, Alignment, and Functional Interaction Problems

Precision mold components can be subject to surface, alignment and functional interaction issues whereby an uneven contact can begin to cause localized wear or instability during assembly and use. Lumpyness due to lack of uniform grinding of surfaces forms high spots and loads are concentrated on them in a way that causes galling to sliders with the friction spiking too soon. Local wear initiation is followed: Micro-pits or scratches trap abrasives and increase erosion in high motion parts such as ejector mechanisms.

The instability of the assembly can be caused by such misalignments as the deformed plates or as the holes that are off-centered and do not mate each other easily, thus making the vibration and spreading the cracks. These are not cosmetic, they interfere with functionality, such as hampering cool down in channels. When it comes to trouble shooting electronics molds, I have been able to trace back the molds upstream to the lapses such as poor stress relief, and I have focused on avoiding the problem by profiling the surfaces and performing alignment tests.

Quality Control Systems That Prevent Defects

In the production of precision mold components, quality control systems eliminate defects by incorporating verification at multiple layers through the detection of problems prior to their accumulation, and emphasize process data instead of end checks. In-process checking- post roughing gauging- This process identifies drifts during the initial stages and prevents scraping of batches without changes. Verification is more than checking: it incorporates statistical analysis to verify capability, such as a check on hardness uniformity after treatment.

Closing the gap by feedback and corrective action: non-conformances are the basis of root-cause probes, which update protocols to avoid such occurrences in future. With proper systems, the number of defects in audits that I have participated in has decreased by half in this cycle. Exploring quality control in precision mold components reveals how these integrate for proactive defect avoidance.

How Quality Issues Impact Injection Molding Performance

Malfunctions in the quality of precision mold parts are direct threats to injection molding performance since small failures such as surface pit can grow to large failures like resin accumulation or uneven demolding. A misplaced slider may begin with a friction degree but then bind increasing cycle times and flash as the pressure variations. This increases variation: the effect of distorted inserts is dimensional drift in parts, a drop in yield, 98 to 85 percent per run.

It is a systemic relationship, poor fits cause disruption in cooling, leading to warping or voids. This by means of strict component QC stabilizes outputs as connected in. injection molding quality, preventing small issues from halting production.

Common Misconceptions About Mold Component Quality

Another common myth is that quality is ensured by final inspection only disregarding the fact that any process that has variances that go unnoticed during the inspection conceals defects that will manifest themselves at the later stage. Another: deviations that are not significant, but even a 0.005 mm deviation may translate into assembly cavities that permit leakage. Lastly, thought of quality issues as fixable at the assembly stage assumes that internal defects, such as internal stresses, cannot be fixed and cause failures in the field.

Such omissions are based on the perception of quality as a response; proactive prevention requires an upstream approach.

How Manufacturers Systematically Prevent Quality Issues

One way that manufacturers avoid quality problems in precision mold parts is by standardizing the process, whereby the documented machine and treatment parameters reduce variation among the operators and operational shifts. Capability validation-conduction of trials to verify CpK on feature of interest- check before full running to identify mismatch early. Continuous improvement involves feedback: after-delivery information optimizes heat-treat cycles or tooling configurations, and the frequency (recurrence) is minimized by 30-40% in well-developed systems.

This reasoning is based on process mappings that I have undertaken and focuses on control as opposed to correction in achieving long-term reliability.

Conclusion — Quality Is Designed and Controlled, Not Inspected In

In conclusion, to avoid any quality problems in precision mold parts, one has to know the place of origin of problems and manage them before parts have left the machine. Manufacturers provide components with no surprises by giving stability of the process, verifying, and providing feedback. Quality is not inspected in it is built and managed this is the regulated strategy that converts the possibility of failures to regular accomplishments.