In the cutting-edge communication space of product development where performance, safety and costs effectiveness merge, the The computer aided engineering task has become an all-important facet of innovation alongside cae tools and the computer aided design software. No longer just a post-design validation tool, CAE now becomes an active participant across the board in the engineering cycle – from concept modeling to ultimate optimization. Through the emulation of real-life circumstances in a virtual space, CAE will help engineers to anticipate issues, enhance performance, and take data-based decisions without touching a single prototype.

Understanding the Core of Computer-Aided Engineering

Computer-Aided Engineering are Computer-Aided Engineering are methods that use all computer aided engineering software for the purpose of engineering work. especially that of simulation, analysis, and even the optimization work. CAE extends beyond mere design; It goes into the functioning behavior of a product, its product quality, and its physical behavior under real-world constraints. From measuring thermal conductivity to moving water around, CAE allows engineers to experiment with different variables on a computer prior to making any investment in physical fabrication.

FEA, CFD, and MBD are the pillars of CAE, which include various cae tools . Complex geometries are deconstructed into disjoint elements or regions with the help of these tools, where highly detailed analysis of each segment’s reaction to external stimuli can be done. Unlike traditional testing, which is time-consuming and expensive, CAE comes with the form of rapid feedback from cae software companies , which can effectively speed up the cycles of design iterations.

The Integration of CAE in the Product Development Workflow

Normally, Normally, the design process in engineering design involved a linear approach.: design first, test later. CAE has disrupted this sequence by integrating analysis right into the act of the engineering process and manufacturing processes. Today, engineers are able to simulate piles of scenarios before any prototype is even manufactured, and so they are able to rid off flaws early on and optimise designs on the spot.

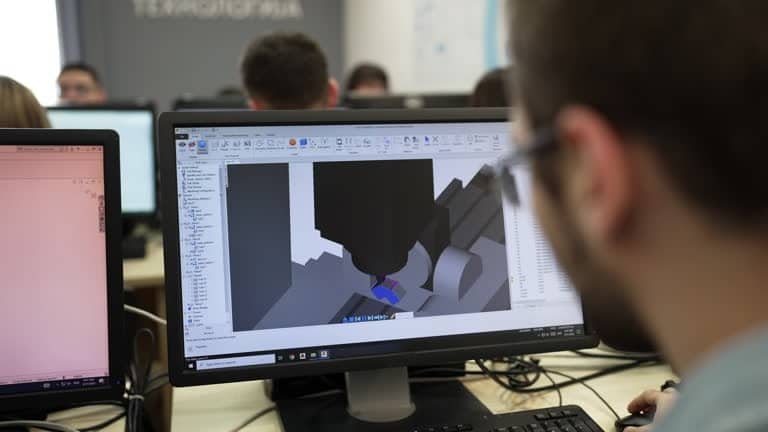

By linking CAE with the Computer-Aided Design (CAD) platforms, engineers can constantly test and optimize models in one and the same environment without the need for building physical prototypes . When geometry or material content changes, it ripple effects instantly into the simulation results for a dynamic feedback loop. This end-to-end ecosystem This end-to-end ecosystem promotes a more agile, collaborative, and efficient workflow in the overall product development process. that is particularly important to product design ecosystems where margins are low and compliance is highly complex.

Industries Benefiting from CAE Technologies

CAE’s range extends practically through every industry for which performance and accuracy count. In the automotive industry for example, engineers use CAE, including computational fluid dynamics cfd, In the automotive industry for example, engineers use finite element analysis fea, including computational fluid dynamics cfd, for crash impacts simulation, thermal management of engines., and to resolve engineering problems regarding aerodynamics properties. It allows for safer, lighter, and more fuel-efficient cars without the expense of multiple physical tests, thereby lowering product development costs .

In aerospace, CAE is applied to examine product performance, In aerospace, CAE is applied to examine product performance, applied loads stress analysis forces on fuselages., wings’ flexibility, and heat transfer of jet engines. The stakes for a flight or success are undeniably high – only high performance computing CAE, including computational fluid dynamics, can handle that kind of precision during pre-production consistently. In the same way, simulations of fluid flow through a stent or movement of the joint in a prosthetic can contribute to a more effective and reliable product in medical device engineering.

CAE plays a significant role even in different areas like civil engineering by utilizing various manufacturing tools and analysis tools. and renewable energy, particularly in enhancing product performance . It allows for seismic simulations or wind analysis on turbine blades, which leads to significant process improvements for afety and efficiency of energy.

Advantages That Define CAE’s Value

With such wide benefits derived from CAE, one of the most attractive benefits of CAE is its ability to reduce prototyping exercises. It reduces physical prototyping situations, and this is valuable since CAE provides an actual representation of how the physical form of the model will look when applied in real life compared to other CAD methods (Kenney and Bikle 58). Production and testing of several prototypes are not only costly but also time-consuming. By eliminating physical trials and using dependable digital simulations in its place, CAE reduces this cycle through post processing .

Also, CAE offers a platform for design optimisation. Instead of adopting a single concept of product design, engineers can draw from a vast tableau of choices, that they test in different circumstances to determine the one Such processing, including multibody dynamics and simulation tools, results in increased performance, the amount of materials saved, and long-term cost reductions.. Such processing, including multibody dynamics, results in increased performance, the amount of materials saved, and long-term cost reductions.

CA cannot only predict the outcomes of risks but CA cannot only predict the outcomes of risks but can also demonstrate compliance with regulations through finite element analysis.. Through this, companies are allowed to show the safety and functioning of their products prior to participating in certification procedures, as they are done virtually but according to the international standards, which requires significant computing power . It not only de-risks the investment but also hastens market penetration.

Challenges in Implementing CAE Effectively

CAE implementation is not all rainbows and butterflies, however, as it has its own set of challenges. The software is usually very intensive in terms of computer power, especially while simulating complex assembly and nonlinear behaviors. This requires investment in high performance cloud computing and sophisticated computer aided engineering software hardware of cloud-based applications that come with the ability to process large datasets.

Furthermore, the outputs of the CAE projections are highly reliant on users’ expertise. An incorrect mesh density as well as incorrect pre processing, analysis of boundary conditions or oversimplified material properties result in misleading results. Therefore, CAE can only be used as a powerful tool in the hands of trained professionals from cae software companies who know not only the physical principles but the boundaries of such a simulation.

Finally, although CAE can shed deep insights, it does not completely eliminate the need for physical validation. Feed into simulation models only includes data and assumptions. It is only as correct as they are.

Conclusion

Computer-Aided engineering is not a distinctive advantage in the modern age of the digital – it is the minimal feature required. It allows engineers to stop guesswork and enter a predictive, data-driven design space. With industry becoming more complex, and the deadline more pressing, CAE is the backbone of the entire engineering process and a very pillar of intelligent engineering. By adopting such technology, innovators are endowed with the ability to predict, adjust and thrive; molding the future for a specific and meaningful destiny.

In the time when brevity and swiftness are of the essence, CAE places engineers in a position to make decision on valid grounds and with confidence, for designs not only to be functional, but to also be brought up to The incorporation of advanced analytical tools like the structural, thermal and fluid dynamics simulations provide more insight with regards to product behavior during the initial operating environment.