As the design and engineering sectors continue to evolve, Computer-Aided Design (CAD), or computer aided design cad, cad software has found its place at the foundation of today’s creativity and accuracy, particularly for design engineers. or cad computer aided design has found its place at the foundation of today’s creativity and accuracy, particularly for design engineers . CAD is not just a simple digital drawing software, but a full suite of software technology, including various software packages, which enables designers, architects, and engineers to formulate, develop and renovate complex structures and systems with a whole new level of accuracy and flexibility in mind. In an era of growing industries’ dependence on digital innovation, CAD can be considered the link between the vision and reality.

Moreover, CAD has transformed the process of design enabling the designers to work in real-time with their colleagues and clients and make iterative changes to their design, which also eliminates the need for building physical prototypes which can be quite costly and long drawn out, thus reducing costs . CAD can simulate the real-world conditions and run stress tests to ensure that not only do the designs look good but they also possess a structural integrity and functionality. The combination with other sophisticated technologies (e.g. 3D printing, CNC machining) would only strengthen its place in the modern manufacturing methods as it would help provide a smooth transition from digital to physical models. While the industries are adapting to the digital transformation, CAD will be a rock of innovation that will allow designers and engineers to stretch the limits of what is possible, especially in additive manufacturing .

The Essence of Computer-Aided Design

Computer-Aided Design as a term is itself at the centre of it all, for it defines the use of specialized cad software applications, including aided design and drafting, to help create, modify, analyse and optimize the said detailed design. Instead of the traditional drafting methods, such as hand-rendered blueprints and physical models that were used in drafting, CAD allows the user to make complex drawings of cad models in both 2d and 3d and three dimensional models from an entirely digital space. of complex three-dimensional (3D) models from an entirely digital space. These models are not just figures. They provide relevant information about the target area and demonstrate the coming future. they can comprise dimensional data, material properties, stress tolerances, behavioral simulations, etc, – CAD is an integral part of intelligent design.

The difference between CAD and traditional draftsmanship is the fact that CAD can include dynamic parameters and functional relationships. A change in one part of a model will automatically propagate to modify all related dimensions and parts of the model, simplifying the design process and reducing the chances of inconsistencies. This efficiency is especially important in the engineering process when working on large-scale assembly design engineering projects, where dynamic analysis can be crucial, and utilizing advanced cad tools enhances productivity ., where dynamic analysis can be crucial, for which precision and flexibility, enhanced by 3d cad software, are important for outcome.

Applications Across Diverse Industries

CAD software, or cad software, has got applications across various industries, including construction managers who rely on it for detailed planning and 3d cad applications ., including construction managers who rely on it for detailed planning, and a wide span of industries, all with their distinct needs and complexities. The computer-aided design in architecture permits drawing of elaborate direction and structural layouts and encompasses anything from modest homes, to mammoth work of infrastructure. To visualize the spatial relationships, architects try to express themselves with cad models, make tests and perform lighting or environmental simulations “in one interface.”

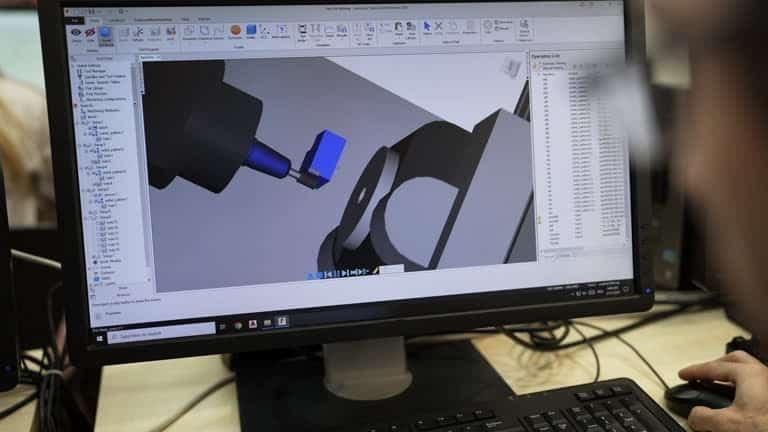

In mechanical and industrial engineering, particularly in product engineering In product design, CAD is an integral part of designing components, machinery, and assemblies. Engineers have the ability to design moving parts, test tolerance and confirm the functional compatibility of each component using various software packages. before any physical articles get created using computer based software . This virtual prototyping dramatically cut down on manufacturing errors related to real world products and quicken the time-to-market.

The aerospace industry and the automotive industry also gain immensely from CAD technologies. 3d cad tools allow engineers to model 3d models aerodynamics, structural loads, and system integrations with surgically precise accuracy., structural loads, and system integrations with surgically precise accuracy, especially for real world objects. , and these sectors require very high levels of accuracy to achieve precise designs . In fashion design and product design, more and more computer assisted design tools are used to mold aesthetics, ergonomics and branding coherence into concrete, producible commodities from abstract notions.

Advantages of CAD in the Modern Workflow

Computer-Aided Design has several advantages compared to the older manual drafting methods. One of its most transformative strengths is the ability to speed up the design process and either retain or enhance quality. Such cad software tools as automated dimensioning, pattern recognition, and technical drawings parametric modeling, alongside other software, allow the repeated tasks to be performed quickly with minimal mistakes. What used to take days or weeks to complete can now be done in hours through design iterations.

Furthermore, CAD improves collaboration and records. Complex projects usually imply various interdisciplinary working teams with geographically distant sites. CAD files can be shared, annotated, and edited in real time, allowing for smooth flow of contacts and integration.

Sustainability and cost-effectiveness are also encouraged by CAD. With the ability to make design scenarios and mirror real performance digitally, superfluous physical prototypes are now avoided. Not only does it save on material and energy, such as avoiding the waste of file formats like drawing interchange format and dxf files. but it also de-emphasizes the amount of environmental impact it leaves behind. Such simulations enable potential design defects and design intent to be identified at an early stage, ensuring accurate design data. , allowing users to make necessary adjustments. that will normally reduce the cost of production hence increase overall efficiency in additive manufacturing .

Challenges and Considerations in CAD Implementation

Although it has powerful advantages, the introduction of a robust cad system for computer assisted design CAD systems is less of a breeze. The initial setup cost for computer programs acquisition, software acquisition, licensing, and hardware upgrade requirements can be massive; most cad software especially given the need for interchange format compatibility, including the initial graphics exchange specification .. especially for smaller organisations or individual users. Also, the steep learning curve is required to master the advanced CAD tools including native cad files . Users have to invest time into proficiency development, especially if they are using complicated features such as solid edge, surface modeling, finite element analysis (FEA), or computer-aided manufacturing (CAM) integrations.

Effective data management also becomes an important issue in a design that has multiple design revisions and electronic files among collaborators. Lack of proper version control and organization may fail to ensure integrity of the project due to inconsistent and data loss. Consequently, the integration of CAD with Product Lifecycle Management (PLM) or Enterprise Resource Planning (ERP) systems, especially for project managers, is usually necessary. to maintain an effective data governance and continuity in the business flow for product designers .

The Evolving Future of CAD

The future of Computer Aided Design is currently under the influence of cutting-edge advances in artificial intelligence, cloud computing, and augmented reality. Nowadays, AI-assisted design tools start suggesting geometry optimizations, structural weaknesses, and even generating whole components, improving the overall design workflow and the exploration of design concepts . in both 2d and 3d cad software by user-defined objectives are specified. Such smart systems are making the CAD transition an active design association instead of passive drafting.

Meanwhile, CAD platforms are no longer based on the cloud with real-time collaboration and mobile access, dismantling the wall between the designers and manufacturers. By giving users the ability to be enveloped in their designs, virtually full scale, while they can digitally create 2d drawings. , augmented and virtual reality are also furthering the revolution of CAD, particularly in direct modeling by boosting spatial awareness and client interaction.

Conclusion

Equipment driven by precision and fortitude determines success nowadays; Computer-Aided Design is also used for electronic systems and has become an edifice of contemporary ingenuity. It is not just a tool, but it is a dynamic ecosystem platform that ties together creativity and functionality, such as in the creation of a wireframe model . Advancements in technology will only increase the potential of CAD for civil engineers – imaginability and implementation will become inseparable. For designers, engineers, and innovators too, marrying up with CAD is not a choice but a necessity if you must survive in the digital era of design.

As CAD continues to develop, its integration into the emerging technologies such as Artificial Intelligence, Machine Learning and Virtual reality will transform the concept of design and production. These improvements will allow even more detailed simulations using computer aided design models and automatized optimizations and provide more immersive design experiences, virtually ceasing the differences between the abstract and real. For any profession, implementing computer aided design cad, including aided design and drafting, is not only a way to keep up with the competition but also to redefine the boundaries of possibilities, so that all the choices are made on the basis of data-driven insights and instant-time details. In the dynamic world of contemporary innovation, computer aided design systems like CAD are tools, as well as strategic resources which cannot be overlooked to determine the future of design and production.