Die casting is high productivity and high precision process, sometimes referred to as precision casting, which provides a way of forming complex parts of extraordinary dimensional accuracy by using moulds for injecting molten metal therein, making it ideal for high volume production. which provides a way of forming complex parts of extraordinary dimensional accuracy by using moulds for injecting molten metal therein, making it ideal for high volume production . Dies casting dies play a vital part of this process as dies themselves are the molds or tools that are used to create final products. These are precisely engineered to handle the high pressure and temperatures of the die casting process endowing parts manufactured using these dies a smooth surface, tight tolerances, and low defects.

The materials used for making die casting dies are high-grade tool-steels that can withstand high levels of thermal and mechanical stresses of casting. Such steels are chosen for its strength, toughness and resistance against abrasion and thermal fatigue, which allow long die life and part quality in high pressure die casting . Further on, die design is very important to the success of the process, whereby attention must be paid to details, in the quest of such areas as cooling channels, venting systems, and part ejection mechanisms. Well designed dies not only save in production efficiency but also increase the general structural strength and surface appearance of finally cast components.

This article identifies the concept of die casting dies, materials and design factors, types of dies and importance to the die casting industry, including various die casting variations, and manufacturing industry. Also it will emphasize proper die maintenance/care to provide consistent quality and longevity of die casting tools.

What Are Die Casting Dies?

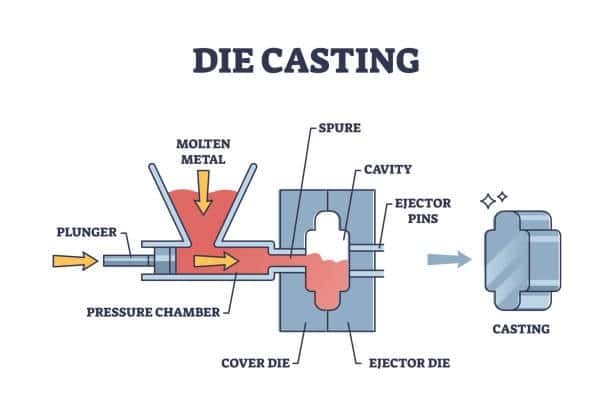

A die casting die is a metal mold that is used during die casting to melt and mold molten metal to take specific forms. These dies are designed in such a manner that they allow for quick metal solidification, post its molten state leading to the formation of high-precision parts as molten metal fills the die with very complex shapes and intricate complex geometries. The typical dies used in die casting are built with fabrications that can stand the heat and pressure that result from the process.The die casting die is made of two major components: the core and the cavity. The cavity of the part has the outer shape and the core has the inner shape of the part. The two halves of the die are pressed during the casting to let molten metal pour in into the mold. After solidification of the metal, the die is opened and the finished part ejected.

Apart from core and cavity other auxiliaries are found in a die casting for functionality purposes and product quality. These can be ejector pins used to remove parts, runners and gates that channel the flow of molten metal, and cooling channels that control temperature through casting. Thermal control is important considering that it will ensure uniform solidification and reduce internal stresses or shrinkage defects. In addition, dies can have venting systems to allow trapped gases to vent out thus reducing the chances of porosity on the final product, ensuring high-quality cast metal . These complex parts combine to give the die casting a high accuracy as well as repeatability to make it favorable in mass production of complex metal parts with thin walls in industries.

Types of Die Casting Dies

The die casting dies have various kinds depending on the type of multiple applications a die casting manufacturer must consider nd manufacturing requirements. These types can be classified on their design and the use they have in various industries, including the production of steel components .

1. Hot Chamber Dies

Hot chamber die casting is normally applied to metals with low melting points, including zinc, magnesium, and some varieties of aluminum alloys. In hot chamber die casting, the injection mechanism is submerged in the molten metal, making the hot chamber machine appropriate for high-speed small parts casting. The die is intended to withstand repeated exposure to high temperatures with metal being injected into the die under considerable pressure.

Advantages of Hot Chamber Dies:

- Fast cycle times.

- Precision at the small detail level.

- Suitable for low melting point metals.

2. Cold Chamber Dies

Cold chamber die casting is used for metals with high melting point including the aluminum, brass, and copper alloys. In cold chamber die casting, molten metal is poured into the separate chamber, before going through the die under elevated pressure. This approach is widely applied in businesses where parts of high performance and durability, such as aluminum die casting. , such as die cast aluminum parts, are needed for example in automotive and aerospace industries.

The cold chamber die casting is especially useful in the case of metals that would otherwise corrode or impair the injection processes of hot chamber system. The process has slightly longer cycle times on account of separate loading of molten metal, but enables casting of larger and more structurally demanding components. The application of high pressure injection of molten aluminum guarantees that even complicated shapes with small details and narrow tolerances are obtained. In addition, cold chamber die casting ensures excellent mechanical properties in the final parts, in terms of increased strength and thermal resistance, which is essential for systems that need robust long-term reliability and safety.

Advantages of Cold Chamber Dies:

- Suitable for high-melting-point metals.

- Stronger, more durable parts.

- Has multiple materials compatible.

3. Semi-Solid Die Casting Dies

Semi-solid die casting an intermediary technique that combines an aspect of hot and cold chamber die casting. This process involves injection of metal in semi solid state; an improvement of flowability of liquid metal and probably then it handles the defect like porosity and shrinkage. Semi-solid die casting is best suited to produce aluminum parts and complicated parts with higher integrity of material and is being continuously adopted by industries such as automotive and electronics.

Semi-solid die casting offers one of the main advantages associated with the process namely, it is able to decrease turbulence during metal injection, thus, greatly minimizing air entrapment and the defects that are caused by it. Since the metal is partially in solid state before it enters the die, it possesses thixotropic properties – flows due to pressure but remains as stable as possible otherwise – that make it possible to control filling and solidifying with high precision. This leads to parts with better dimensional stability, better surface finish, and a small number of after-manufacturing operations. In addition, the reduced injection temperatures in semi-solid casting also means longer die life and reduced energy consumption, which progressively makes it a desirable alternative to expensive high-performance cost-conscious manufacturing processes including techniques like metal stamping .

Advantages of Semi-Solid Die Casting Dies:

- Enhanced material proprieties and part integrity.

- Reduced porosity and shrinkage.

- Ideal for creating complex geometries.

Materials Used for Die Casting Dies

Material selection for die casting mold and die cast dies is important to the tool operation, durability and life span. Die casting dies have to be heat resistant, wear resistant, and burn resistant, including those made from carbon steel, yet maintain dimensional accuracy after long term repetitive cycles. Commonly used die casting die materials are:

1. Tool Steel

Tool steel is the most popular die casting die material because of it’s strength, hardness and resistance to wear. It can stand the high temperatures and pressures that occurring during die casting, unlike the sand casting process . Those tools steels including H13 and P20 are sensible ones having high thermal stability as well as toughness.

Tool steels of the type H13 are particularly sought after in die casting because of the property combination of good hot hardness, thermal fatigue resistance, and machinability, as they are perfectly suited for regular use under extreme circumstances. H13, for example, remains strong and structurally intact even when it has been exposed to high temperatures for extended periods of time, hence minimizing cases of die cracking or warping. As for P20, it is a widely applied material for less challenging applications with good polishability and average strength. The right choice and heat treatment of a tool steel are essential for achieving optimal performance and durability of dies and, consequently, the efficiency, quality, and cost-effectiveness of the die casting operation as well.

Advantages of Tool Steel:

- High strength and wear resistance.

- Excellent thermal conductivity.

- Long service life.

2. High-Speed Steel (HSS)

Another material used for die casting dies in high-speed steel in particular when great details are a must and high precision results desired, often utilizing ceramic mold techniques . HSS provides good hardness and resistance to deformation under high temperatures and is applicable to produce details parts.

High-speed steel (HSS) is especially important in die casting applications that would require intricate detail with tight tolerances, especially in small or intricate pieces. Its outstanding hardness and ability to retain strength at high temperatures make it appropriate for designing dies that have to withstand continuous thermal cycling and mechanical stress. HSS also has exceptional wear resistance, which means that fine details of the die are preserved down the line as the discrete casting cycles repeat, guaranteeing continued accuracy. It is more expensive than other materials, but it is often more than capable of paying for itself through performance on high-precision or special applications where dimensional tolerance and surface finish are important.

Advantages of High-Speed Steel:

- Exceptional hardness at high temperatures.

- Applicable to precision and complicated type of molds.

- Good wear resistance.

3. Stainless Steel

Die casting dies commonly use stainless steel because of its resistance to corrosion, tensile strength and can endure the coarse environment of the die casting process, including zinc die casting . Although stainless steel does not compare in durability to tool steel, but it is an ideal choice for uses where the need for resistance to corrosion is high, such as in culinary production or manufacturing the medical devices, as opposed to lost wax casting.

Stainless steel is very effective especially in die casting systems where the exposure to the moisture, chemicals or the sterilisations processes is often the case and therefore it calls for the resistance to the corrosions. By being able to resist rust and keep structural integrity, it is ensured that the die remains in a clean, uncontaminated state – important in uses such as food, pharmaceuticals, medical instruments. Although it may be eroded faster, than tool steel in the extreme pressure and temperatures of high volume die casting; the biocompatibility and hygenic nature of stainless steel often make it the choice material for the more specialized, or for those of lower output where cleanliness and resistance to oxidation are important.

Advantages of Stainless Steel:

- Corrosion resistance.

- Durability in various environments.

- Perfect for low to medium volume production.

Design Considerations for Die Casting Dies

The design of the die casting dies play a very important role in terms of production of high quality parts and reduction of the overall die casting process. Certain points to consider while designing die casting dies involve:

1. Part Geometry and Complexity

The geometry of the part geometry has to be taken into account when designing the die. Complex parts may need some other features including cores, inserts, and/or cooling channels to make the proper molding possible. Die design should facilitate the flow of molten metal into the die cavity and allow part easily to be ejected when the casting is finished.

Proper die design also entails studying such aspects as draft angles, those of parting, and wall thickness to eliminate instances of casting defects and allow smooth ejection of the finished component from casting machines . Draft angles play a significant role in ensuring the parts have reduced friction as they are removed from the die hence reduced wear on die and no damage to cast piece. Optimally located parting lines allow for fast die separation and precise forming of parts with no need for engineering changes, and consistent wall thickness serves to prevent such problems as warping or sink marks because of non-uniform cooling. Also, using effective venting system as well as overflow wells can further enhance the metal flow and eliminate the possibility of air trapping or incomplete fills resulting in good quality castings with less rejection rate.

2. Heat Management

Heat management plays a key role in avoiding warping, cracks or parallax and dimensional errors. Design of die casting dies must be in a manner that they cool heat waste effectively during the cooling process. In many cases, the die design is provided with cooling channels to regulate the rate of solidification and promote uniform cooling.

Swift heat management not only ensures dimensional stability but also increases the life of the die as it reduces thermal fatigues and stress build-ups. Cooling channels are placed strategically in the die to take heat from essential regions so as to achieve a uniform temperature during the casting cycle. In some sophisticated die designs, conformal cooling, special shaped channels which follow the geometry of the cavity closely, is utilized in order to further improve the control of the heat. Additionally, the thermal simulations are commonly used in the design stage to determine heat flow and positioning of channels to achieve the best cycle times, product quality, and productivity in the operation of casting machines .

3. Ejection System

A successful ejection system is necessary to remove the cast part from the die without destroying or distorting it. The design of the ejection system should take care of the shape of the part and should ensure that the ejected part is ejected evenly and smoothly.

A good ejection system usually includes ejector pins, sleeves, or plates that are carefully positioned along the part to be ejected so that it does not get damaged in the process while it is removed. The placement of ejectors and the number of ejectors have to be well-calculated with respect to part geometry and thickness in order to allow for even distribution of ejection force. In addition, the ejection system should be designed to reduce the cycle time since it entails fast and reliable part release with minimal downtimes and higher productivity. Appropriate maintenance and positioning of the ejection components are also very essential in maintaining the constant part quality and even extending the die life, and the machines’ operation life.

Maintenance of Die Casting Dies

Proper maintain of die casting dies will ensure their longevity and their performance. With time dies can wear or corrode or crack which may have negative effects on the quality of cast made. Normal servicing of dies by inspection, cleaning and lubrication, and repair and replacement on time helps in maintaining the normal capacity and life of the die casting mold.

A routine for regular maintenance of the die casting machine does not only avoid unforeseen downtime but also helps in identifying early indications of wear and damage before they become expensive failure. Examples of techniques that can do this include nondestructive testing where cracks or internal flaws can be detected, and precise cleaning which removes residue or build-up which may have an impact on the die’s surface finish or dimensional accuracy. Moving part lubrication minimizes friction and wear hence smoother operation in the casting cycles. Also, prompt repair or replacement of worn components maintains the dies in the state of maximum efficiency, that eventually promotes the consistency and quality of the end cast parts while achieving optimum return on the tooling investments.

Conclusion

Die casting dies are the building blocks of the die casting processes and produce a variety of metal parts with the right shapes and forms. Well designed and maintained die casting dies for selecting a proper material can produce high precision parts, strong and complex pieces for a range of industries, in the broader context of the metal casting process. Whether used for low-volume small production or complex high performance elements, die casting dies guarantee that the process of manufacturing is efficient and dependable in the overall manufacturing process .

The selection of die material as well as proper design and in-depth upkeep of the die casting operation directly affect its overall productivity and cost-effectiveness. Its advances in die technology; the better cooling systems and surface treatments are among other such advances that have continued to improve die performance and part quality. As industries continue to require more elaborate and trustworthy metal parts, die casting dies play even greater importance in spurring innovation and precision production. In the end the bottom line is for investment in good-quality dies for quality end products, quick turnaround times and minimal waste to make die-casting the choice method for mass production in various industries.