The Evolution of EDM Wire Machining

Electrical Discharge Machining (EDM), utilizing an electric spark, has transformed the manufacturing landscape since its inception in the 1940s. The technology emerged from the discovery that electrical sparks could remove material in a controlled manner. What began as a rudimentary process has evolved into one of the most precise metal-cutting technologies available today. Wire EDM, specifically, has become indispensable in modern manufacturing facilities worldwide.

The journey of EDM wire machining began with the work of Soviet scientists B.R. and N.I. Lazarenko, who developed the basic EDM process during World War II, which is now critical in the aerospace industry . However, it wasn’t until the 1960s that wire EDM systems became commercially viable. The subsequent decades saw remarkable advancements in control systems, wire materials, and machining capabilities that have propelled this technology to its current sophisticated state.

Understanding the Fundamental Principles of Wire EDM

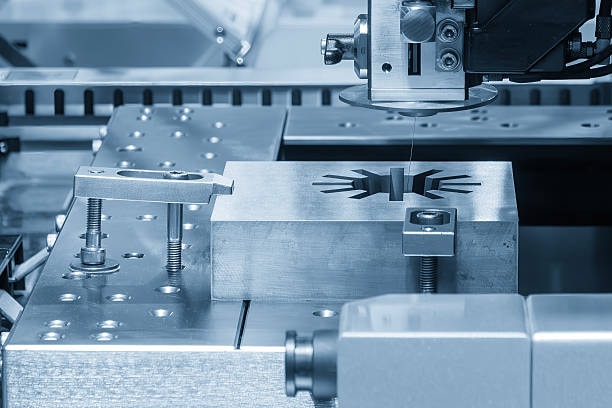

Wire Electrical Discharge Machining (WEDM) operates on a deceptively simple principle: wire erosion through the controlled erosion of material via electrical discharges. Unlike conventional machining processes that rely on physical contact between tools and workpieces, wire EDM is a non-contact thermal process that removes material through a series of rapidly recurring electrical discharges.

In this process, a thin wire (typically between 0.1 and 0.3mm in diameter) serves as the workpiece electrode. The wire and the workpiece are separated by a dielectric fluid, usually deionized water. When electric current voltage is applied, an electrical discharge occurs across the gap, creating a plasma channel that generates intense heat (up to 12,000°C). This heat vaporizes tiny particles of the workpiece material, which are then flushed away by the dielectric fluid. The wire never actually touches the workpiece, maintaining a spark gap of approximately 0.02-0.05mm.

Key Components of a Wire EDM System

A typical wire EDM system consists of several critical components that work in harmony to achieve precision cutting:

- Wire Electrode – Usually made of brass, copper, or coated materials, this consumable component is continuously fed through the cutting area.

- Wire Feed System – Controls the movement of the wire from the supply spool through the workpiece and onto the take-up spool.

- Power Supply – Generates the electrical discharges necessary for cutting.

- Dielectric System – Circulates deionized water around the cutting zone to flush away debris and cool the process.

- CNC Control System – Directs the precise movement of the wire according to programmed instructions.

- Work Table – Securely holds the workpiece in position during machining.

- Automatic Wire Threading System – In modern machines, this allows for unattended operation by automatically rethreading the wire in case of breakage..

Each component plays a vital role in ensuring the accuracy, reliability, and efficiency of the wire EDM process.

Advantages of Wire EDM Over Traditional Machining Methods

Wire EDM offers numerous advantages that make it the preferred choice for certain applications:

Exceptional Precision: Wire EDM can achieve tolerances as tight as ±0.0001 inches (2.5 microns), making it ideal for high-precision components.

Complex Geometries: The process can create intricate shapes that would be impossible or prohibitively expensive with conventional machining methods.

No Direct Contact: Since there is no physical contact between the cutting tool and the workpiece, there are no mechanical forces that could distort delicate parts, unlike conventional machining techniques .

Material Versatility: Wire EDM can effectively cut any electrically conductive material regardless of hardness, including hardened steel, titanium, and exotic alloys.

Burr-Free Results: The process typically produces parts with minimal or no burrs, reducing or eliminating secondary finishing operations.

Heat-Affected Zone Management: Modern wire EDM systems can be tuned to minimize the heat-affected zone, preserving the material’s properties and enhancing overall quality control .

Automated Operation: Advanced machines can run unattended for extended periods, improving productivity and reducing labor costs.

These advantages have made wire EDM an essential technology in industries requiring high precision, tight tolerances, and complex geometries.

Material Considerations for EDM Wire Machining

The success of wire EDM operations depends significantly on understanding material properties and selecting appropriate parameters:

Conductivity Requirements: The workpiece must be electrically conductive. Materials with higher conductivity generally machine faster.

Material Thickness: As material thickness increases, cutting speed typically decreases. Very thick materials may require special techniques or multiple passes.

Thermal Properties: Materials with high thermal conductivity dissipate heat quickly, potentially affecting cut quality and speed.

Surface Finish Expectations: Different materials respond differently to EDM parameters, affecting the achievable surface finish.

Material Composition: Alloys with volatile components may require special considerations to manage fume generation and prevent wire breakage.

Common materials processed via wire EDM include tool steels, stainless steels, aluminum, copper alloys, titanium alloys, carbides, and conductive ceramics. Each material demands specific parameter adjustments to optimize cutting performance.

Wire Types and Selection Criteria

The wire electrode is perhaps the most critical consumable in the EDM process, along with the dielectric liquid with various options available:

Brass Wire: The most commonly used wire due to its good conductivity and reasonable cost. Standard brass wire (typically 63% copper, 37% zinc) offers a balance of performance characteristics suitable for most applications.

Stratified Wire: These wires feature a brass core with a zinc-rich outer layer, acting as a tool electrode providing improved flushing and cutting speed.

Coated Wire: Wires with specialized coatings (often zinc) offer enhanced cutting speed and improved corner accuracy.

High-Tensile Wire: Specially developed wires with greater tensile strength allow for more accurate cutting, particularly in tall workpieces.

Molybdenum Wire: Used for specialized micro-machining applications due to its high tensile strength at small diameters.

Wire diameter selection typically ranges from 0.05mm to 0.3mm, with the choice depending on the required corner radii, cutting speed requirements, and part features. Smaller diameter wires produce tighter corners but may cut more slowly and be more prone to breakage.

Dielectric Fluids in Wire EDM

In wire EDM, deionized water serves as the primary dielectric medium, fulfilling several critical functions:

Spark Insulation: The dielectric fluid maintains insulation between the wire and workpiece until voltage reaches the breakdown point.

Debris Flushing: It carries away the eroded material particles to prevent them from interfering with subsequent discharges and minimize wire burning .

Cooling: The fluid helps dissipate heat generated during the cutting process.

Wire Stability: Proper fluid flow helps stabilize the wire during cutting, reducing vibration.

Modern wire EDM systems continuously monitor and adjust the conductivity of the deionized water through filtration and ion exchange systems. Water quality is critical, as contamination or improper conductivity can lead to unstable cutting conditions, poor surface finish, or wire breakage.

Programming and CAM Systems for Wire EDM

Effective programming is essential for maximizing the capabilities of wire EDM systems:

CAD/CAM Integration: Modern wire EDM relies heavily on CAD/CAM software to generate toolpaths from 3D models or 2D drawings.

Wire Path Optimization: Advanced software can optimize wire paths to minimize cutting time and improve part quality.

Technology Databases: These contain pre-established cutting parameters for various materials and thicknesses, streamlining the programming process.

Adaptive Control: Some systems continuously monitor and adjust cutting parameters in real-time based on actual cutting conditions.Simulation and Verification: Virtual simulation allows operators to verify programs before actual cutting, reducing the risk of errors.

Most wire EDM machines use G-code or proprietary formats to control machine movements. Programming skills remain valuable despite automation advances, as experienced programmers can optimize cutting strategies for specific applications.

Wire EDM Process Parameters and Optimization

Achieving optimal results with wire EDM requires careful attention to numerous process parameters to attain the desired shape :

Discharge Energy: Controlled by peak current, voltage, and pulse duration, this determines material removal rate and surface finish.

Pulse Frequency: Higher frequencies generally produce finer finishes but may reduce cutting speed.

Wire Tension: Proper tension maintains wire straightness and accuracy but must be balanced to prevent breakage.

Wire Feed Rate: The speed at which the wire moves through the guides affects cutting performance and wire economy.

Flush Pressure and Flow Rate: Proper flushing ensures efficient debris removal and stable cutting conditions.

Servo Reference Voltage: Controls the average gap distance between the wire and workpiece.

Offset Values: Compensate for the wire diameter and spark gap to achieve desired part dimensions..

Optimization often involves a trade-off between cutting speed, surface finish, and accuracy. Modern machines frequently offer technology packages with pre-optimized parameter sets for common applications.

Surface Finish and Accuracy Considerations

Wire EDM is renowned for its ability to achieve exceptional surface finish and dimensional accuracy:

Surface Roughness Control: Wire EDM typically produces surface roughness values from Ra 0.05μm to 3.0μm, depending on the number of finishing passes and parameter settings.

Multiple Pass Strategies: Most precision work involves a roughing cut followed by one or more finishing passes with reduced energy levels.

Corner Compensation: Special techniques compensate for the natural tendency of the wire to deflect slightly around corners.

Thermal Expansion Management: Temperature stability is critical for maintaining accuracy, with some high-precision machines featuring temperature-controlled environments.

Wire Lag Compensation: Advanced controllers account for the slight lag of the wire behind its programmed position, particularly in thick materials, distinguishing it from conventional cutting tools .

Achieving the highest levels of accuracy often requires careful consideration of environmental factors, material preparation, and proper machine warm-up procedures.

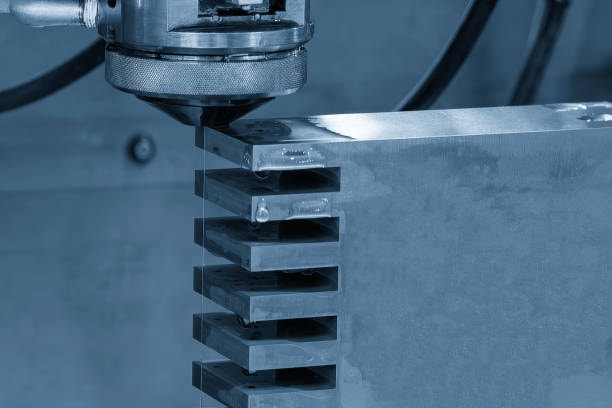

Multi-Axis Wire EDM Capabilities

While basic wire EDM machines operate in 2-axis (X and Y) mode, advanced capabilities are available on modern systems:

4-Axis Machining: By adding U and V axes (which control the upper wire guide independently from the lower guide), machines can create tapered cuts and complex geometries.

Multi-Contour Cutting: Advanced control systems allow for different geometries at the top and bottom of the cut, creating complex 3D forms.

Rotary Axis Integration: Some specialized systems incorporate rotary tables to enable cylindrical or indexing features.

Wire Rotation: Certain advanced machines can rotate the wire itself to improve cutting performance in specific applications.

These multi-axis capabilities have expanded the application range of wire EDM, allowing for the production of complex molds, dies, and precision components that would be impossible with simpler systems.

Industry Applications of Wire EDM Technology

Wire EDM has become indispensable across numerous industries:

Tool and Die Manufacturing: Creating punches, dies, and mold components with precision and complex geometries.

Aerospace: Producing turbine components, honeycomb structures, and specialized fittings from exotic alloys.

Medical Device Manufacturing: Fabricating surgical instruments, implant components, and precision medical devices.

Electronics: Creating connector pins, lead frames, and intricate parts for electronic assemblies.

Automotive: Manufacturing fuel injection components, transmission parts, and specialized tooling.

Jewelry and Watchmaking: Producing intricate components for high-end watches and custom jewelry.

Micro-Machining: Creating tiny parts for various industries, including medical devices and electronics.

The versatility of wire EDM makes it valuable anywhere precision, complex geometry, and difficult-to-machine materials converge.

Recent Technological Advancements in Wire EDM

The field of wire EDM continues to evolve with several notable advancements:

Digital Generator Technology: Modern power supplies offer unprecedented control over spark characteristics, improving surface finish and cutting speed.

Intelligent Adaptive Control: Advanced monitoring systems adjust parameters in real-time based on cutting conditions.

Anti-Electrolysis Technology: Specialized power supply features that minimize the electrolysis effect in certain materials.

Ultra-Fine Wire Capability: Some machines can now use wire diameters as small as 0.02mm for micro-machining applications.

Eco-Friendly Solutions: Energy-efficient machines with reduced water and wire consumption address sustainability concerns.

Automation Integration: Seamless integration with robotic handling systems and automated tool changers increases productivity.

AI and Machine Learning: Emerging systems that learn from past operations to optimize cutting parameters automatically.

These technological developments continue to extend the capabilities and efficiency of wire EDM systems, addressing previous limitations and opening new application possibilities.

Environmental and Safety Considerations

Operating wire EDM systems requires attention to several environmental and safety aspects:

Water Treatment: Proper filtration and disposal of used dielectric water, which may contain metal particles and deionization resins.

Energy Consumption: Modern machines incorporate energy-saving features to reduce power requirements during idle periods.

Wire Recycling: Programs for recycling used wire to recover valuable metals and reduce waste.

Ventilation Requirements: Adequate ventilation to manage any fumes generated during the cutting process, particularly with certain materials.

Electrical Safety: Proper grounding and electrical safety protocols to prevent accidents with high-voltage systems.

Machine Guarding: Safety interlocks and guards to protect operators during operation.

Industry best practices include regular maintenance of filtration systems, proper disposal of consumables, and operator training on safety procedures.

Maintenance and Troubleshooting

Proper maintenance is essential for reliable wire EDM operation:

Regular Calibration: Periodic checking and adjustment of positioning accuracy and squareness.

Guide Maintenance: Regular inspection and replacement of wire guides to maintain cutting accuracy.

Filtration System Service: Regular replacement of filters and deionization resins to maintain water quality.

Power Supply Checks: Verification of electrical components and connections to ensure stable power delivery.

Common Issues and Solutions:

- Wire breakage: Often resolved by adjusting cutting parameters or improving flushing conditions.

- Poor surface finish: Typically addressed through parameter adjustments or improving water quality.

- Dimensional inaccuracy: May require machine calibration or parameter optimization.

- Unstable cutting: Often related to flushing issues or wire feed problems.

Preventive maintenance schedules based on machine usage help minimize downtime and maintain cutting quality.

Cost Considerations and ROI Analysis

When evaluating wire EDM as a manufacturing solution, several cost factors must be considered:

Initial Investment: Wire EDM machines represent a significant capital expense, with prices ranging from $80,000 for basic models to over $300,000 for advanced systems.

Operating Costs: Including wire consumption (typically $2-8 per hour), electricity, deionized water, filters, and maintenance parts complex shapes.

Labor Requirements: Modern machines require skilled operators, though automation has reduced direct labor needs.

Production Speed: While wire EDM is slower than some conventional processes, it often eliminates secondary operations, reducing overall production time.

Quality Benefits: Reduced scrap rates and higher precision can offset higher per-hour operating costs.

Capability Expansion: The ability to process hardened materials and create complex geometries may open new market opportunities wire edm cutting.

When properly implemented, wire EDM typically offers strong return on investment through enhanced manufacturing processes capabilities, reduced secondary operations, and the ability to produce components that would be impossible or prohibitively expensive with conventional machining edm wire cutting.

Future Trends in EDM Wire Machining

The future of wire EDM looks promising, with several emerging trends:

Integration with Industry 4.0: Increased connectivity, data collection, and remote monitoring capabilities.

Hybrid Manufacturing Systems: Combinations of wire EDM with other processes in single machine platforms electric discharge machining.

Sustainable Technologies: Continued development of eco-friendly solutions with reduced resource consumption wire edm machining services.

Micro and Nano EDM: Further refinements enabling machining of increasingly smaller features.

New Wire Materials and Coatings: Development of specialized wire electrodes for specific applications.

Smart Factories: Integration of wire EDM into fully automated production cells with minimal human intervention.

AI-Driven Process Optimization: Advanced algorithms that continually improve cutting strategies based on accumulated data.

These trends suggest wire EDM will remain at the forefront of precision manufacturing technology, continuing to evolve to meet the demands of advanced industries.

Conclusion

Wire EDM has established itself as an indispensable technology in modern manufacturing, offering unparalleled precision and capabilities for metal components that conventional machining processes cannot match. From its ability to cut hardened materials with microscopic precision to creating complex geometries without mechanical forces, wire EDM continues to enable innovation across numerous industries.

As materials become more exotic, tolerances tighter, and geometries more complex, the importance of wire EDM in the manufacturing ecosystem will only increase wire edm services. The ongoing technological evolution of wire EDM systems—with improvements in automation, control systems, environmental performance, and integration capabilities—ensures that this technology will remain relevant and valuable for decades to come.

For manufacturers seeking competitive advantage through precision, quality, and capability, wire EDM represents not merely a machining process but a strategic technology investment that can transform production possibilities and open new market opportunities wire cut edm.