The ability to design and build a precision mold should be considered in terms of the engineering capacity and process discipline and not the marketing slogans or single machining accuracy. Most OEMs consider suppliers based on the fragmented requirements, including equipment lists or first quotes, that do not consider how the supplier might cope with the complex interactions throughout the life of the mold. Between superficial indicators, in most cases, cannot be predictive of long-term performance, as trouble in such indicators as dimensional drift or non-regular cycles will show up only after the long-term use. Most OEMs believe that it is only advanced machines or certifications that reflect the ability of a precision mold manufacturer, whereas the actual ability is in engineering discipline and process control. A precision mold manufacturer can be tested according to how well this is done across all of the lifecycle stages of the design intent and risk management.

Why Precision Mold Manufacturer Evaluation Is Often Misleading

The judgment of precision manufacturers of molds is often deceptive as it does not focus on the performance indicators that lie beyond the surface.

Overreliance on Machine Lists and Factory Size

It is commonplace to see OEMs obsessed with the kinds of CNC machines or the size of the facility that the size may indicate capabilities but tell little about process integration or error control.

The Limitations of Equipment-Focused Reviews

Even in my sourcing audits where it was evident that suppliers had great machines, the delivery of molds was erratic because of bad calibration practices.

Why Certifications Do Not Guarantee Execution Quality

Certifications such as ISO 9001 ensure there are systems in place but not the effectiveness with which they are implemented; audits might not identify the loopholes that exist in the day-to-day running of a company.

Beyond Certification Compliance

I have certified suppliers but I discovered that there are lapses in traceability which led to batch variations down the line.

The Difference Between Apparent Capability and Actual Performance

There is a difference between apparent ability such as shiny showrooms or sample parts and actual performance where actual tests are those done in the real world in sustained runs under varying conditions.

Identifying Performance Gaps Early

The request of process capability information (CpK) across time has identified differences in appraisals that I have conducted.

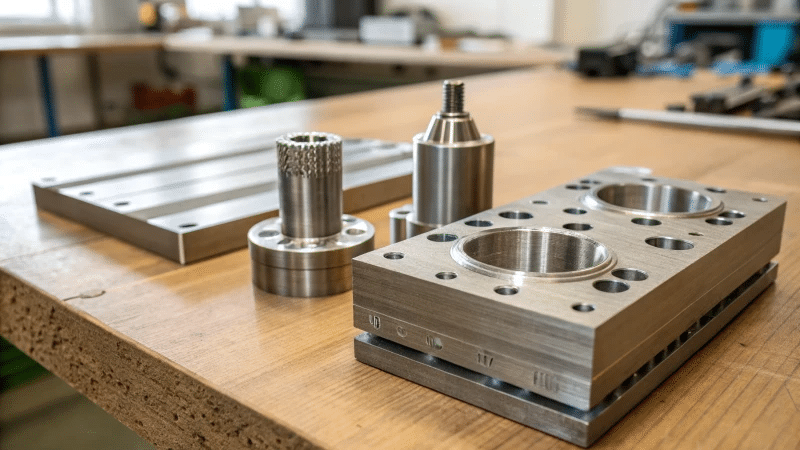

Defining Precision Before Evaluating Capability

OEMs should establish the meaning of precision, in functional terms, before assessing a supplier so that the expectations can be matched with the actual requirements.

Why OEMs Must Define “Precision” in Functional Terms

Precision is not a narrow tolerance, but rather functional consistency, that is, remaining in line and running under production conditions.

Functional vs Nominal Definitions

In electronics programmes, specifying precision as assembly fit maintained throughout 500,000 cycles helped in making more appropriate supplier decisions.

Relationship Between Tolerance, Performance, and Stability

Tolerances are useful in supporting performance provided they consider the aspect of stability; generalized specs result in over promise by the suppliers without delivery.

Linking Specs to Outcomes

Flexible definitions in my automotive credentials led to molds that were within original specifications but drifted which influenced yield.

Why Vague Definitions Lead to Poor Supplier Selection

Unclear specificity creates a wrong fit in suppliers; specific criteria will sift out those who have demonstrated stability. This ties into precision mold definition criteria, where functional benchmarks separate capable from average.

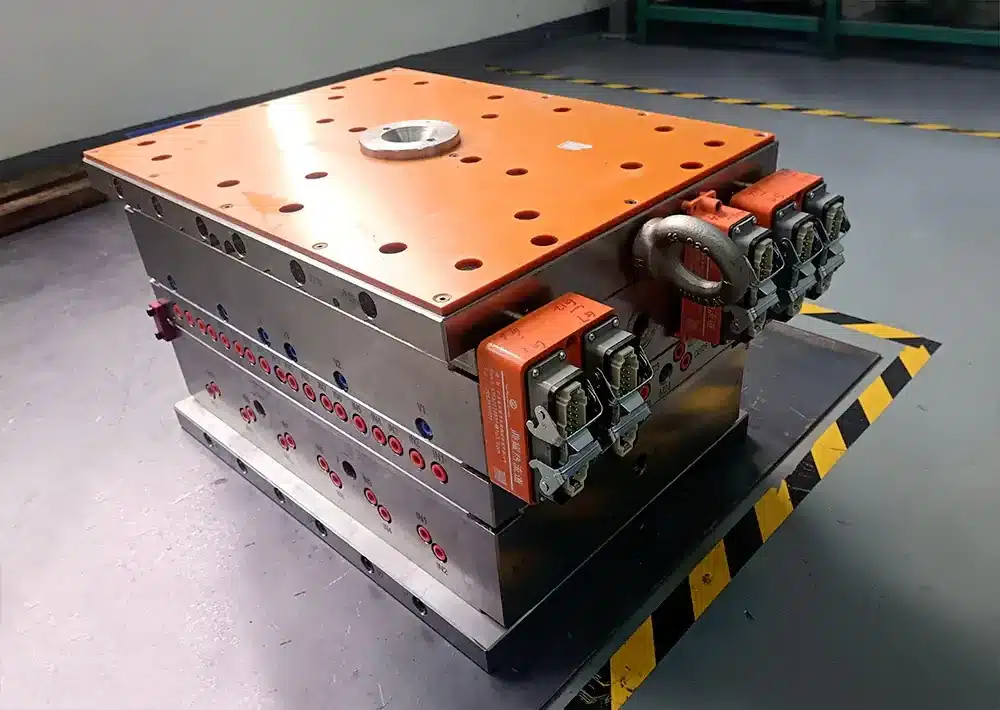

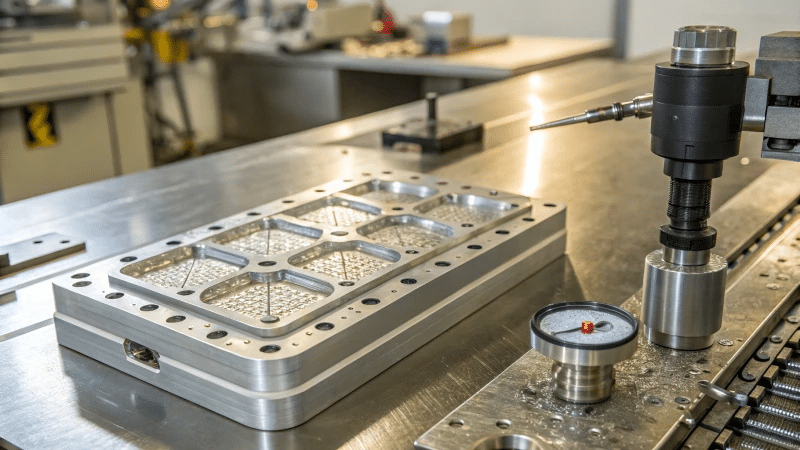

Core Engineering Capabilities OEMs Should Verify

The essence of engineering attributes would demonstrate that a supplier can turn design into a tool that would work, not just on paper.

Design Intent Interpretation

Check supplier interpretation and refinement of design – does it challenge ambiguity or model flow to maintain intent?

Assessing Interpretation Depth

During the medical sourcing, suppliers that ignored thermal effects were discovered during probing refinement processes.

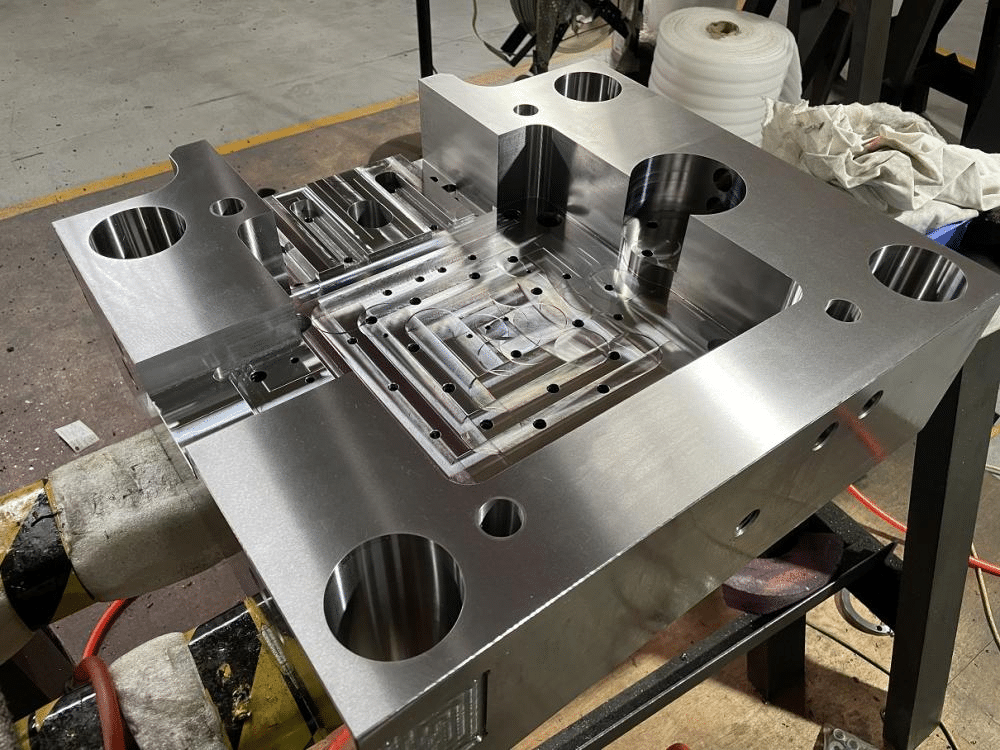

Tolerance Strategy and Lifecycle Planning

Comparison of tolerance strategies- functional and nominal- and their wear planning, to make specs maintain life.

Lifecycle-Focused Strategies

Wear modeling suppliers that were tested in my assessments were more dependable when it comes to high volume requirements.

Cross-Functional Engineering Coordination

Between design, machining, and quality Check coordination silos are indicative of risks. This is central to precision mold engineering capability, where integrated teams mitigate errors.

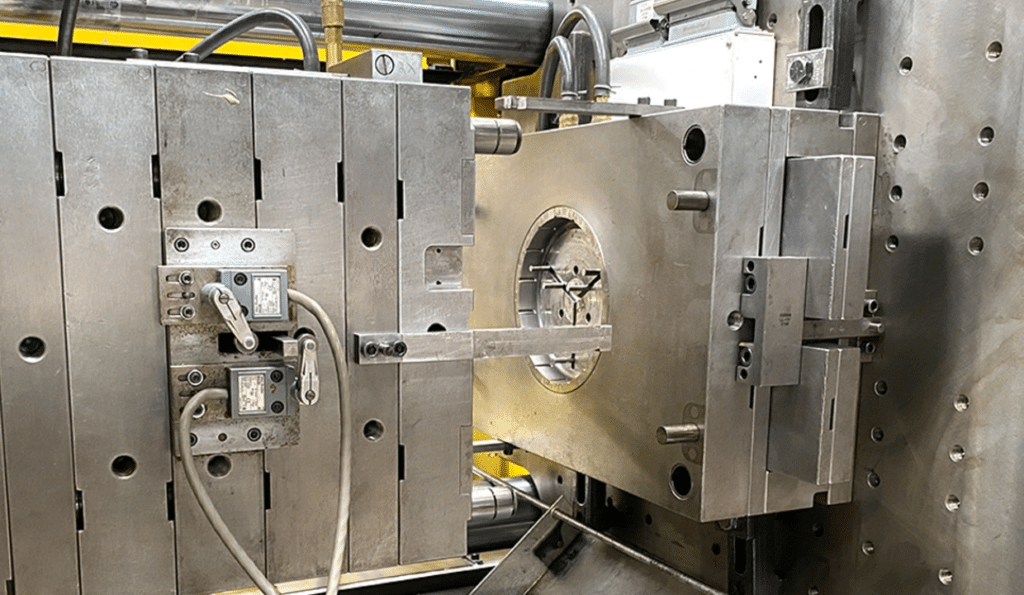

Process Discipline Matters More Than Individual Machines

The discipline of processes, the discipline of constancy, is more important than machine specifications, since it regulates the variability in builds.

Why System Control Outweighs Isolated Machining Accuracy

Systems provide repeatability; isolated accuracy cannot work without such controls as SPC to check drifts.

System vs Tool-Centric Evaluation

System audit in the e-qualification of electronics found that variability existed in the shadow in spite of sophisticated instruments.

Importance of Documentation, Feedback Loops, and Revision Control

Changes are documented; feedback allows processes to be improved; bad management results in nonreproducible builds.

Building Reliable Loops

My reviews had suppliers who had strong revision systems that minimized defects by early detection.

How Disciplined Processes Reduce Variability

The shots are reduced, shot-to-shot differences are reduced, and discipline keeps the production at the same level, whereas lax processes increase the risks.

Variability Reduction in Practice

Regular procedures by the automotive suppliers reduced my validation periods and this has actually been worthy of discipline.

Common Supplier Risks That Lead to Precision Mold Failure

Usual risks within suppliers are usually as a result of the un-noticed gaps in the execution which leads to downstream failures.

Inconsistent Tolerance Execution

Stack-ups are caused by discrepancies in implementing tolerances, which degrades accuracy of multi-cavity tools.

Detecting Tolerance Gaps

Audits with variable CpK values indicated the presence of risks in my sourcing.

Weak Heat Treatment and Material Control

Mistreatment leads to deformity; uneven materials hasten the wear, which is not noticed until a number of cycles are completed.

Material Control Risks

The medical programs did not find any heat lot suppliers who could not be traced to succeed the longevity test.

Poor Assembly and Fitting Practices

Poor assembly brings in defects, increasing wear. These are key precision mold supplier failure risks, often traceable to lax fitting.

Evaluating Long-Term Performance, Not First-Sample Results

Pay attention to long-term performance measures, first samples distort the gradual declines.

Why First Article Approval Is Insufficient

First articles check the accuracy of the static conditions; they do not pay attention to the wear or thermal variations during the run.

Beyond Initial Validation

In my qualifications, there was a demand of accelerated life tests that revealed unmasked weaknesses.

Importance of Wear Behavior and Stability Over Time

Measures wear resistance with simulations or reference; stability provides a stable output.

Wear Evaluation Methods

The mention of the past large-volume projects indicated the actual durability of the suppliers.

How to Assess Lifecycle Reliability

Ask them to provide information about the life of moulds in the same applications; field visit offers verification on the maintenance practices.

Reliability Assessment Tools

My automotive sourcing capability matrices identified lifecycle strengths.

How Precision Mold Manufacturer Selection Affects Production Stability

The choice of suppliers has a direct influence on the stability of production because tooling problems are transferred into the operational problems.

Direct Link Between Tooling Quality and Process Window

Quality tooling enlarges windows, permitting variation; poor quality reduces them, poking defects.

Window Effects on Operations

Electronics had stable suppliers that helped me to cut down adjusting requirements by 40 percent.

Impact on Scrap, Downtime, and Adjustment Frequency

Bad molds mean more scrap due to drifts, time fixing, and tuning.

Quantifying Operational Impacts

In medical lines, scrap doubled poor selections as a risk factor.

Why Supplier Choice Becomes a Production Risk Decision

Selection is risk management, a balance of capability against reliability to prevent chain disruptions precision mold impact on production stability. This is related to precision mold effect on production stability where decisions determine results.

Conclusion — Precision Mold Suppliers Must Be Evaluated as Engineering Partners

A precision mold manufacturer is not to be treated as a vendor, but rather, as an engineering partner, the decisions of which are directly related to the level of stabilization in production and long-term results. Focusing on the capability verification and risk assessment, the OEMs are able to build relationships that reduce surprises and increase reliability. This is an engineering-based strategy, which guarantees the choice that keeps selections in line with operational facts, rather than pledges.