Introduction

Hard anodizing is nowadays one of the most innovative surface treatments of aluminum components, which has transformed the manner in which the industries are reacting towards increasing durability and performance enhancement. This extreme modern electrochemical process creates a very high-strength protective coating that significantly extends the life of the parts while maintaining the lightweight properties of aluminum. Having served in aerospace and other applications where total reliability is mandatory, or in precise medical equipment where biocompatibility is necessary, hard anodizing has become necessary in any product where surface finishing of the necessary rigor cannot be achieved by other methods.

What Is Hard Anodizing?

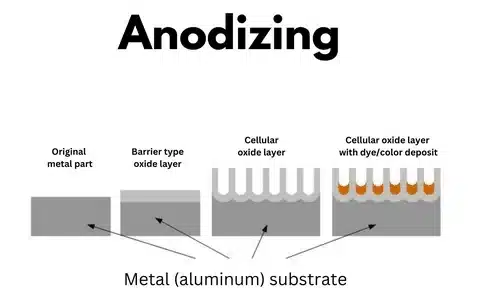

Type III Hard anodizing (also called hard anodizing or Type III anodizing or hard coat anodizing) is an advanced type of electrochemical process that produces a dramatically thicker layer of aluminum oxide than with traditional anodizing processes. Whereas the traditional anodizing process yields oxide layers of between 5-25 micrometers, the hard anodizing process yields a layer between 25-150 micrometers of coating.

This is done by plunging aluminum parts into an electrolytic solution, usually sulfuric acid, but at colder temperatures (usually in the range of 0degC ) and higher current densities than in normal anodizing. Such a controlled environment compels the creation of a crystalline structure of aluminum oxide, which is thick and dense, which advances deep into the material in which it is formed, and at the same time accumulates upon the surface. What emerges is an integrated coating that adheres to the aluminum substrate and not just attaches to it.

Key Benefits of Hard Anodizing

Enhanced Wear Resistance

Hard anodized coating crystal structures are thick and offer superior abrasion resistance, which in many cases is similar or even exceeds the hardness of tool steel. This increases wear hardiness and makes components applicable in high-friction environments in which aluminum would easily wear away. A thick layer of oxide helps to distribute contact stresses over a bigger surface area, thereby minimizing surface wear even in extreme operational circumstances.

Superior Corrosion Protection

Hard anodizing forms a continuous resistant barrier that offers excellent corrosion protection in the most severe environments. The standard thick oxide coating can serve as a sacrificial coating that shields the underlying aluminum against chemical corrosion, salt spray, and atmospheric corrosion. This excellent corrosion resistance increases component life by a long margin, especially in marine, industrial, and outdoor applications where the interaction with corrosive elements is inevitable.

Electrical Insulation

Aluminum oxide coating formed during hard anodizing contains excellent dielectric properties and is suitable for use in electronics projects that need electrical protection. Hard anodized components often have breakdown voltages over 2000 volts, allowing sensitive electronic circuits to be safely housed, with structural integrity and operating thermal constraints.

Improved Thermal Stability

Hard anodized coating preserves its insulating ability at high temperatures, and will often endure continuous exposure at temperatures well above 200 °C without loss. This thermal stability guarantees similar performance in high-temperature operations: engine parts, heat exchangers, and industrial processing equipment.

Hard Anodizing vs. Regular Anodizing

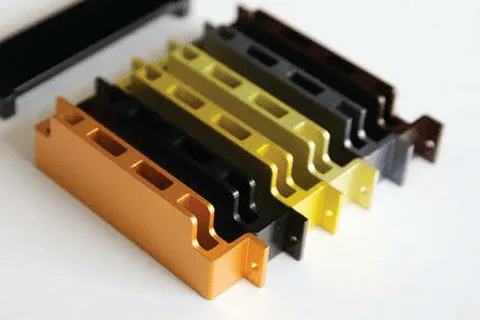

The basic distinction between hard anodizing and regular anodizing is coating thickness and the properties attained. Standard anodizing is a process that yields decorative or light protective finishes of 5-25 micrometers that are normally applied to provide a decorative finish or simple corrosion protection. Conversely, hard anodizing produces a useful coating of 25-150 micrometers intended to be used in hostile engineering environments.

Hard anodized finishes attain hardness values of 300-600 HV (Vickers hardness), whereas normal anodizing is only 150-300 HV. This hardness is directly converted to high wear resistance and life. Hard anodizing also has superior corrosion protection because the barrier layer is much thicker, but this time, it might be darker or attractive than ornamental anodizing.

Process selection varies depending on the requirements of the application: regular anodizing is best used in a decorative application or for mild service conditions, whereas hard anodizing is required in parts that have wear, corrosion, or heat transfer.

Innovative Hard Anodizing Techniques

NUCOCOMP®

NUCOCOMP(r) is a patented innovation of the anodizing technology, which is the fusion of the conventional anodizing and polymer composite fabrication. In this novel process, polymer materials are inserted into the oxide structure as it forms, and a hybrid coating with improved bonding characteristics and greater wear resistance is formed. The polymer bonding minimizes the brittle characteristics of thick oxide layers, with the advantage of preservation of corrosion-resistant and hard characteristics of traditional hard anodizing.

HART-COAT

HART-COAT is a long-standing hard anodizing method that has earned a reputation for being accurate and meeting high standards of quality, including ISO 10074 guidelines. The focus on this process is on the consistency of a coating thickness, even distribution of hardness, and the extraordinary control of dimensional features, which is why it is especially applicable to precision parts whose tight tolerances need to be kept after coating. HART-COAT(r) has been known to be reliable in aerospace and military use in critical applications.

Applications Across Industries

Aerospace

The aerospace industry uses hard anodizing extensively in components where extreme variations in temperature, high-speed air flow, and corrosive conditions in the atmosphere are experienced. The hard anodizing is useful in landing gear components, hydraulic actuators, and structural components because of the improved wear resistance and corrosion resistance that the hard anodizing offers, allowing reliable service over the course of strenuous flight cycles.

Automotive

Due to its increased hardness in anodizing, automotive applications are beginning to use more engine components, transmission parts, and high-performance wheels in their applications. The process makes pistons, cylinder liners, and valve components much more durable, as well as giving the thermal stability required by the modern high-efficiency engines. The performance wheels enjoy the increased wear resistance to the brake dust and the road debris.

Medical Devices

The production of medical devices requires surfaces that are biocompatible and cannot be damaged by body fluids and sterilization procedures. Hard anodizing gives the required corrosion resistance and retains the non-porous smooth surface needed in medical practice. Long-term reliability and patient safety of surgical devices, implantation devices, and diagnostic equipment housings depend on hard anodizing.

Electronics

The hard anodizing offers great electrical insulation properties and thermal management to electronic applications. Hard anodized coatings are applied in heat sinks, electronic enclosures, connector housings, and other cases to offer electrical isolation as well as heat dissipation of delicate components.

Environmental Considerations

Hard anodizing exhibits high environmental benefits over other surface treatments. The process yields products in recyclable forms, such as aluminum hydroxide and aluminum sulfate, which are used in the treatment of water, paper, and the pharmaceutical industries. It is also unlike most other coating processes, which require toxic solvents or yield toxic waste, anodizing works with predominantly water-based solutions and produces little environmental impact.

The sustainability in the longevity offered by hard anodizing also translates to the longevity of component service, minimization of replacement frequency, and minimization of material usage throughout the life cycle of the product. The capability to strip and re-anodize parts also allows a greater benefit to the environment because it allows refurbishment of the components instead of disposing of them.

Conclusion

Hard anodizing is an excellent alternative to aluminum parts that demand superior durability, wear resistance, and corrosion protection in a wide range of industrial, system uses. This is the innovative level of treatment of surfaces that make out of ordinary aluminum high-grade elements that could resist the most adverse conditions of operation and retain the natural lightweight benefit of the material. Having been used in aerospace needs with high reliability as well as in medical precision devices with biocompatibility, hard anodizing is the solution to high-performance features that are demanded by the modern industries. Since manufacturing requirements keep changing to a higher performance and service life, hard anodizing of aluminum surface treatment should be a highly considered option in the industries to gain a better component life, a lower maintenance cost, and an improved operational reliability.