Introduction

Injecting is one of the most common processes of manufacturing plastic parts in large quantities. In the foreground of this process is the runner system on which such factors as production rate, part quality, and costs highly depend. The two basic categories of this type of material are hot runner and cold runner systems, and this paper will attempt to explain why the use of cold runner mold systems is advantageous as well as its limitations and risks in manufacturing industry. This paper seeks to explain the distinction that exists between hot runner and cold runner systems when choosing hot runner systems. while identifying the strengths, weaknesses and ideal uses of the two systems to assist the right decision making on the part of the manufacturers.

Understanding Runner Systems in Injection Molding

Runner systems are the channels of conveying the molten plastic from the injection unit to the mold cavities. Its function is very essential in the proper packing of the plastic injection molding and the uniform exertion of injection pressure and heat in the injection process.. The choice of the runner format and its type expressed the most direct influence on the final result, productivity, consumption and costs of production, especially when comparing hot runner systems .

Basic Components of Runner Systems

It will however be crucial to first explain to the reader some basics of a runner system and how they relate to cold runner counterparts in the context of injection molding. . which is a part of a hot and cold runner system:

- Sprue: The passage through which the material is injected right from the nozzle up to the runner system.

- Runners: These are the channels through which the molten material is directed towards the gate.

- Gates: This is features which allows the runner to interconnect with the part cavity.

- Cold Slug Well: It must be a small well to store the cooled material at the start of the injecting process.

Cold Runner Systems: Traditional and Reliable

Cold runner systems are categorized in injection molding as the conventional approach in the field, being among the first to be developed. They are still in use because of their ease to operate as well as cheap and efficient especially in some specific uses.

How Cold Runner Systems Work

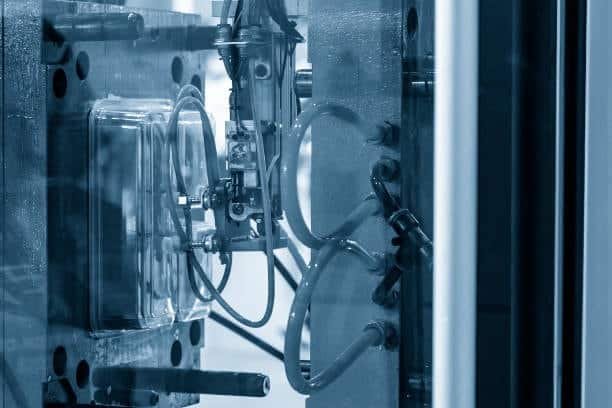

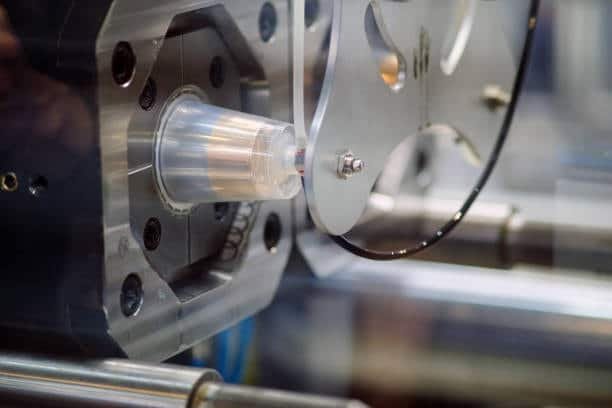

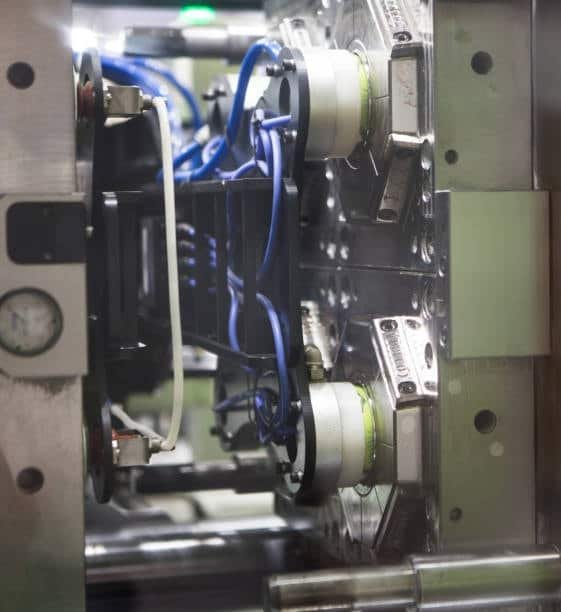

Cold man runner is a method where the entire runner system i:e the sprue, runners as well as gates are integrated on the mold plates through machining, unlike external heating or heated runner systems. . In injection moulding process, the molten plastic is channeled through these fine passages in order to get filled in the respective cavities. Upon injection, the plastic within these channels also solidifies as do the other parts of the injection molded item. When the mold is opened all the parts as well as the runner system are ejected together. The runners need to be stripped off the solidified metal in the cavities which generally occurs by hand or with the help of machines.

Advantages of Cold Runner Systems

Lower Initial Investment

Cold runner molds are less expensive than hot runner systems since it involves less expenses at the initial stages of manufacturing the system. Hot set mold types are cheaper because they do not have heating elements, controllers, or a highly elaborate design; however, they are more costly when the number of units of production is small or medium because the high cost of buying hot runner technologies compared to hot runner vs cold runner options. might not be justified hot runner mold systems.

Simplicity and Ease of Maintenance

Cold runner system can be fabricated easily since it is a single piece system as compared to hot runner system and that means it has less technical knowledge in its maintenance cold runner injection molding. Maintenance problems are usually resolved quite easily and repair can mostly be done at company level without any complex tools or skilled personnel.

Material Versatility

Cold runner systems can handle more materials because they pose no risks to the material due to heat and are more versatile when it comes to the range of temperatures the material can handle. They also perform good with heat sensitive polymers, filled compounds and some of the engineering plastics where hot runner systems face poor melt flow performance manifold system.

Faster Mold Changes

Because the cold runner systems have a more basic structure, they can therefore be very effective for facilities that regularly change products or materials.

Limitations of Cold Runner Systems

Material Waste

This is due to the fact that cured material, which could have been used is thrown away with the cold runner system. The runner system that is formed from the gate, which can actually constitute to 15-40 percent of the total shot weight, has to be stripped off or recirculated for reuse external heat system runner. This wastes materials and impacts the ecological contact of the creation process in manufacturing.

Longer Cycle Times

The cast holistic system is benefits from the difference of cycle time than the hot runner systems because all the runner system have require more time to cool and solidify so that it is easy to remove the parts. This cooling time however adds to the overall cooking time, lead to cycle time hence an added difficulty in production output external heating systems.

Secondary Operations

The necessity of the separation of runners from the parts contributes to extra processing procedures. The removal of runner is time consuming, and need some workforce and some other equipment no matter it is done manually or through mechanical ways multi zone temperature control.

Quality Inconsistencies

Despite the advantages of using cold runner systems, the parts made by this system have more variations in consistent quality compare to produced one using hot runner system especially in the multi-cavity molds as the flow pattern of melt through the cavities is not consistent in both packing and filling processes two plate system.

Hot Runner Systems: Advanced Efficiency

Hot runner systems are considered to be an elaborated technology of injecting molds that was developed to solve numerous problems related to cold runner technology. This is because hot runners hold the plastic in a molten state throughout the runner system, which allows for better injection pressure. and therefore these methods have efficiency, quality and material benefits. Furthermore, Hot runners can reduce material waste but may cause different molding problems if not controlled well

How Hot Runner Systems Work

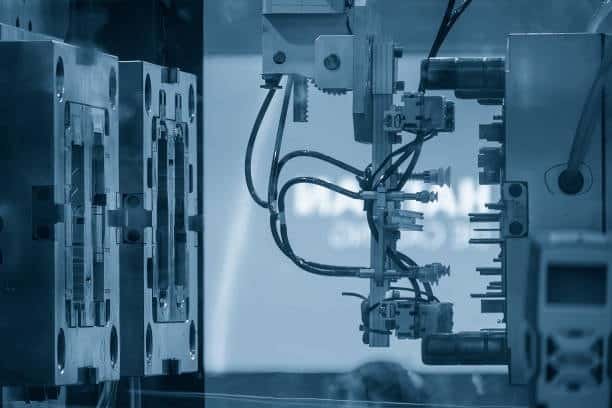

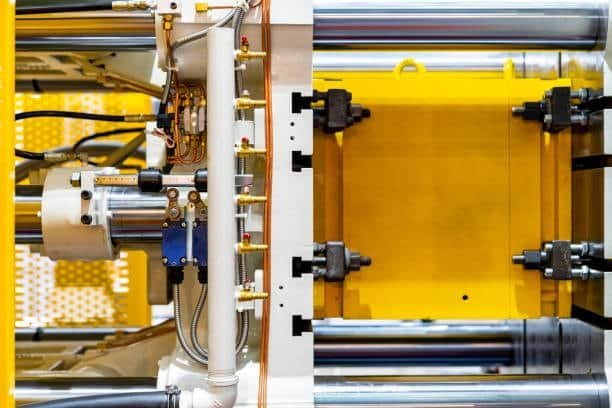

A hot runner system comprises of a number of heated elements that ensure that plastic is kept molten from the injection unit to the gate. Some of the common components of the heated systems are heated manifold, hot drops (also termed as nozzles) and temperature controllers molding cycle. In fact, during the injection cycle, only the resin which goes into the figurine cavity becomes solid while the rest of the plastic confined to the runner system remains molten for the next shot three plate system.

Types of Hot Runner Systems

Externally Heated Systems

These systems incorporate heating units arranged round the runner channel to keep the temperature of the plastic high. They are relatively cheaper to acquire and operate but they offer less accuracy when it comes to temperature regulation.

Internally Heated Systems

The heating elements are arranged in the flow channels to be able to measure and control temperature more effectively though they are usually costlier and harder to implement in designs compared to single tube systems plates heated.

Valve Gate Systems

The following sophisticated hot runner systems are as follows:- Mechanical valve pins which can be used in the operation to control gates and to increase the ability to manage injection process as well as consistency of the part.

Advantages of Hot Runner Systems

Material Efficiency

As for the hot runner systems, there is no waste created by the solidified runners as in the case of the cold system, particularly due to features like spring loaded nozzle tips . The only part formed from the injected plastic is the part, thus the material utilization rate is almost 100 percent in industry leading to reduction of costs in mass production externally heated molds.

Shorter Cycle Times

As the cooler and ejection of runner systems is not necessary in hot runner molds, food performers normally have shorter cycle times. It directly leads to an increased production rate and better use of the machines used in production processes primary difference.

Consistent Part Quality

Hot runner system also give more precise control of temperature and pressure over all cavises, and thus gives better part quality. However, it is important to note that slower cycle times can be a disadvantage if not managed properly.

Reduced Secondary Operations

Since hot runner molds do not have the runner system to be peeled off, the parts require less additional operations manufacturing process. In this case, it is more efficient that there is little or no post-molding processing to be done thus removing the need for extra time, labor carriers or equipment that may further harm the parts.

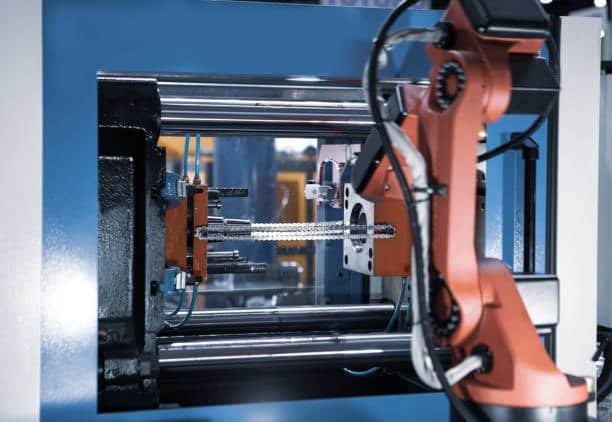

Automation Compatibility

These hot runner systems are more suitable for fully automated production process manufacturing because they can dispense completed parts without any remaining runners for subsequent removal and can be directly integrated with other automated handling systems such as robotic systems.

Limitations of Hot Runner Systems

Higher Initial Investment

Hot runner system often, costs more at the initial stage than cold runner system for manufacturing plastics. System complexity, heating devices, including the air terminal box as well as other regulating and specific elements can augment mold costs by about 15–40 % and even more.

Technical Complexity

Indeed, hot runner systems are highly developed and require professional approaches to design, functioning, as well as service. Temperature should be well regulated to avoid spoiling of the material or failure of the system.

Maintenance Requirements

Some systems of the hot man necessary require a more focused and frequent maintenance. Problems like blocked hot tips, malfunctions of heaters, or those related to temperature regulation make work stop or take more time, increase the general price.

Material Limitations

There are cases when some materials prove sensitive to processing at higher temperatures thus may degrade if exposed to the processing temperatures for a considerable amount of time. This limitation is helpful in the sense that the use of hot runner systems may not be feasible for particular kinds of material.

Comparative Analysis: Hot Runner vs Cold Runner

Production Volume Considerations

Originally, this is a question of whether hot or cold runners are more economic viable, nevertheless, this aspect is highly and greatly influenced by production volume. Although the initial cost of hot runner system is relatively high, this is offset by the cost of material saved and other benefits that comes with it especially in high production volumes.

However, for quantities that are several thousand units per annum or less, cold runner systems are often more cost effective as the initial costs of the system are less than molds and material wasted is considerably low. On the other hand, it can be basically stated that high volume production invariably requires the use of hot runner system where the balance point in general tends to turn out quicker for the parts with large runner or when using expensive material.

Material Selection Impact

Covetrack concludes that the status of heated runner and cold runner systems depends mainly on the specific material undergoing the process.

- Standard Thermoplastics (PP, PE, PS, ABS): Suitable for both systems however hot runner system has certain benefits over cold one

- Engineering Plastics (Nylon, PBT, PC): Hot runner system can be installed but it is important to control the temperature.

- Heat-Sensitive Materials (PVC, some POM grades): are made to run best in cold-runner systems in order to be protected.

- Filled Compounds: may wear hot runner systems, but otherwise works well in cold runners

Environmental Considerations

Since there is growing concern for environmental sciences ejection system, it is about time that people started focusing at runner systems and their sustainability features:

- Material Efficiency: Hot runner systems allow the usage of less material since only the required volume of plastic is injected at one time thus promoting Sustainability.

- Energy Consumption: Hot runner systems require more energy compared to systems that are not designed with hot temperatures.

- Recyclability: As cold runner waste can be reground, it is important to know that this method consumes a certain amount of energy and some properties of the material may be degraded.

Conclusion

The difference between the hot runner and cold runner system is in the essence of the system that manufacturers consider when carrying out injection molding, where the decision made affects the overall performance, quality, and expenses. Cold runner systems are simple to use, cost effective, and can run small and large production volumes depending on the need of the business, but hot runner systems are more efficient in the use of material, provide a better quality product, better flow control, and production is fast as it is suitable for large scale production.

It is important then, due to these that an evaluation is made on the specific needs of the production in terms of volume as well as physical properties of the material; complexity of the part form, quality requirement and cost. Generally, the use of hot runner systems entails a considerably higher initial cost when compared to traditional cold runner systems; however, the payback is realized through significant saving on materials, shorter cycle times, and better part quality especially in high volume production.

As manufacturing becomes more proficient and ecologically responsible recognizing the difference between these runner systems is vital more particularly for the manufacturers who strive to produce high quality injection molded products efficiently and as economically effective as it can be.