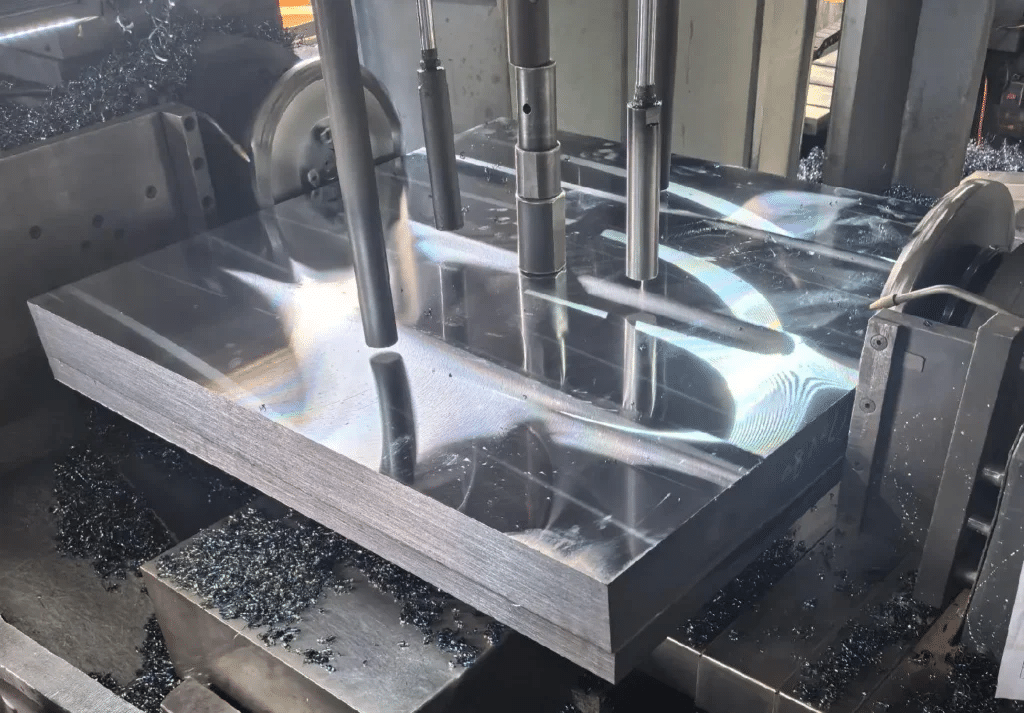

Accuracy in mould production is maintained -or lost over time, mostly depending on the behaviour of steel and on heat treatment, rather than original machining accuracy. Precision loss tends to be time dependent, and is cumulative, as the cycles build up, and reveal structural failures of the material, such as creep or erosion. Dimensional approval at the initial level does not measure the long-term accuracy since approved samples are a representation of the static conditions where multiple heating, cooling, and abrasion processes are ignored. The common belief among a large number of buyers is that once a mold has been machined to some degree of precision, the precision does not change but through heat, load, and wear, the geometry of all molds slowly alters. The quality of heat treatment and the behavior of steel is more relevant in the long-term of the mould accuracy than the machining accuracy of the first sample.

Why Mold Precision Changes Over Time

It is because the precision of molds improves with time as a result of cumulative effects on the operational stresses, so initial accuracy is merely a point of departure.

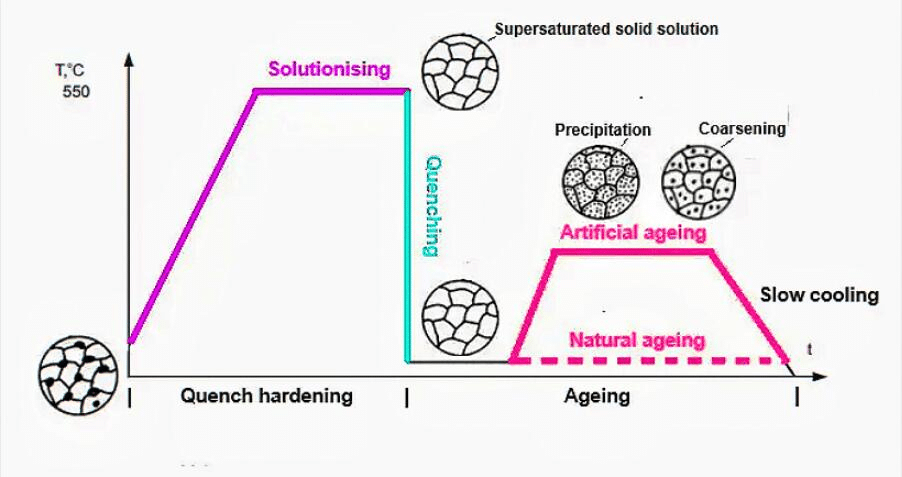

Thermal Cycling Effects

The heating and cooling (to 200-300 o C) (thermal cycling) causes expansion and contraction to cause microstructural changes and, without alleviation, results in gradual warping.

Predicting Cycling-Induced Changes

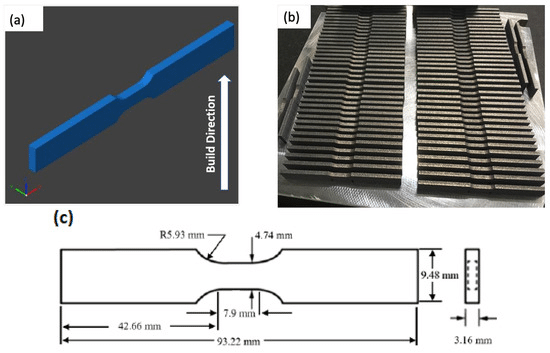

The cycles in the automotive insert molds I have considered reported are in the range of over 500, 000 cycles showing bows of less than 0.02 mm due to unmitigated residual stresses.

Mechanical Stress and Load Repetition

Forces and pressures on the clamp (as high as 200 Mpa) and injection pressures replicate, causing fatigue of the material and increasing cracks or deformation with repetition.

Fatigue Mechanisms in Operation

Repeated loading in high volume electronics tools in my review sped up edge chipping, which ruined accuracy in softer steels.

Wear and Micro-Deformation Mechanisms

The abrasion of surfaces is called wear, micro-deformations such as plastic flow modify features in a subtle manner; neither are unforeseen failures when materials are analysed appropriately.

Mapping Wear Progression

Abrasive resins in medical housings had produced 0.01 mm yearly drifts highlighting the reason accuracy was lost in material-dependent tendencies.

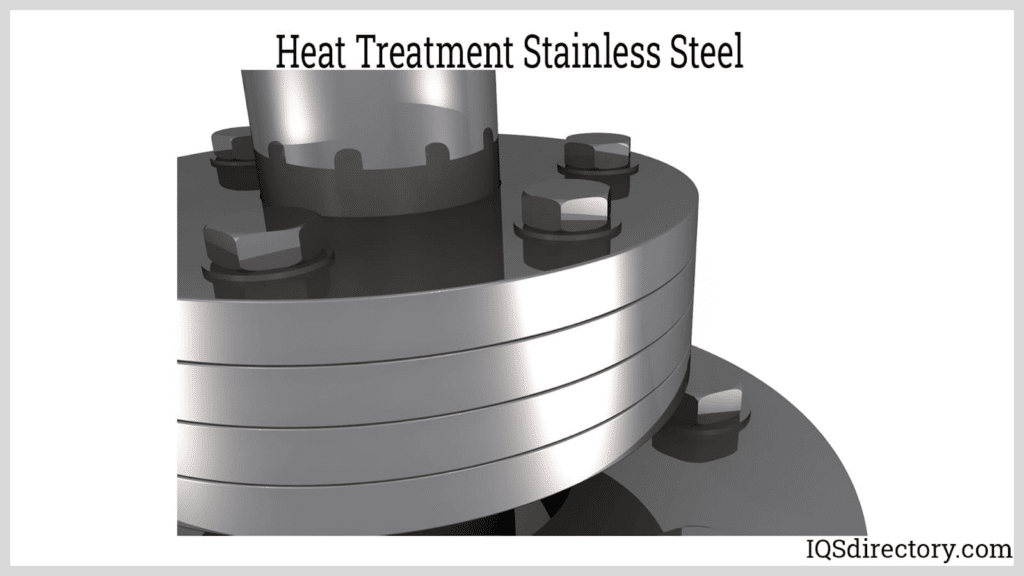

The Role of Mold Steel Selection in Long-Term Precision

The choice of mold steel has a significant implication on long-term precision in that it balances the properties that are not affected by time degradation.

Hardness vs Toughness Trade-Offs

Increase in hardness increases resistance to scratch but lowers toughness and raises the risk of brittle fracture in local impact loads in the long term during usage.

Evaluating Hardness-Toughness Balance

It was found in industrial moulding that the use of balanced steels helped avoid cracking in harder types that occurred after 1 million shots.

Wear Resistance vs Crack Risk

The high-wear resistance steels, such as the ones alloyed with chromium, reduce the erosion but increase the crack propagation where inclusions exist.

Risk Assessment in Selection

My analyses revealed grades that were wear resistant with a life span 30 percent higher, but needed perfect microstructures to prevent premature failures.

Why “Harder” Does Not Always Mean “More Precise” Over Time

Harder steels retain edges longer but tend to change shape during thermal variations, causing loss of precision; less hard, tougher steels tend to retain precision in the cyclic case.

Contextual Steel Choices

In electronics cavities, hardness tradeoffs prevented by tougher steels maintained alignment even though alignment is behavioral, rather than static.

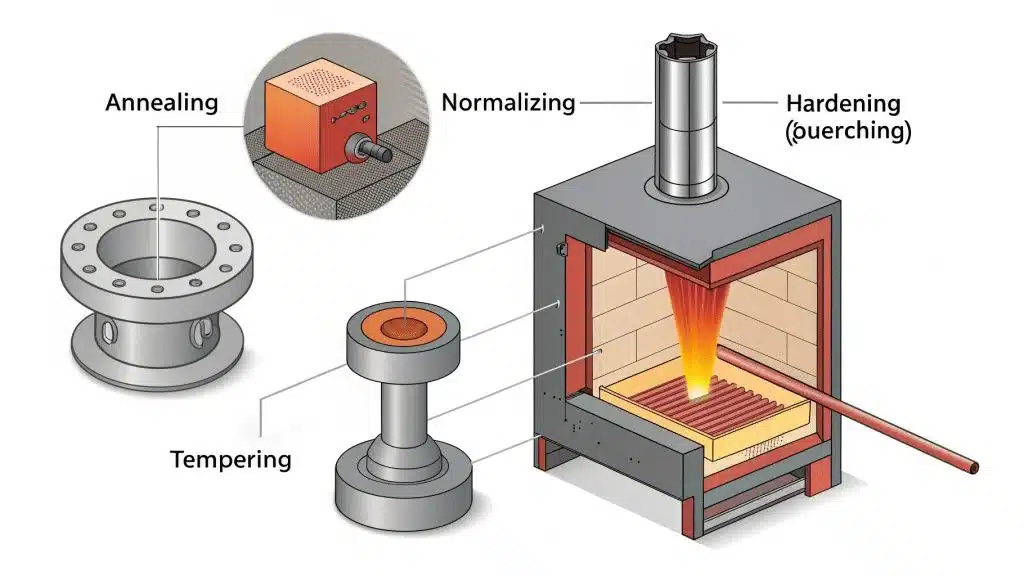

Heat Treatment as a Precision Control Process

Precision is ensured through heat treatment which makes the microstructure stable, although inconsistencies create invisible weak points.

Stress Relief Importance

The annealing of stress reliefs does remove machining-induced tensions, avoiding delayed warping which develops after thousands of cycles.

Implementing Effective Relief

How vacuum annealing helped minimize distortions to less than 0.005mm in my medical tooling projects to prevent long term flatness.

Distortion Risks During Quenching and Tempering

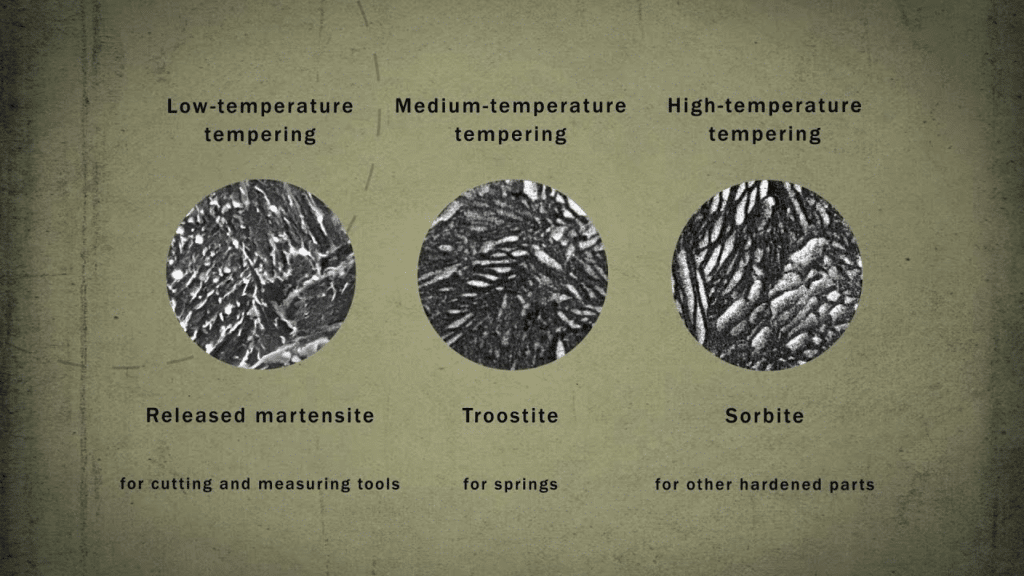

Quenching should not lead to uneven cooling and the formation of martensite resulting in twists; tempering is required immediately after to bring about balanced hardness without softening.

Mitigating Quench Distortions

Controlled oil quenching used in automotive dies minimized the risks compared to water processes which magnified cracks.

Why Inconsistent Heat Treatment Creates Latent Precision Loss

Uneven properties, such as the variable furnace loads, which are caused by batch inconsistencies, cause dispersed wear and latent time-dependent drifts.

Ensuring Treatment Uniformity

The 0.015 mm variances that had afflicted the inconsistent batches were avoiding uniform cycles in high-volume tools that I have controlled.

How Steel and Heat Treatment Influence Wear Patterns

Wear patterns are controlled by steel and heat treatment and have a direct effect on the degradation of precision when abrasive and corrosive environments are present.

Localized Wear vs Uniform Wear

Poor treatment results in localized wear which causes gates to wear more rapidly; the opposite is true of uniform wear which results in wear being evenly distributed.

Patterns in Abrasive Environments

In electronics mouldings made of glass-filled resins, localized under-treated steels, which led to pitting corrosion.

Impact on Cavity Geometry and Alignment

Wear changes the geometry of cavities, rounds holes, or bows walls, and also misaligns cores, all adversely affecting part fits.

Geometry Changes Over Cycles

Audits (won of 300,000 shots) I carried out showed wear-induced 0.03 mm shifts.

How Wear Alters Functional Tolerances

Due to wear, functional tolerances increase, making tight specs loose, which is associated with. steel and heat treatment related mold failures, where material choices precipitate avoidable issues.

Steel Behavior, Heat Treatment, and Dimensional Drift

Dimensional drift which is a minor, yet cumulative accuracy killer, is controlled by the behavior of steel in the heat treatment.

Microstructural Changes Over Time

Microstructures change- carbide precipitation or grain growth through repeated heating- slow change of volume.

Tracking Microstructural Evolution

Tempered martensite tool steels that I have tested have been more stable, that is, they are less likely to drift as compared with bainitic structures.

Thermal Expansion Mismatch

The mismatch of core and cavity steels results in different expansion, which leads to the build up of stresses that are reflected as drift.

Managing Expansion Differences

Medical tools matched coefficients allowed the 0.01 mm annual drifts experienced between pairs to be avoided.

Why Drift Accumulates Gradually

Drift is cumulative with load and is frequently imperceptible until tolerance surpasses limits; it is materially induced, not operational error.

Cumulative Drift Effects

In car courses, drifts were 0.05mm within two years and this is traced back to variation of treatment.

How Material Stability Affects Injection Molding Performance

The stability of the materials used in steel production and treatment decisions are direct factors in the injection molding performance of the life of the mold.

Narrowing Process Windows

The unstable materials reduce the size of windows, and the tighter parameters are needed to mitigate the drifts, which predisposes defects.

Window Contraction in Practice

Unstable steels were used in electronics lines to ensure specs by creating slower cycle times (15%).

Increased Adjustment Frequency

Drifts require frequent corrections such as recalibration of ejections which undermines uptime and stability.

Adjustment Burdens on Operations

My reviews revealed that there was twice the adjustment requirement in molds that were not well treated after six months.

Relationship Between Material-Driven Drift and Production Instability

Variable fill cuts are scraped by the spike of drift induced instability; this underscores the long-term precision impact on molding stability, where materials define reliability.

Steel and Heat Treatment Within Precision Mold Durability Requirements

The crucial decision to determine the lifespan of accuracy revolves around steel and heat treatment that determines the duration of precision in the mold.

Why Material Decisions Define Mold Lifespan

Set lifespan limits Materials set lifespan limits: resistant steels have set limits of millions of cycles, whereas others fail at hundreds of thousands.

Lifespan Forecasting

In the medical validations, the selections increased life expectation twice due to excellent fatigue resistance.

Relationship Between Durability Planning and Precision Retention

Durability planning combines hardness sustenance treatment, which maintains accuracy against fatigue and erosion.

Planning for Sustained Retention

My projects that focused on toughness preserved edges and tolerances were longer.

Importance of Aligning Material Choice with Production Volume

Low-volume is more likely to go with less expensive steels, and high-volume requires high-quality steels in order to be stable.This aligns with precision mold material and durability requirements, emphasizing volume-matched selections.

Conclusion — Precision Is a Time-Based Material Outcome

Machining accuracy alone does not provide the precision of Mold, but rather the choices of material and heat treatment plans that plan ahead the future behavior of the tool throughout many years of manufacture. The lifecycle based thinking will help engineers to avoid inevitable losses by making wise decisions and choices. Such concentration guarantees that molds provide uniform value which reduces risks in harsh conditions.