The design of molds in high-volume injection molding is not only about part-making- what it determines is process stability, efficiency of the process, and the potential risk of production over time. Large volume production multiplies all decisions made in mold design, and the slightest oversights become significant bottlenecks that may completely stop lines or cause defect rates to skyrocket. Problems that may be acceptable at low-volume levels, like small imbalances during cooling or gating, become major dangers at scale and cause an unreliable part, higher scrap, and unscheduled maintenance. Most OEMs believe that a mold that produces good samples would automatically work with mass production, but the high-volume activity reveals latent defects in the design. The effectiveness of high-volume injection molding relies on the mould designs that put stability, durability and repeatability more than short-term cost savings in mind.

Why Mold Design Becomes Critical at High Production Volumes

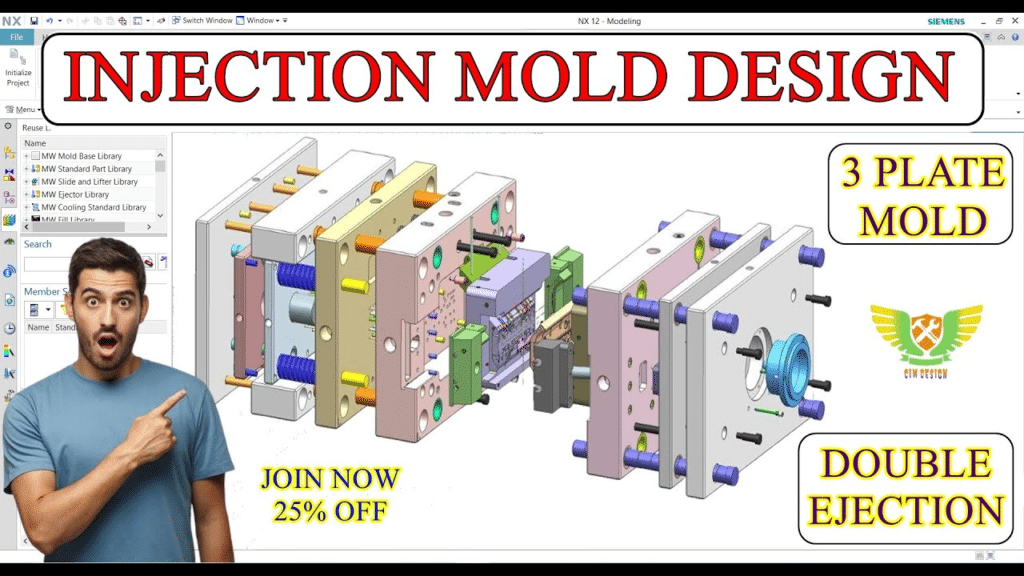

In high-volume situations, the role of design of moulds becomes the most important since it has to resist the incessant repetition without compromising the performance. Single-cavity tools made of aluminum are used in prototype molds, and in injection mold design are multi-cavity (built in blocks of 3 or more), usually of steel, designed to run a few hundred shots before wear causes them to fail; production molds designed with a high volume of injection are engineered to run millions of cycles before failure.

Small design defects are exaggerated by repetition of cycles: a slight imbalance at a gate, leading to no or insignificant variation in low throughputs, may cause a cumulative movement in dimensions or flash during mass production, causing process capability measurements such as Cpk to decrease over time. The correlation between mold design and long-term process capability is direct, whereby well-designed tools have strict control limits and thus the ability to predict and prevent problems with the help of statistical process control (SPC). When switching prototype to production without scaling upscale redesign is usually 20-30% more downtime-intensive, which can be illustrated by my experience that designing injection mold to be used in a mass production does require a proactive strategy.

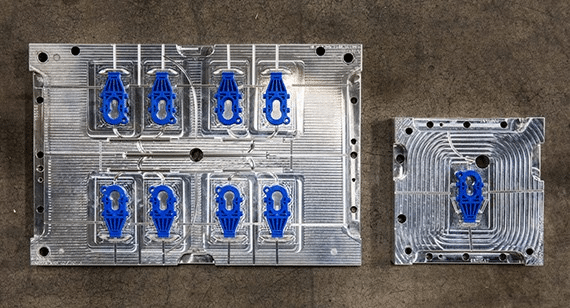

Cavity Design and Dimensional Consistency

Repeatable dimensions in high-volume runs are based on cavity design since even minor irritations can propagate into quality failures. Cavity accuracy is necessary due to the fact that cavity machining needs to be accurate and within a range of tolerance of ±0.005 mm to maintain consistency in wall thicknesses and feature positioning which prevents distortion under pressure.

Symmetry and balanced fill-up cannot be compromised; unbalanced holes result in different fill rates resulting in short shots in some places and overfill in other areas which is seen as the warp or sink marks. This will eventually cause dimensional drift – thermal cycling and resin flow can cause creep that will expand tolerances even further than original specifications.

To achieve production mold design best practices, the best approach to take is to include the process of flow simulations in the early design to identify the hot spots and optimise the layout of the cavity. I have created 32-cavity connectors housing molds in which the balance runners were held at ±0.02 mm accuracy over 5 million cycles. Collaboration with the suppliers of precision injection molding services ensures these designs translate to reliable, high-volume output without constant adjustments.

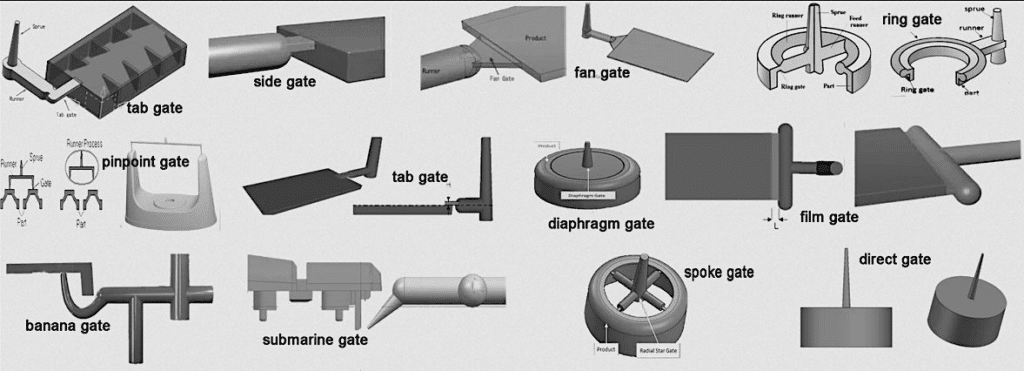

Gating and Runner Design for Stable Cycle Times

Gating and efficient design of runners directly determines the material flow and pressure distribution which is vital in ensuring consistent cycle times in volume production. The location and size of the gate should be in accordance with the geometry of the part, e.g. edge gates are used to clean up flat parts, and pinpoint gates are used to reduce vestige on aesthetics-sensitive surfaces, although an inappropriate size can cause hesitation or jetting.

In runners, balance provides uniform pressure in the cavities; hot manifold heated runners will prevent cold slugs; cycle times will be 10-20% shorter than when using cold runners. Shear heating increase due to poor gating, and thus deteriorate such resin as PC or ABS, resulting in a loss of part quality by yellowing, or brittleness.

In injection mold design with high volume, a reduction of seconds per cycle is achieved by maximization of these factors, and this is multiplied by thousands of additional parts per shift. A well-tuned injection molding process integrates gating seamlessly, as I’ve implemented in electronics enclosures where balanced sub-gates cut flash rework by 40%.

Cooling System Design and Thermal Control

Even distribution of the cooling system design is most important in eliminating the warpage and shortening the cycles since it determines the rate at which the heat is removed in the molten plastic. Curved conformal cooling channels based on part contours are superior to straight line drilled cooling channels, eliminating hotspots, and have up to 30x faster cooling times.

Layout also influences warpage directly – uneven cooling results in residual stressed conditions resulting in bowed or twisted components which do not pass assembly tests. With high volumes, cooling can be the bottleneck; inefficient cooling systems will increase the hold-time, and limit output at a low rate, rather than what the machinery can achieve.

Best practices in production mold design are baffles or bubblers of geometries of complex geometry so that the delta-T across the mold does not exceed 5 C. In my automotive lighting projects, high-tech cooling reduced cycle times by half and maintained a flatness to within +0.1 mm proving that thermal control is the key to sustainable high-volume rates.

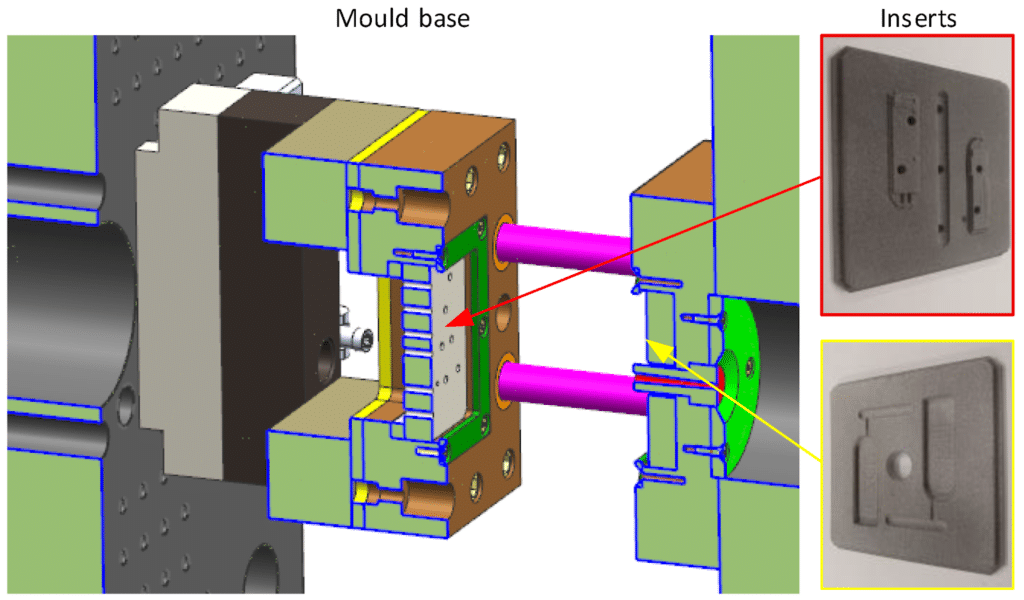

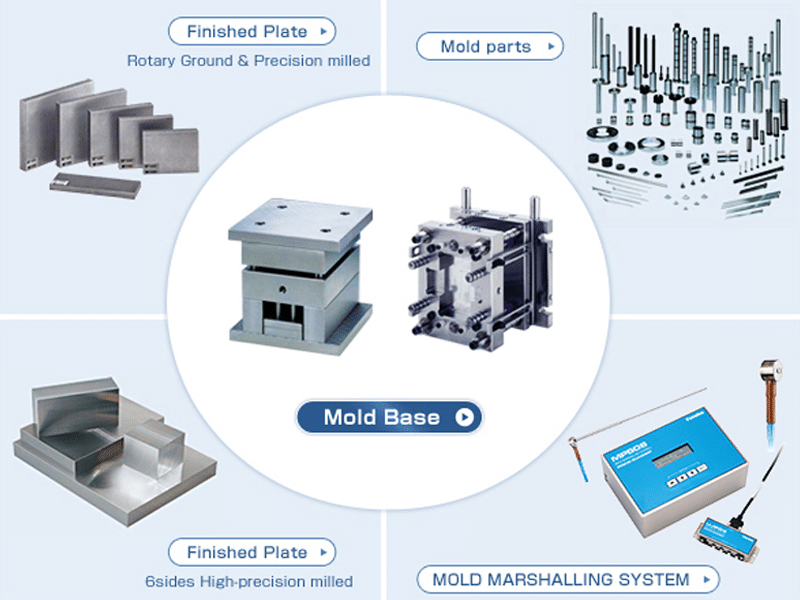

Mold Material, Steel Selection, and Tool Life

The choice of steel has a significant impact on the strength of the mold because the more advanced it is, the more resistant to wear and longer service it is in harsh conditions. A mix of toughness and machinability is available in P20 or H13 steels that are used in general, and premium grades such as 1.2344 ESR offer better thermal fatigue properties to abrasive resins.

Glass-filled wear or PVC off-gassing corrosion will reduce life unless prevented by applying protective coating such as TiN or CrN, although ultimate life depends on the quality of base steel. Maintaining factors, including available inserts reduce downtime, I have witnessed molds deteriorate due to neglected erosion losses weeks of repair.

With volume manufacturing and injection tooling, tool life is more important than initial cost – a 2m cycle mold is worth the more expensive steels as opposed to a 500,000 cycle mold. Understanding why mold quality matters in injection molding highlights how material choices secure long-term viability.

Tolerance Planning in High-Volume Mold Design

Tolerance planning should distinguish between nominal and functional specs to take into account the unavoidable wear in long-runs. Nominal tolerances are made consistent in all dimensions, whereas functional ones are aimed at important characteristics such as mating interfaces, where strict bands are necessary to facilitate production.

Precision is eroded over time due to wear of the moulds – abrasion on the cores can open holes by 0.05 mm in 1 million cycles, forcing parts out of spec when unexpected. Defining datums and controls is a priority of GD&T that makes sure that areas of interest are stable.

In the case of high-volume injection mold design, this will entail compensation, such as adjustable inserts. In medical device tooling that I have been in charge of, I have been functional. tolerances in injection molded plastic parts maintained assembly fit despite wear, avoiding mid-run modifications.

Designing for Maintainability and Process Stability

Designing molds that are maintainable also helps to minimize unplanned stops, as it helps to repair and modify them easily. Such characteristics as modular inserts and quick-change systems enable one to switch components without disassembly, reducing the downtime by hours down to minutes.

The design ethos contributes to the stability of processes – frequent access to cleaning eliminates the accumulation leading to flash or burns. The gap between design intent and reality is closed by feedback loops in which production data informs changes made such as vent resizing.

Practically, maintainable designs have prolonged by 25% the run times in my high-volume undertakings, placing an emphasis on prevention expressed through friendly layouts, as opposed to corrective actions.

Conclusion — High-Volume Production Exposes Mold Design Reality

In high volume injection molding, the decisions in mold design are put to test thousands of times per day, and durability, consistency and maintainability are the real parameters of success. The avoidance of these in favor of first savings prevents the traps of re-working, scrap and line stoppage which mar manufactured tools. Consistency over time comes through careful consideration of cavity balance, cooling efficiency and material strength and it promises molds work consistently during the demands of mass production. The engineers should be able to see design as a commitment to continued production where long-term thinking is more important than cost-reduction in achieving long-term consequences.