Comparing injection molding with CNC machining of precision plastic parts, neither process is always better than the other but factors such as volume required, tolerance repeatability of required and cost of the entire lifecycle can usually be tipped to favor molding, especially when high volumes are required. CNC machining is flexible when the run volume is low or the design is iterative, however as volume increases the capacity of injection molding to yield constant geometries under a constant tool is the more predictable choice. Numerous OEMs believe that CNC machining is always more accurate and, in practice, injection molding can be capable of providing better dimensional consistency when equipment and processes are stabilized. Both injection molding and CNC machining are precision-capable operations, but their application is based on radically different manufacturing goals based on volume, tolerance stability, and long-term production requirements. In the case of precision plastic components, CNC processing is preferred over injection molding due to being flexible and low-volume, whereas injection molding is the more dependable method to use when it comes to repetition, stability, and scalability of accuracy in manufacturing. Being a manufacturing engineer, and having over the years, assessed these processes with regard to automotive and electronics OEMs, I have witnessed how a lack of understanding the trade-offs of these processes results in suboptimal decisions made: rushed CNC prototypes with no scalability or insufficiently tuned molds that fail in production.

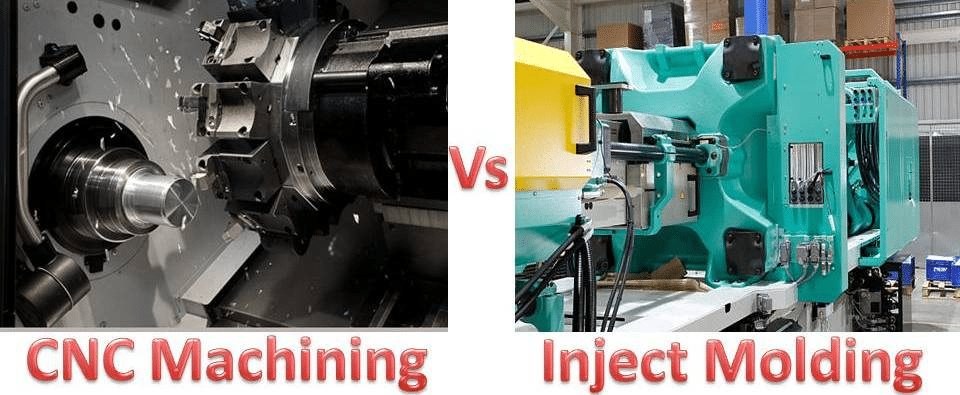

Fundamental Differences Between Injection Molding and CNC Machining

Injection molding and CNC machining are the opposite of each other in the technologies of producing plastic parts: formative and subtractive, with the former adding the shape by flowing the material and the latter cutting the solid one. Subtractive CNC machining builds up features by subtracting the material in layers, providing control over discrete features, but exposing parts to tool forces that may cause stability problems. Formative injection molding pressure fills in a hollow with melted plastic that hardens under pressure to even density but depends on the shape of the mold for precision.

CNC one-part-at-a-time accuracy is appropriate to custom adjustments, whereas repeatability in molding is cycle based to provide the same output in thousands of shots. Precision is different: CNC gets in such a place once, whereas molding keeps it together, depending on shrinkage and solidification. This difference is usually a shock to teams in process audits that I have carried out, CNC wins prototyping with its versatility, and the consistency of molding production.

When CNC Machining Is the Better Choice for Plastic Parts

CNC machining becomes the preferable option in plastic components when consistency in the volumes is not important and the design capability is more significant than the demand in mass standardization. In the first generation with CNC, geometry can be quickly changed without the expense of tooling mill a new mark or change dimensions on-software, which is useful in assemblies such as electronic houses where it is important to test the fit. This is appropriate when the run quantity is less than 100, and it does not pay to invest in molds, and local tolerances of -0.02 mm on the key holes can be obtained without cycle dependencies.

But it is not blanket, CNC is good on thermoplastics such as ABS or polycarbonate when doing functional tests, but thermal effects during cutting may cause warpage in thin areas. Based on engineering analysis, I have recommended to OEMs that CNC be employed in this case to provide speed, although that should be switched over sooner than later, as volumes increase and that prevents overreliance which in turn restricts the efficiency.

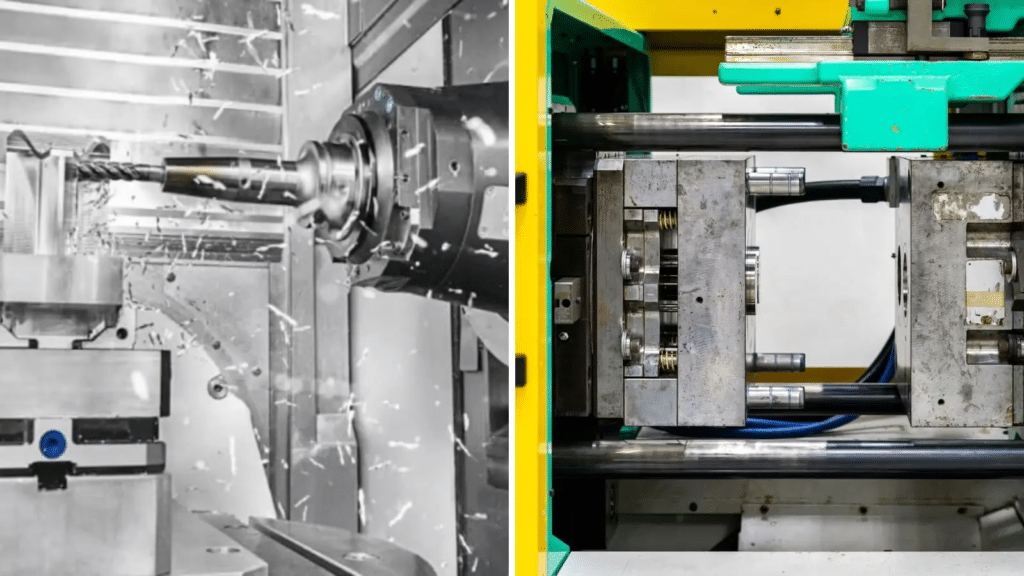

Why Injection Molding Excels in Repeatable Precision

Repeatability Injection molding is highly repeatable since it is based on mold-defined geometry, and can generate the same parts on a cycle, unlike CNC which is based on one-off in high volumes. After tuning the mold, every shot is precisely a replica of the cavity, including such tolerances as ±0.05 mm across walls, without recalibration, which is important when multiple cavities are involved in the tool. Here the concept of process stability is true to shine: there is control of melt temperatures and pressures, which results in low differences, and the parts maintain shape during loads during operation.

This repeatability is clear in production runs of 1,000 or more whereby CNC manual setups bring about drift. Scalable solutions are sought after by those, precision injection molding services integrate tooling expertise to lock in this advantage, delivering uniform outcomes that CNC struggles to match at scale.

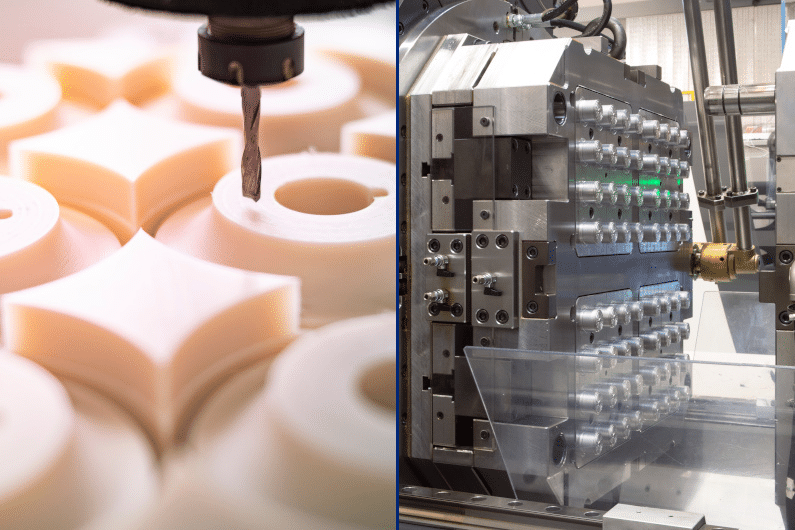

Tolerances — Accuracy vs Consistency in Plastic Manufacturing

Plastic tolerances indicate the difference between CNC precision in single features and IM precision in volume where nominal tolerances have to meet operational requirements or overkill will occur. Nominal tolerance is what is stated such as a range of ±0.1 mm but functional tolerance is based on real life application such as how a part mates or flexes at a load. CNC is a tight accuracy that is made by the precision of the paths and machinability of plastic introduces chips or heat, which impacts edges and causes batch inconsistencies.

Instead, injection molding sustains tolerances by repeatedly by using the mold, but the shrinkage (0.5-2%) must be compensated in design. There is no guarantee that it is always possible to do things tighter, and the temptation to stretch the material limits is an invitation to failure. Insights from tolerances in injection molded plastic parts clarify how molding’s predictability often trumps CNC’s spot precision.

Quality Risks and Process Control Differences

The types of quality risks vary significantly: CNC machining may encounter variability due to worn tools, or a changed setup, the potential shift in the dimensions during a single run is 0.02 mm; injection molding may experience warpage, sink marks, or short shots caused by the uneven cooling process or gating. The risks associated with CNC are batch-specific (vibration may burr edges, and deburring is necessary), but can be managed by the attentiveness of the operator. Molding: are process global: the clamp force cannot be constant and requires strong control measures such as sensor controlled cycles.

The control in the process is important- CNC depends on the rigor in programming, the maintenance of the mould on the maintenance of the moulding. Both require discipline in the demand, and the magnitude of molding exaggerates lapses. To prevent it, it is important to investigate.common quality issues in injection molding reveals how targeted controls mitigate these.

Mold Design as the Deciding Factor in High-Volume Precision

High-volume precision in injection molding is eventually determined by mold design, with cavity planning, gating and venting determining uniformity of parts to a location way beyond the ability of CNC to replicate on a large scale. Even fill with no hot spots and quality tooling made of hard steels prevents defects such as voids, poor designs create knit lines or uneven shrinkage and one loses accuracy after cycling. Gating placement influences balance of the flow which is crucial in consistency of the multi-cavity and venting removes trapped air that initiates burns.

The equation changes with tooling investment: initial costs will give it per-part savings in thousands. Based on design consultations, I have emphasized this pivot. Details in injection mold design for high-volume production underscore its role in precision.

Material Behavior in CNC Machining vs Injection Molding

The behavior of materials differs between the processes: CNC machining verifies machinability where plastics such as nylon machine away well although it heats and thus bends thin walls, and injection molding insists on good flow to fill cavities without bubbles. CNC stress relief Stress relief in CNC is an after-cut annealing to reduce residual stresses, and molding creates stresses in the mold that are molded-in during rapid cooling, leading to bowing unless fully gated.

Selection of material changes appropriateness – high flow resins are ideal in molding intricate design, and machinable grades are more appropriate in CNC machines to develop prototypes. This informs decisions; referencing choosing the right plastic for injection molding helps match behaviors to needs.

Why Mold Quality Ultimately Determines Injection Molding Precision

The precision of injection molding is fundamentally dependent on the quality of the mould as the integrity of the tool steel, the precision of the machining and the maintenance of these tools control the ability to maintain dimensional stability when running long the tool life. Steels of high grade are not affected by abrasive resin, so the cavity detail remains, and the machining is made precise, so the walls are uniform, but poorly made tools cannot hold the pressure, and their tolerance can change by 0.1 mm, and results are not consistent releases. Molds like these build up and require cleaning, which involves polishing, whereas poorly maintained molds accumulate residues and the tolerance will vary by 0.1 mm.

This attribute maintains accuracy: consistent molds measure in the range of -0.05 mm in 100,000 shots. In assessments, I have associated longevity with this. Exploring why mold quality matters in injection molding emphasizes its foundational role.

How OEMs Should Choose Between CNC Machining and Injection Molding

OEMs ought to consider volume – below 500 units is preferable to CNC due to low tool cost, and above to molding due to part cost efficiency. Evaluate design maturity: fluid prototyping is compatible with CNC prototyping, locked designs capitalize on the repetition of molding. Lifecycle cost has risks CNC flexibility has the tradeoff of high unit prices in small runs, whereas molding up front investment pays off at scale with amortization buffers.

Transition strategies incorporate CNC on proofs then molding on production guaranteeing tolerance transfers.

Conclusion — Precision Depends on Production Intent, Not the Process Name

To conclude, injection molding and CNC machining can be accurate to plastic components, but their advantages are oriented towards purpose, namely, scalability and flexibility respectively. The focus on being able to repeat items rather than doing a single act helps in making decisions to achieve sustainability. The superior process is not determined by precision assertions, but the dependability of that precision continuing through the manufacturing existence of the product- it is the utilitarian prism of engineering victories.