Low volume machining involves part production in limited quantities, with order quantities running from several dozens to several thousands of units, whereas injection molding is often used for larger batche . Unlike methods of mass production, low volume machining succeeds well in prototyping, manufacturing limited quantities, or attending to the needs of specialized components, making it ideal for short runs . The low volume machining allows for the convergence of the high accuracy and versatility of machining with the effective production of small runs by providing an effective solution.

This article elaborates on the critical factors and vital aspects of low volume machining, including precision manufacturing techniques, materials used, advantages and applications, scale production, and reasons why it is becoming popular in a wide range of sectors.

What is Low Volume Machining?

Low volume machining is the manufacturing of parts or components in limited quantities. Advanced machining procedures, including cnc machining capabilities and various cnc machines, are employed, such as CNC machining, precise milling, turning, and laser cutting. to obtain tightly controlled components that ensure precision and accuracy. This technique is commonly used to produce custom parts, complex parts a prototype, or even a limited production run for aerospace, automotive, medical products, and electronic purposes.

The low volume category usually entails producing low volume production runs of less than 10,000 units, very different from high-volume operations, which v-aligate mass production of dozens if not hundreds of thousands of units. While manufacturing in small quantities, low volume machining focuses on the delivery of precise, high-quality components and flexibility, making it ideal for short run production .

Key Processes in Low Volume Machining

A number of vital machining capabilities are applied in low volume production; this, in turn, assists manufacturers to produce high quality components in a short time with minimal setup, highlighting the benefits of low volume . These processes include:

1. CNC Milling

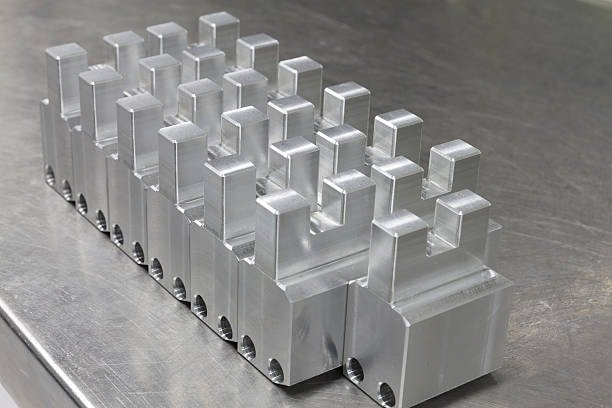

This machining procedure known as CNC milling, uses rotating cutters to shape a workpiece by removing the unwanted material. Its ability to work well with cnc machines, geometric and detailed features makes it a good candidate for low volume production, fulfilling various cnc machining needs . The CNC mills can handle a variety of materials from metals to plastics and composites, giving the manufacturers flexibility both in design and material used.

Low volume operations especially can benefit from CNC milling due to fast-up lead times, low setup costs, and capabilities of changing the designs of parts on the spot.

2. CNC Turning

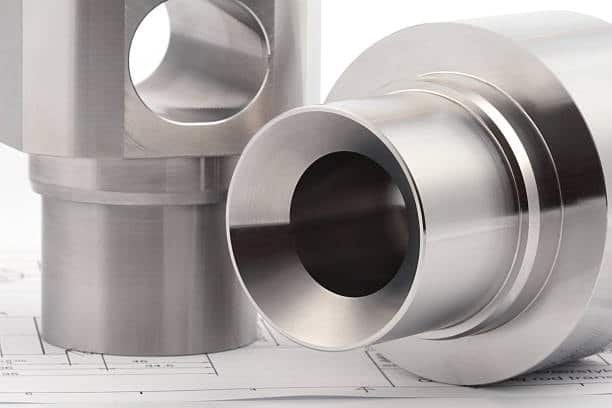

CNC turning is a critical technique in the production of parts in small volumes. The process is that of a fixed cutting tool modelling eating a rotating workpiece to produce cylindrical shapes and specifications. With the help of CNC turning, manufacturers can produce shafts, pins, and bushings with the remarkable level of perfectionity.

Combination of CNC turning and high end CNC machinery produces parts with tight tolerances and appropriate for functional use finishes, including those that require complex geometries . It is also found routinely in industries wanting exacting standards and can manufacture parts that are uniform.

3. Laser Cutting

Laser cutting uses strong beams of shining light in order to form extra precise cuts or engravings on materials. In case of generating intricate cuts and features in thin sheets of metal or plastic, there is nothing that compares with the precision and noncontact operation of the laser cutting, especially in response to market demand . For manufacturing unique parts, prototypes, or small series that require tight tolerances, laser cutting is common in low volume machining operations, particularly in various prototyping projects.

The advantages of laser cutting are enormous; it has the ability to present clean cut edges and achieve the highest quality , eliminate waste, and work to allow rapid design modifications without the need to use different tools.

4. EDM (Electrical Discharge Machining)

This new process known as Electrical Discharge Machining disintegrates material through electric discharge impulse between an electrode and a work piece. EDM is specially able to work on hard material and produce intricate, detailed parts. EDM is often used for low volume production when complex parts are needed with extra accurate dimensions and rigorous quality control to ensure a class quality surface finish, avoiding the need for expensive tooling .

Materials Used in Low Volume Machining

Material selection plays a big role in low volume machining operation results, which is essential to produce high quality parts . Low volume machining often involves metals, plastics, and composites in smaller quantities , with differences in benefits when applied depending on the needs of applications.

1. Metals

Low volume machining tends to promote metals for their durability, strength, and reliable performance in demanding applications. Some commonly used metals include:

- Aluminum: The combination of being lightweight, corrosion resistant and easily machined also makes aluminum a material of choice for low volume manufacturing in aerospace, automotive and consumer electronics industries.

- Stainless Steel: For it’s outstanding corrosion resistance and strength, stainless steel is widely used for manufacturing medical devices, cars parts, and industrial parts.

- Titanium: Titanium is preferred for aerospace, and in medicine because of superior strength, reduced weight and the ability to safely integrate with the body.

2. Plastics

Premarkarily, plastics are prized primarily as a result of their cutability, light weight, and durability against chemical exposure. These plastics are used in producing many low volume machined components:

- Delrin (Acetal): Delrin is appreciated for its superior mechanical properties and low friction properties which make it a common material for gears, bearings, and automotive parts.

- Nylon: A durable rugged plastic, resistant to wear that finds widespread use in automotive and industrial components.

- Polycarbonate: The material’s transparency, strength, and hardness against impacts contributes to its widespread application in items such as medial devices and electronic parts.

3. Composites

Carbon fiber and fiberglass like composites are catching up in low volume machining due to impressive strength- weight ratios. In industries such as automotive and sports equipment, aircraft where parts must be strong and light, composites are valued for their performance.

Advantages of Low Volume Machining

Low volume machining has some distinct benefits to firms that want to manufacture customized parts or the prototype of a component for medical industries compared to the traditional high volume manufacturing technology, especially in terms of cost tooling .

1. Cost-Effectiveness for Small Batches

Low volume machining is unique because of its financial efficiency when it comes to small production runs. Low volume machining distinguishes itself from classical mass production as it eliminates the customers from the high costs involved to manufacture molds and tools, but allows flexible and cost-friendly production, ultimately influencing the final product . This method will be particularly useful for startups/disruptors, small business, or product developers who need premium quality parts without the need for expensive mass-production investments.

2. Quick Prototyping

Low volume machining does very well in terms of rapid prototyping. Designers and engineers can test how their parts will look and perform before a large scale manufacturing investment through the fast production of prototypes, which is ideal for prototyping . This rapid production cycle reduces development cost and cuts down on timelines hence a faster entry into the market, contributing to reduced time in the overall production process .

3. Customization and Flexibility

Low volume machining offers designers a very flexible approach to the design of parts. Design modifications can be introduced in different stages of the manufacturing process so that businesses can easily accommodate the changes in customers demands or requirements. Using this capabilities flexibility, businesses can manufacture unique or niche components that accurately cater to the needs of specific applications, ensuring a quick turnaround .

4. High Precision and Quality

In small batches, low volume machining can actually produce parts with high accuracy and with very good surface finishes. The use of state of the art techniques including CNC milling and turning ensures that parts with complex shapes and specifications are built which could be used in different machined parts critical institutions and by low volume production companies, namely, medical devices, aerospace and automobiles.

Applications of Low Volume Machining

Several areas enjoy low volume machining where attention is paid to the rigid requirements of exact and limited production orders. Some key applications include:

1. Prototyping and Product Development

Low volume machining process is essential for prototyping, scale production, and product development advancement. It is this process by which engineers and designers can create prototypes, and alter designs efficiently before moving to high volume production.

2. Aerospace and Automotive

In aerospace and automotive industries, low volume machining is essential to manufacturing engine parts, brackets, and housings in the most precise way that these industries require.

3. Medical Devices

The medical device industry finds high demand in low volume machining, used to produce detailed small parts such as surgical instruments, implants and diagnostic machines that all have to meet stringent standards of quality, similar to those in automotive aerospace .

4. Consumer Electronics

For consumer electronics, low volume machining is an important material removal approach used to manufacture critical components like connectors, housings, and internal parts that call for high precision and customization in order to achieve the product performance and shape.

Conclusion

Small-scale manufacturers can get flexibility and precision while also considering the reduced costs with low volume machining capabilities. By using updated approaches such as CNC milling, turning, and laser cutting; the makers can offer customized components to businesses such as aerospace, automotive, medical, and electronics firms.

Such an approach is excellent for prototyping, for developing special parts or small batch production to allow companies to quickly develop and verify their designs at much lower cost and without the typical delays of mass production.