Machining design is an integral component of the contemporary manufacturing process because it includes detailed plans and specifications in manufacturing components and parts from raw material through cnc machining processes. The shape (design) of a piece or product has a significant effect on the efficiency cost and quality of the machining process. A well-planned machining design guarantees that the part can be fabricated correctly, swift and on time.

Also, considerate machining design considers issues such as material, tolerances, surface finish, and access to tools, operations sequence and so forth, which impact manufacturability and application of the final product in the design for cnc machining . Through optimization of the aforementioned factors at the design stage, manufacturers could cut down the production time, tool wear, and errors or rework which would otherwise be costly. Effective machining design is not just a way of simplifying the fabrication but an assurance of fulfilling performance requirements while getting production economical and scalable, a backbone of successful modern manufacturing.

This article tackles the significance of machining design, including the drill axis the determinants that make its success to certain degree, the process of designing for manufacturing including technical drawings and the effect design decisions have on production cost and time-frame.

What is Machining Design?

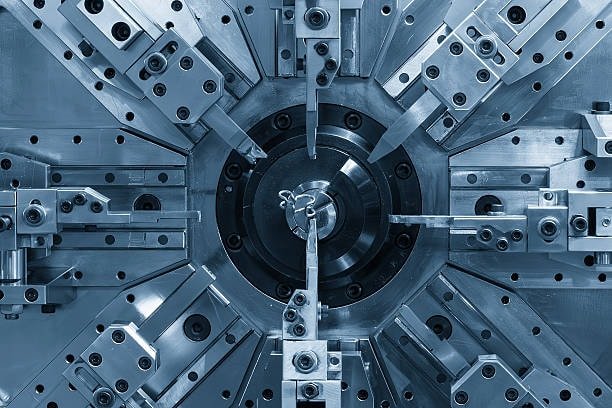

Machining design is designing parts or components with application of machining in mind and which when machined to form a final product they can easily respond to machining methods such as turning, milling, drilling, grinding, and other subtractive manufacturing processes. The objective of machining design is to produce a part that satisfies all functional requirements regarding tool geometry and needs to be machinable at the lowest possible cost and at the minimum periods of production.

To this end, the use of machining design makes it simple and avoids superfluous complexity in shapes or features that would need special tooling or excessive machining needs. Designers most times try to standardize dimensions, use readily machinable materials as well as have features that conform to typical machining practices in order to keep it both easy and inexpensive. Apart from that, a good machining design also takes such considerations into account as clamping, internal corner radius, and fixturing in manufacturing process so that the part can be gotten hold of as well as easily obtained during the machining. Through fusion of the functionality with manufacturability, the machining design provides a determinative role in driving efficiency, guaranteeing quality and facilitating mass production without compromising the performance.

Machining design necessitates a detailed knowledge of machining processes, materials, tooling and machinery potentials. Designers have to take into account such factors as part geometry, tolerances, material properties, boring tools ease of fixturing and tooling in order to achieve the best results.

Key Factors in Machining Design

Several important considerations such as drilled holes must come up when designing for machining in order to achieve maximum production results. Such factors are, part geometry, material selection, tolerances, threaded holes surface finish requirements, and machining processes to be used among others.

1. Part Geometry

Among the most critical factors in machining design is the geometry of the part. The complexity of the shape of the four cylinder cooling unit will influence the choice of different machining processes, the number of setups required, drill axis perpendicular, and ease of manufacturing. Geometrical complexities or detailed features may have special fixtures or a part process which can include multi-axis machining or after machining or other operations.

Part geometry has a direct effect not only on machining strategy but rather overall production schedule and cost. The complicated shapes with intricate shapes usually require advanced machining procedures such as the 5-axis milling or specific tooling to achieve the desired accuracy. This can add up the setups and cycle time; more over some sharp corners and post-machining operations such as deburring of surface finishing may be necessary when using cnc cutting tools . On the other hand, less complex geometries are easier to machine, with fewer setups, easier fixturing, and hence overall more efficient productivity. Hence, the consideration of part geometry made during the design stage can balance functionality with manufacturability resulting in more efficient and time effective production which is cost effective.

Design Tip:

Design rather uncomplicated, but completely symmetrical parts that can be easily fixtured during the machining process thus removing the necessity to avoid sharp internal corners and complicated tooling arrangements and thus wining time during the machining operation.

2. Material Selection

The choice of material is of high importance in the machining design because different materials are machinable in different ways. For example, the aluminum, which is softer, is easy to machine, but titanium or high strength alloys will require special tools, and machining procedure. Properties of a material such as wall thickness, hardness, ductility, drill bit and thermal conductivity must be considered properly so that machining is effective and the part performs best.

Not only is a choice of material for machining connected with the ease of fabrication but also with different wear of tools, machining velocities, and the quality of finishing. Hard or tough materials such as titanium or hardened steels typically require lower cutting speeds, stronger tooling and even special cooling techniques to prevent breaking off of the tools and to maintain the dimensions. On the other hand, slightly softer materials such provide for limited cutting length, faster machining and longer tool life but push the envelope on such things as chip control or surface finish uniformity. Also, it is important to understand tool diameter thermal conductivity since the materials that are effective in dispersing heat minimise thermal distortion during machining. Through precise alignment of material properties and machining abilities, designers and manufacturers are able to achieve maximum efficiency on the production floor and maximum functional performance on the finished part.

Design Tip:

Materials to choose include those that do not skew against machinability but are strong enough for the design requirements and the design of the part must suit the machining capabilities including specialty tools .

3. Tolerances and Fit

Tolerances are the amounts of dimensional variation permissible for a part. Tight tolerances are frequently required in the manufacture of those parts which have to fit together exactly, such as mechanical assemblies and electronic parts. It is, however, possible to have very tight tolerances, including circular path, and this has a tendency of increasing the machining time and costs. It is therefore imperative to define tolerances that are justifiable in terms of function and application of part.

Determination of machining design tolerances at appropriate levels is a very subtle balancing act between the cost of manufacturing and the functionality of the part. Unnecessarily tight tolerances require slow speeds of machining, regular quality checks, and even additional processes of finishing, which increase time and money spent on production. On the other hand, in the case of tolerances which are too loose, this may cause poor fit, low performance/performance loss, or issues of assembly. By examining the details of the individual part and its function as part of the finished product, the designers can provide accurate tolerances while considering tool deflection that retain precision without overburdening the part’s design. Such considerate approach supports managing the machining process effectively, and parts stipulated in terms of quality are produced without compromising efficiency and costs.

Design Tip:

Indicate tolerances only under absolutely necessary circumstances. Beware of tight tolerances that tend to make the process of manufacturing in machine shops complex and expensive.

4. Surface Finish Requirements

Surface finish is a major design consideration in the majority of machining parts, particularly when there will be a lot of wear, friction, or aesthetic requirement. Depending on the different machining process but, some blind holes can produce different surface finishes, different machining processes can produce different surface finishes, some with rougher finishes that may need polished or ground to a higher quality where little or no post-processing would be required. The definition of surface finish requirements has to be defined during design.

Surface finish has a direct influence on the performance as well as the outlook of machined parts and therefore is a significant consideration during the design phase. Rough finished surfaces will lead to increased friction and wear and even failure in moving or contacting constituents while smoother finishes will increase durability and requirements for lubricants. Some machining operations like grinding or fine milling are inherently capable of producing finer finish but they may increase time taken in production and cost of production. On the other hand, there might be operations such as the rough turning or drilling which might give surfaces calling for further finishing treatments. With defined requirements for surface finish in the design stage, manufacturers will be able to apply the best machining techniques and avoid expensive post-processing thus allowing the parts to satisfy functional as well as aesthetic standard quickly.

Design Tip:

Balance this need for a flow of smooth surface finish with production ability. For example, if a part needs a high quality finish, ask yourself if it can theoretically be produced in the current machining process or if some additional operations will be needed.

5. Machining Processes

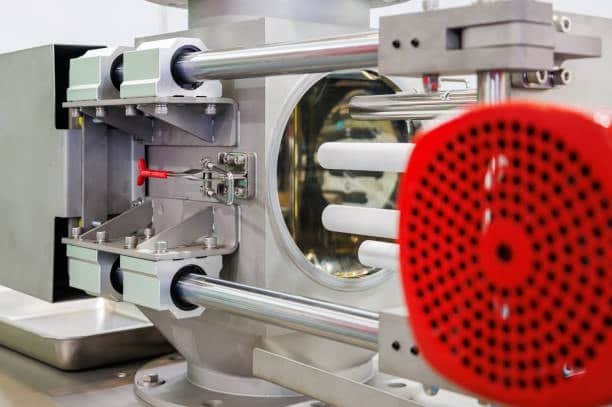

Designing for manufacturability is a decision of which machining process to use for the part. Depending on the material, part geometry, required features, and cnc threading tools, cnc turning, milling, drilling or grinding may or may not be needed. Processes must be chosen, which fit the requirements of the component and which are appropriate for the capabilities of the machinery that one has access to.

The proper choice of the machining process is a means to both functional requirements and efficient production. For instance, turning is perfect for cylindrical shapes, since using milling allows to create complex contours and flat surfaces, the presence of drilling provides for holes and grinding is required if very fine surface finishes or very tight tolerances are needed. By correlating the selection of process with the material properties, part geometry, and complexity of features, designers make parts manufacturable with confidence and at a low cost. Also, knowledge of the available machinery and how they perform enables one to cancel out processes that are unrealistic and in extremely high costs which in the long run reduces production times and consequent lead times.

Design Tip:

Design parts to utilise the least cost-gnu and efficient machining process. For instance, for big parts with simple forms it may be easier to use turning or milling as machining technology, whereas for more complicated shapes, additive manufacturing or other technical ways of cutting are preferable.

Designing for Manufacturability (DFM)

Design for Manufacturability (DFM) is a design method in which considerations to the ease & cost of manufacturing are given particular emphasis. This approach takes into consideration the constraints and capacities of machining processes during design stage, thus helping reduce time of production, reduce cost and enhance quality. DFM principles lead designers to cooperate early in the design story with manufacturing teams to find issues and solutions optimal prior to production.

1. Minimizing Tool Changes and Setups

It is of immense importance to reduce tool changes and machine setups in order to increase machining efficiency. Fabricating parts that can be machined in a single setup or small number of tool changes, minimizes downtime, makes parts consistent and reduces total production costs. Design of components with this in mind promotes use of features that can be reached and machined at ordinary positions of manufacturing without having to reorient the work-pieces. In addition, choosing machining processes and tooling taking into account hole diameter in which several of the features can be machined at a time can also make the production process more efficient. Through decreased changeover, and setups of the tools, manufacturers do more than make cycle times faster, they also reduce the possibility of error due to misalignment or improper fixturing. This just helps increase overall workflow efficiency, increase throughput, and help make cnc machined parts manufacturing processes more predictable and cost effective.

2. Simplifying Part Design

Whenever possible simplify part designs to reduce machining complexity. Do not add to many holes, pockets and items that would need to be machined extra times. Easiest parts to fixture mean reduced set up time and therefore increased production rate. Maintaining part designs simple not only enhances the time in machining but also yields high reliability because errors in machine production will be minimised. Complicated features may need special tooling, or multiple setups, which increase time and cost to remove material . Reducing unneeded features and paying more attention to basic functionality, designers can produce parts able to be held more securely in machining, and require less switching out of tools. This simplicity also facilitates relatively high-quality consistency along high production runs. In the end efficient designs support manufacturers to achieve efficiency, minimize lead times and deliver cost effective products without sacrificing performance.

3. Using Standard Tools and Processes

Design parts with standard machining tool and whatever processes will be available. Custom tooling is expensive, may add to the waiting time. Through designing for common tooling; the manufacturers can maximise the efficiency of production and eliminate costs. Keeping part designs simple not only improves time of machination, but gives high reliability, as errors of machine production will be minimised. Complex features require special tooling or multiple setups that will consume time and money. By eliminating unnecessary features and by concentrating more on fundamental functionality, designers can create items that can be more securely held during machining, and which engage less changing of tools. This ease also allows quite good quality consistency on high production runs. Eventually, efficient designs will help manufacturers gain efficiency, reduce lead times and produce cost effective products without compromising performance.

The Impact of Machining Design on Production Costs and Time

Proper machining design becomes highly important in decreasing both production costs and lead times. A well-optimised design is best able to minimize the consumption of materials, machinery downtime and avoid large scale post processing. Furthermore, good design decisions prevent expensive errors while manufacturing, so that the part will fit the tolerances and quality standards.

Besides, high-quality machining design can improve the general sustainability of the manufacturing process through minimizing the amount of wastage of materials and energy use. For instance, development of parts that need fewer setup or less tooling can greatly improve operations and prolongation of cutting tools’ life. Also, unnecessary complexity and expense can be avoided by staying out of overly tight tolerances where not functionally required, especially when designing for thin walls . When engineers and designers make the manufacturability a top priority during the design process, not only does it speed up the process and cut the expenses, but also facilitates a smoother operation between prototyping and large-scale production and allows for a dependable and consistent output.

For instance, the addition of improving fixturing and simulating of machining can lower the number of setups needed. Furthermore, it is possible to design parts easily automatable through CNC programming to increase manufacturing efficiency and also uniformity.

Conclusion

Machining design is an inseparable part of manufacturing process which directly affects the efficiency, cost, and quality of production. Understanding the key factors that influence machining (part geometry, selection of material, tolerances, surface finishes and machining processes) designers can produce parts that at the same time are functional and manufacturable. The integration of the Design for Manufacturability (DFM) principles ensures parts are manufacturable with the least possible complexity hence lowering the cost of production and squeezing timelines.

Involving DFM principles at the very beginning of the design process promotes involvement of design engineers and manufacturing team, which translates to good alignment between conceptual intent and actual performance. This forward looking plan avoids expensive design changes during the stages of production and augments general production reliability. In addition, CAD/CAM tools for machining design are also sophisticated to be able to simulate and analyze machining operations so that there is prior detection of problems and improvement in the placement of tools and operations. As demands for manufacturing evolve into more complex and time-critical terms, robust machining design does not only guarantee optimal output but also builds a business’ capacity to thrive amidst a highly competitive industrial environment.