Machining for aerospace cnc machining is perhaps one of the most challenging and complex areas of machining production in modern society. The industry in aerospace requires manufacturing of high performing, reliable and lightweight components that follow the highest safety/quality levels. Machining is very essential to produce these parts right from aircraft engines up to structural components where there must be precision strength and durability. This article explores the complexities of extracting machining used for aerospace, technologies involved, challenges associated and the fundamental benefits that it delivers.

The necessity of having exceptionally tight tolerances (in the sense of a few microns) in aerospace machining to guarantee performance and safety at great heights and under severe conditions is one of the key aspects of this activity. Commonly used materials in the aerospace applications: titanium, Inconel and high strength aluminum alloys, function because their strength will not diminish as temperatures rise, and they are not vulnerable to pressure variation or corrosive environments. However, the materials have a notoriously poor machinability because of their high hardness and low thermal conductivity. More sophisticated CNC machining methods like 5-axis machining, adaptive toolpath tactics and online process monitoring are used in order to cope with the issues of the difficult materials and ensure the necessary accuracy. What results from aerospace precision machining is not only increased safety and performance of aerospace systems, but also opportunities to innovate with lighter and more fuel efficient design that adheres to the rigid standards of regulations.

The Role of Machining in Aerospace

Machining in aerospace is accountable for the creation of aerospace machined parts that are not only functional but also able to withstand such extreme conditions as the high speeds, heat, pressure, and weight restrictions. These items require an especially flexible tolerance, and performance standards, ensuring it is safe and efficient in the air. Aerospace Machining possesses several techniques which are used depending on what features or qualities is needed to be developed on the finished product and they include turning, milling, drilling, grinding and EDM (Electrical Discharge Machining).

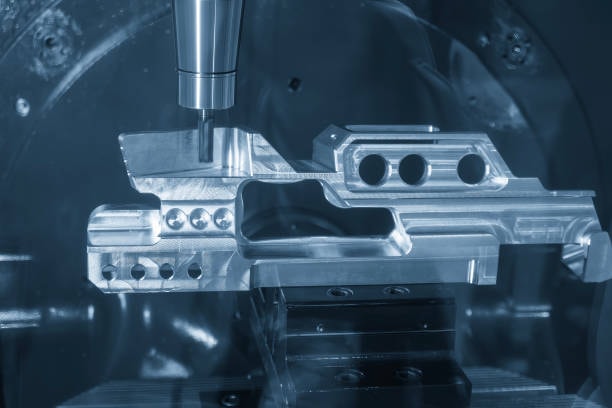

Among these methods, 5-axis CNC Milling, also known as 5 axis cnc machining, is a key pillar in aerospace machining because it has the ability to produce complex geometries and surfaces on one set up, cutting production time and enhancing part accuracy. This is particularly important while manufacturing turbine blades, structural airframe parts, and engine housings that require complex contours and multi-angle machining. EDM is used on the other hand where extreme accuracy is required on the difficult to machine alloys thus it is possible to produce fine features with components such as fuel injectors and engine parts. Each method has certain strengths and the selection of the technique for practical application is often dictated by the type of the material, complexity of the design and function requirements of an aerospace component to be manufactured. Taken together, these advanced methods of machining assures that aerospace parts comply with severe industry standards of strength, reliability and the ability to perform flawlessly even in the most extreme environments.

Key Materials in Aerospace Machining

Materials that provide high strengths, low weight and corrosion resistance are common for machining parts for an aerospace. These materials need in depth machining processes to maintain their integrity as well as their effectiveness. Most commonly used materials that are classified as materials used in aerospace machining are:

1. Titanium Alloys

Titanium is largely used in aerospace for manufacturing aircraft components because of its great strength-to-weight ratio and resistance to corrosion and tolerance to high temperatures. However, machining titanium can be difficult because it is hard and it work-harden easily. There is a need for specialized tools and cutting process to prevent tool wear and acquire accurate machining.

2. Aluminum Alloys

Aluminum is a never-ending material in aerospace due to its weighty and strong nature. The practice is widely used in fuselage construction and other important parts. Even though aluminum can be machined more easily than titanium, its properties still have to be precisely machined to prevent deformation or a poor finish.

3. Nickel Alloys

Nickel based alloys (Inconel and Hastelloy) are applied in high temperature applications, turbine blades and engine parts. These are very well suited for heat and strength, but they are very difficult the machine because of their hardness and tool degradation they result in rapid wear.

4. Composite Materials

As aerospace continues to develop, composite materials including carbon fiber and fiberglass are being used more and more. Such lightweight metals provide high strength, but still, weight is low. Working with composites, however, is complicated by tool wear and the necessity to preserve the structural integrity of the material in the case of its treatment.

Machining Processes for Aerospace Parts

Aerospace machining is the integration of traditional and advanced processes based on the type of part as well as the type of material being worked with. Machine operations used for aerospace creation include but are not limited to:

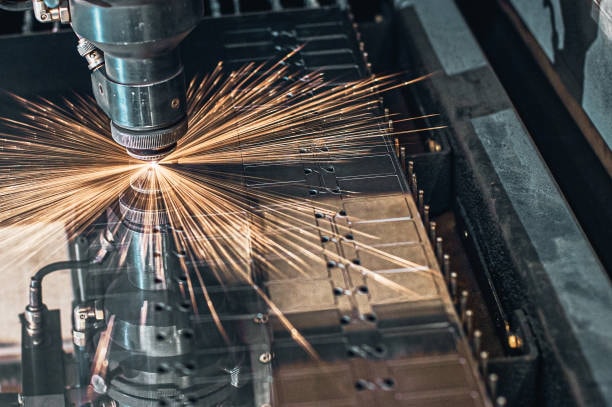

1. CNC Machining

CNC machining is a very automated and accurate technique applied in manufacturing aircraft. CNC machines enable the making of intricate geometries with absolute limits. Using advanced CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) software, aerospace manufacturers can create, for example, precision cnc machining of turbine blades, engine parts and airframe structures to unbelievable levels of accuracy.

2. Turning and Milling

Turning and milling are basic machining operations used in aerospace industry to form parts. Turning is mainly used to produce cylindrical part; milling produces more complex geometries. These processes are usually combined with CNC technology in order to get the specific dimension and finish quality.

3. Grinding

Grinding is employed in an aerospace machining to produce smooth finish and relieve small dimensions on pieces. It is widely used to finish turbine blades, and other parts that are needed to have high precision and smooth surface. The parts may also have a better dimensional accuracy through the process of the grinding.

4. Electrical Discharge Machining (EDM)

EDM finds its application in producing parts of complex shapes, intricate holes and very fine features which can not be machine milled using traditional methods. It is especially valuable for machining harder materials, including titanium and the nickel – alloys which are difficult to machine using traditional tools.

Challenges in Aerospace Machining

Although machining for aerospace has the ability of generating high performance components, several problems are associated with it:

1. Material Hardness and Tool Wear

Such aerospace materials as titanium and nickel alloys are very hard; therefore, the rate of tool wear increases. To counter this, manufacturers should take advantage of high performance cutting tools such as carbide or coated materials and cut parameters to extend the life of the tool.

2. Tight Tolerances and Dimensional Accuracy

The manufacturing of aerospace parts has to be to exacting specifications; tolerances are usually to within a few microns. To be achieving these tolerances highly accurate machinery is critical and careful attention to process control to preclude any variation that could impact performance or safety of the parts.

3. Heat Management

Aerospace machining tends to produce a lot of heat particularly in hard metals machining. Heat buildup can cause tool wear, part distortion and loss of material property. To avoid this, modern cooling and lubrication systems like flood cooling, through-tool coolant or fine chip removal / chip flushing are more commonly used to provide optimum machining condition.

4. Complex Geometries

Not unreasonably, complex geometries are common in many aerospace components such as fine holes, deep cavities and fine features. Such complicated shapes require high quality machining methods as well as multi axis CNC machines that can produce the required finish and precision.

Benefits of Aerospace Machining

Machining for aerospace companies, despite being faced with numerous challenges, comes with a number of core advantages which make it an essential component of the established industry:

1. Precision and Quality

Machining can generate components with extreme precision, owing to tight tolerances, thus it is critical in manufacturing processes for aerospace where even the slightest deviation may result in catastrophic future failures. CNC machining offers unmatched accuracy meaning parts will fit specific quality standards.

2. High Efficiency

Modern machining processes – multi-axis CNC machining, are able to create complicated parts in one setup, eliminating the need for more processes. This in turn improves manufacturing efficiency, and makes production time shorter.

3. Material Versatility

Aerospace machining is capable of handling various kinds of material such as metal, composite, and alloy. This versatility is made possible to design varied components for different applications from airframes to engine parts.

4. Customizability

Machining provides excellent customer tailoring making it possible for manufacturers to generate specialized aerospace parts. From a custom turbine blade, a custom aerospace structure, Machining allows for the flexibility of meeting any project’s specifications.

Conclusion

Machining for aerospace ensures that the high performance reliable and safe components used in aircraft, spacecraft and defense systems are produced. Machining methods that are precise, effective, and flexible are indispensable in the aerospace industry due to the exactness, speed and flexibility of them. From cnc machining aerospace parts that involve machining difficult materials such as titanium and nickel alloys to producing geometrically complex parts, machining is integral to the manufacture of parts with safety, reliability, and performance, airframe machining requires exacting standards which cryogenic technologies can provide.

Cryogenic machining is a modern approach to machining that is now used in aerospace manufacturing more and more to overcome the inconvenience of conventional cooling systems, and the problem is particularly acute when working with hard material like titanium and Inconel. In this method, the cutting zone is cooled by liquid nitrogen or CO2, which drastically reduces the amount of heat reaction generated and increases tool life without compromising dimensional accuracy. Apart from reducing the thermal distortion and enhance the surface finish, cryogenic machining also enhances sustainability as it eliminates or reduces the use of synthetic cutting fluids. Since many aerospace components require a high degree of strength as well as precision manufacturing in extreme operating environments, the incorporation of cryogenic technology in machining processes is a game-changer–high-capacity processes, consistent results, and strict aerospace quality.

Summary

Succinctly, aerospace machining refers to a specialty in machining which utilizes highly developed machining processes to produce components with outstanding precision, strength, and wear resistance. CNC machining, EDM, and grinding are high-end procedures being used in producing parts from high performing materials such as titanium, aluminum and composites on which the industry depends. Although some obstacles must be overcome, such as material hardness, close tolerances, and heat dissipation, the advantages of aerospace machining are necessary; including precision, optimization, material versatility, and customization, are important parts of the modern aircraft manufacturing process. With time, technology will continue to support machining in creating the future of the aerospace industry.

Furthermore, emerging machining technologies, including AI-based toolpath optimization, in-time quality monitoring, and the additive-subtractive hybrid systems, are also reconfiguring aerospace manufacturing capacities. These innovations not only make lead times smaller and the wastage small but also gives leeway to engineers to ensure that design boundaries are moved as they come up with lighter, stronger, and more aerodynamic components. Since the aerospace industry will require shorter production cycles and greater tailor-made solutions, machining will prove a critical phase for the process of transition into next-generation aircraft and spacecrafts. In this vibrant and dynamic area of study, the dynamic collaboration between the state-of-the-art machining and the science of material research keeps opening new horizon for aerospace development like never before.