From known machining methods of manufacturing processes and quality machining, such as cnc turning and milling, cnc machining the most significant difference between milling and turning is that they are the most predominant methods in use, including cnc turning . Even if both approaches are essential for material forming and component manufacturing, they both have unique mechanics, employ different tools, and are applicable to certain purposes. A clear understanding of the essence of milling and turning distinctions will empower the manufacturers pick the most optimum method to their needs therefore enhanced efficiency and cost saving.

What is Milling?

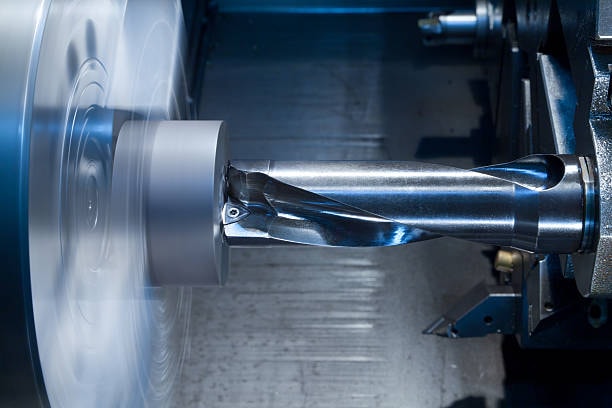

Milling is a process of using a spinning cutter to cut material away from a workpiece. The piece that is being worked in does not move while the cutter moves along several axes, providing one with an opportunity to fabricate the material into the required formation. The flexibility of milling operations is such that it can create cylindrical parts as well as generate a range of features including holes, slots, contours, and very detailed shapes, achieving the desired shape through techniques like cnc milling .

Milling machines are normally classified into two main classes depending on the orientation of spindle; vertical and horizontal. In vertical milling machines, which are also known as cnc milling machines, equipped with milling tools the spindle is up right. whereas it is horizontal in the case of horizontal milling machines, which differentiates them from turning operations and milling operations. Both types are precise with their cuts, especially in turning centers but in some cases, the use of a sub spindle can enhance this precision, while the distinguishing feature is seen in that how the tool is set during the process.

What is Turning?

Turning is an important technology in precision machining, ideal for creating precision parts, and is different from milling because it employs the rotational movement of the workpiece, also known as the stationary workpiece, rather than that of the tool. The turning procedure refers to clamping the workpiece by use of a chuck or collet and rotating it high speed on the lathe. Then, a single point cutting tool is applied for removing excess material and fabricating the desired geometry on the object – whether cylindrical, conical or spherical as required.

Milling vs. Turning: Key Differences

1. Motion and Operation

- Milling: Illustrates the rotation of the cutting tool to slice material from the still workpiece. The capability of milling to work on two or three axes allows it to address a broader set of difficult machining needs.

- Turning: The motion draws from the work piece, which rotates while the cutting tool is lodged to remove material from the object. Machining such basic cylindrical parts is perfectly suited for the stationary movement of a cutting tool along one axis.

2. Tool and Workpiece Orientation

- Milling: As a rule, the rotary part of the process is a cutting tool, while the workpiece does not move. This allows fabrication of highly complicated cutting operation, e.g. forming of grooves, slots and surface formation at various angles.

- Turning: While in milling, the cutting tool is held still, and the work rotates. The arrangement of turning is especially appropriate for cylindrical objects, but poses limited flexibility in obtaining different shapes.

3. Material Removal

- Milling: Milling allows the cutting of a material in horizontal and vertical directions. Milling processes can remove a considerable volume of materials in one cut, and such in the influences of such factors as cutters dimensions and feed rate.

- Turning: Falling off of material takes place when the rotating work piece crosses a cutting tool. Since turning operates by removing material in small bulk, it is excelling at obtaining tight dimensional tolerance on cylindrical work pieces.

4. Applications

- Milling: Accommodating for the creation of articles that are detailed in surface, irregular contours, slots and holes. Its fields of applications include various industries, including aerospace, automotive and toolmaking.

- Turning: Specialized for the production of round parts or cylindrical elements, such as shafts, pins and bushings. Turn Machining is widely used in manufacturing industries where precision is critical such as automotive, medical equipments and general industry.

5. Precision and Tolerances

- Milling: Capable of delivering superior accuracy and close tolerances especially where computer numerical control (CNC) systems are used. Because it can be adapted to multiple shapes and forms, milling can produce the intricate and complex geometries of parts.

- Turning: Generally guarantees accurate, uniform performance for cylindrical parts that places it in applications where evenness over the entire length must be achieved. While excellent in maintaining dimensions accuracy, its range of capabilities against varied part shape is much narrower to milling.

Conclusion

Milling and turning being fundamental machining operations carry with them their own list of capabilities and limitations. Milling is skilled at designing high-quality, complicated, complex parts with tight tolerances and outstanding precision; while turning is responsible for the manufacture of cylindrical parts and intricate parts with accurate details. The decision which between milling or turning to apply often depends on such unique demands on creating parts to successfully produce components with suitable materials . , such as its contoured nature or intricacy, complex shapes, and even the material it was composed of.

Summary

Mill and turn, however, are key engineering methods that have evolved to suit different production calls. Different motions are applied in milling and cnc turning to shape complex contours and cylindrical elements respectively. In milling, a turning motion on a rotating blade is achieved while in turning, a spinning piece is used along with a stationary cutting tool. When the manufacturers realize the unique strengths and capabilities of milling and turning, including the use of cnc turning centers and cnc lathes. they can select the best strategy for the highest output with the lowest cost. Modern manufacturing is highly dependent on both subtractive manufacturing techniques and methods like cnc turning and milling. like milling and turning because each process is critical for the production of intricate components and accurate round parts, including cnc turning machines .