This guide will discuss the differences between POM and Delrin materials as major, including aspects such as machining delrin . Read about their characteristics, their application, fabrication aspects and which material will suit your engineering project. Professional coverage of POM-C and POM-H comparison.

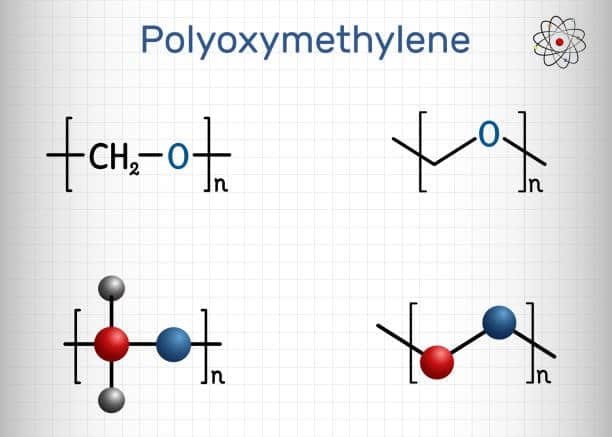

What is POM (Polyoxymethylene)?

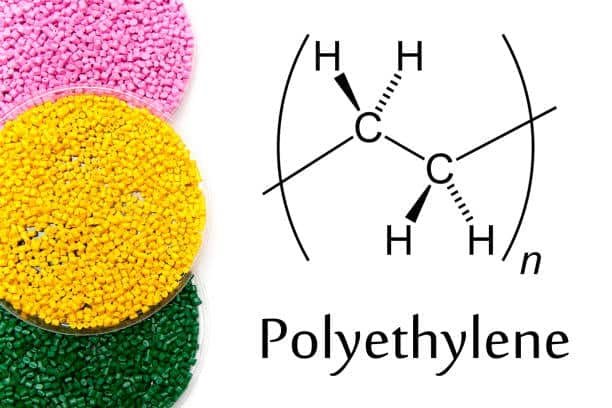

POM (Polyoxymethylene) is a high-tech engineering thermoplastic, the type of plastic tagged as an acetal. Delrin, also known as POM (Polyoxymethylene) or Acetal is an engineering plastic especially stiff, strong and chemically resistant. The all-purpose material stands out by its outstanding mechanical properties and dimension steadiness, as well as anti-abrasion and anti-fatigue properties low coefficient.

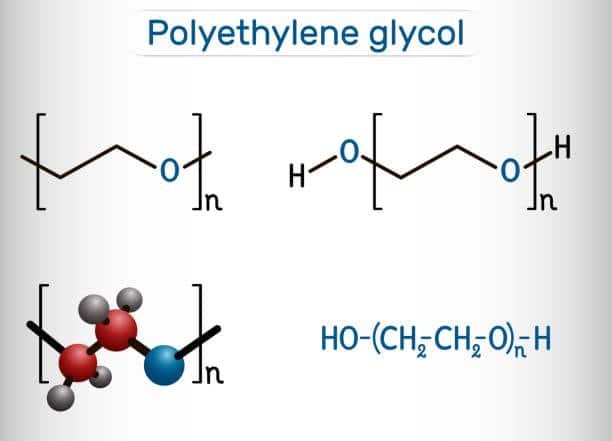

POM is in two main types namely the homopolymer (POM-H) and copolymer (POM-C) type which have other relative advantages when used in various applications injection molding. Because of its special molecular structure, the material offers great strength-weight ratios, a characteristic that makes it a perfect alternative to metal parts in most engineering related functions moisture resistance.

What is Delrin?

DuPont manufactures POM-H (homopolymer acetal) under the trade name of Delrin. Delrin engineering thermoplastics are of low friction, high stiffness and offer dimensional stability. First commercially synthesized at DuPont in 1956, Delrin has grown to have the meaning of high-quality acetal homopolymers exceptional dimensional stability.

The product is developed by an advanced type of polymerization method as distilled hydrocarbons are mixed with catalysts in a complicated process that ends up giving a refined form of plastic with exceptional features good creep resistance. The crystalline structure of Delrin forms its excellent mechanical properties than those of many other engineering plastics scraper blades.

Understanding POM-H vs POM-C: The Core Difference

Primarily, the main difference between POM and Delrin is the molecular structure and trade marks. Generally, POM-H possesses superior mechanical and physical aspects in relation to POM -C because of which it performs better in cases where you require high-quality, superior friction resistance hard-abrasion and low friction coefficient flexural modulus. Compared to Delrin, POM-C is not as strong or rigidity but it has some ease of processing and has good result in low friction contact heat treatment.

POM-H (Delrin) has a homopolymer structure which has even-mixing units but POM-C (acetal copolymer) allows more than one monomeric unit in addition to the usual CH2O units. This difference of structure affects the performance characteristics of the products and suitability of their application directly, contributing to their excellent dimensional stability .

Material Properties Comparison: Strength and Durability

The material has more desirable physical properties, including excellent fatigue and creep resistance, better bearing properties, compared to others when evaluated as a material of material properties high rigidity. The more crystalline structure normally leads to more tensile strength, stiffness, and hardness with Delrin standard twist drill.

The main strength properties are ultimate tensile strength which is 60-89.6 MPa in Delrin and Youngs modulus at 2.5-4 GPa. It can also be used in load-bearing applications where dimensional stability is the key requirement because the material is very rigid high clearance angle low coefficient of friction

insulin pens. The impact resistance of the two materials is also excellent, but Delrin has a tendency of being better in case of extreme stressful conditions gear wheels.

Thermal Properties and Temperature Resistance

One of the major point of difference between these materials is thermal performance. POM-C begins melting after 160-175 degrees Celcius. A little stronger, POM-H has a melting temperature that falls between 172-184 degrees Celcius articulated shells. This increased melting point increases the Delrin applicability to high-temperature use machining applications desired shape.

Delrin is a material that functions very well between temperatures of -40 to +120 o Celsius and it has high dimensional stability, exemplary dimensional stability operating throughout this range. Thermal expansion coefficient of the material is 75.7-202 x 10-6/degrees C allowing predictability under changing temperatures high precision parts.

Chemical Resistance and Environmental Performance

Both the POM and Delrin have great chemical resistance especially fuels, solvents and neutral chemicals. Both substances are however affected by strong acids, strong bases as well as long heating by hot water and steam. In spite of the fact that Delrin is more resistant towards rapid failure caused by exposure to organic compounds compared to other plastics, it is susceptible to strong acids, strong bases, hot water and steam centreline porosity.

The materials are shown to be excellent to withstanding moisture uptake by being much higher than many other engineering plastics, and that makes them suitable to be used in humid regions or where dimensional stability is important in spite of variations brought about by changes in the environment typical applications.

Mechanical Properties: Friction and Wear Characteristics

It is low in friction, and thus it is perfect in those application fields that require wear resistance like gears and bearings. Both Delrin and POM are good selections on applications that demand low friction and high wear resistance. POM-H (Delrin) will however normally provide better bearing qualities and abrasion resistance single fluted mills.

Self-lubricating properties of the materials mean that, in most applications, there is little necessity to externally lubricate wheels made of the materials, whilst the high hardness of the surface ensures high resistance to wear. These features give them special importance in the precision mechanical parts where durability is a key concern.

Manufacturing and Machinability Considerations

Many machinists like delrin because it is simple to work with, and can be machined on 3 and 5-axis machines, just like the metal parts. The two have great machinability, but POM-C is more easily machined than the other during manufacturing process.

Delrin can be produced in different ways such as CNC machining, injection and 3D printing. When machining, the material is dimensionally stable and it contains little to no deformation or shape loss. Management of heat in the machining process is however very important so as to ensure that there is no degradation of the material.

Cost Analysis and Economic Factors

The issue of cost usually affects the choice of selected materials. POM-C (acetal copolymer) is usually more cost effective an alternative to Delrin, especially when the properties of POM-H are not essential in an application. Nevertheless, the increased functionality of Delrin usually warrants the added expense in high performance applications.

Not just the cost of material should come into play when the total cost of ownership is calculated but also when it comes to machining time, wear of tools and long term performance. The cost of using Delrin can be balanced by the less time and greater quality of the part made due to its high machinability, and tolerance holding ability.

Application Areas: Where Each Material Excels

Delrin components will be likely to be found in the automotive and consumer electronics market and any market that requires high-performance engineering components. Delrin is especially good at high-strength loads, stiffness, and dimensional stability, especially in precision-gear applications, bearing, and structural parts.

POM-C fits in niche in situations where convenient processing is preferred over final performance, consumer goods, household appliances, and lower requirement applicances. Both the materials find wide usage in automotive, electronic, medical device, and industrial equipment.

Design Considerations and Engineering Guidelines

The engineers should take into account certain restrictions and prospects when working with such materials. Delrin has design limitations in common with a load of other materials actually Delrin does not have so many special restrictions but the general restrictions are worth remembering to keep to a tight tolerance and prevent distortion and fracture.

Important design factors are, whether a corner uses internal radii rather than sharp corners, unnecessarily tight tolerances, and requirements of walls to be thick depending on the type of walls used. The minimum wall thickness of the two materials usually lies between 0.8mm and 2.5mm of application demands.

Surface Finishing and Aesthetic Options

POM and Delrin are finishes using numerous techniques to attain wanted esthetics and performance attributes. Bead blasting gives any surface a uniform surface finish and greater durability that as-machined surfaces which mostly suffices the purpose.

Finishing Above very advanced hot stamping, silk screen printing, painting, laser marking and metalizing such as copper, chrome or aluminum coatings. These finishing techniques increase the use of the materials in applications that are consumer-driven and aesthetics.

Quality Control and Testing Standards

The quality control of POM and Delrin parts contains overall mechanical property tests, dimensional or size test, and environmental resistance testing. Tensile strength, impact resistance testing and analysis of thermal properties are some of the standard tests.

The quality control of the manufacturing should consider all the possible problems like shrinkage of large parts up to 0.05mm in Delrin parts. Unified process control in manufacture will provide similar material characteristics and dimension precision.

Environmental Impact and Sustainability

The question of environmental impact is gaining ground on the decision to choose the material. Both POM and Delrin can be recycled easier than several other engineering plastics, but profiles and technology available to recycle differ widely by region. Sustainability is also facilitated by the durability and long-life of the materials that make the products last longer in terms of lifecycle and increases time between replacement.

In end-of-life issues there are possibilities of material recoveries and their effects on the environment. It is on such grounds that environmental persistence of these materials is achieved since their chemical stability makes them superb when used in engineering applications pom machining.

Future Trends and Innovations

Current trends in POM and Delrin technology aim at refined performance properties, optimised processing techniques and special formulation aimed at new applications. The 3D printing abilities of both materials are being increased by breakthroughs regarding additive manufacturing machined pom.

Further research is going into bio-based substitutes and recycling processes that are more efficient than current efforts, without compromising performance. Integration of nanotechnology will offer better characteristics to its specific uses in the fields of electronics and medical devices.

Selection Criteria: Choosing the Right Material

The choice of material to be used in POM and Delrin is related to the particular application and requirements of performance as well as economics. Delrin applications where maximum strength, stiffness, and temperature resistance are needed are common, whereas cost-sensitive applications with only modest needs get along with POM-C pom plastic.

Important selection criteria are the operating temperature range, mechanical loading environment, and the exposure to the environment, dimensional stability, and manufacturing criteria. The optimum selection of the material is achieved through a good study of application specifications delrin machined parts.

Conclusion

It is important to realize that the POM and Delrin differ widely and this fact must guide the engineers and designers who often have to choose the material to be used in specific high-performance applications. Although Delrin is the best choice since it has the best properties, POM-C is a low-cost substitute where suitable applicability exists delrin cnc milling. This decision is made purely by balancing out performance requirement, cost, and various manufacturing methods. The two materials remain important in contemporary engineering, providing an industry stable solution in various types of product applications such as precision mechanical components as well as consumer products pom cnc machining.