Precision molding is a managed engineering process and design intent has to be maintained throughout machining to final assembly. Accuracy is maintained- or lost- in the production process such that even the most perfect designs may crumble due to the lack of coordination in processes and, consequently, causing dimensional variants or assembly incompatibilities. Uncontrolled processes may compromise early design accuracy, e.g. inconsistent datums or thermal distortions, which cumulatively compound through the design phases. Most people believe that the actual quality of precision molding is largely reliant on CNC accuracy, and most precision is lost due to lack of coordination in the processes and assembly of precision. When design intent is kept throughout all the manufacturing stages, precision mold manufacturing is successful.

Being a long time mold manufacturing engineer with decades of experience in managing tooling machining of automotive and electronic OEMs, I have seen how failure in process discipline transforms a good prototype into a nightmare in production.

Design Intent as the Foundation of Precision Mold Manufacturing

Design intent is the foundation of precision mould production because the precision targets that need to be maintained in later processes are defined.

The Role of Design Intent in Defining Precision Targets

Design intent extends beyond geometry – it gives functional requirements such as flow balance and thermal management that determines tolerances possible. It could happen that characteristics such as depth of cavities would pass on paper but they break during injection pressures without being known.

Setting Realistic Precision Goals

In electronics enclosure equipment that I designed, early target definition provided consistent results of ±0.01 mm, which is in line with the assembly requirements.

Importance of Datum Definition and Reference Strategy

Datums and references are also essential to keeping things aligned, inappropriate definition causes things to shift during machining or heat treatment, which undermines the overall accuracy.

Strategies for Robust Datum Control

Cumulative errors are avoided by using primary datums which relate to functional surfaces which was learned during the moulding of medical equipment where misalignment led to ejection problems.

Why Unclear Design Intent Leads to Downstream Variation

Mist interpretation of intent allows variation down the line since machinists understand ambiguities to be different, so the fit may be different or the cooling unsymmetric. This ties into the core precision mold definition, where precision emerges from intentional, preserved accuracy.

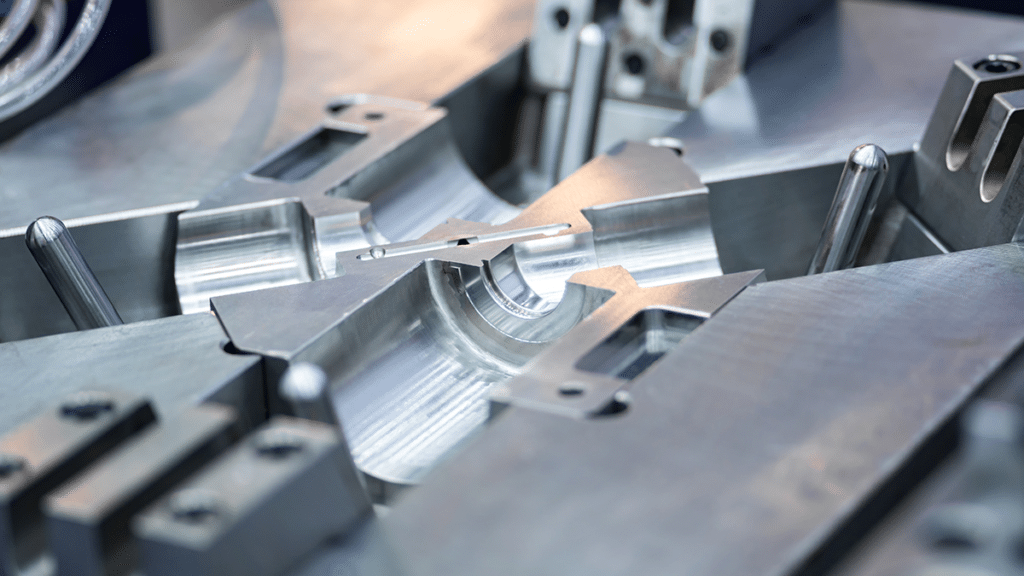

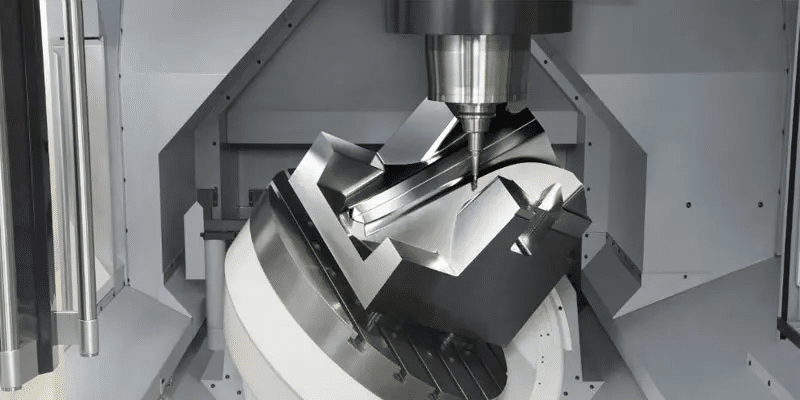

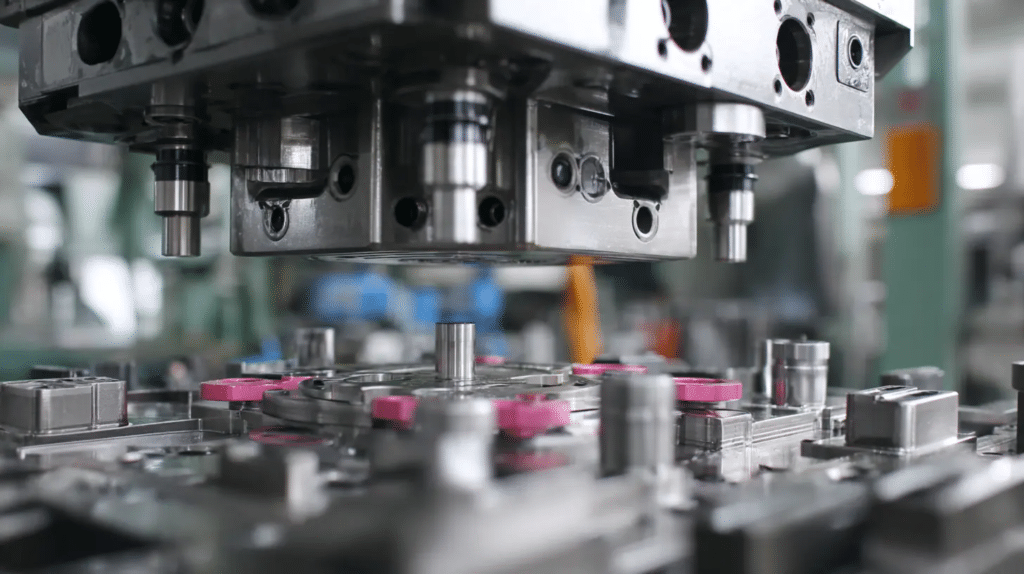

Machining Strategy and Process Consistency

The machining strategy will either entrench accuracy or be worn away and only focuses on order and regulation instead of raw potential.

Why Machining Sequence Matters

Sequence has an influence on stress distribution- roughing prior to finishing reduces distortion, whereas reversing this may cause warpage which cannot be completely eliminated by any means.

Optimizing Sequence for Material Integrity

Sequencing in automotive connector applications using intermediate stress relief maintained sub-0.005 mm features through cavities.

Datum Preservation Across Roughing and Finishing

Maintaining datums means that references will be accurate; any loss during the process results in offsets which magnify multi-cavity tools.

Techniques for Datum Maintenance

The references will be maintained without recalibration delays by using clamping strategies and in-process gauging as I use with high-volume runs.

Process Repeatability vs Peak Accuracy

Reproducibility is better than best accuracy; a process with a profit of ±0.002 mm each time is better than one with a profit of ±0.001 mm occasionally because variation propagates to assembly issues.

Balancing Accuracy with Reliability

Being conscious of my tooling lines SPC (statistical process control), has maintained repeatability, without falling into the traps of pursuing unrealistic heights.

Heat Treatment and Its Impact on Dimensional Stability

Depending on how it is incorporated into the workflow, heat treatment may stabilize or sabotage precision.

Stress Relief and Distortion Risks

Stress relief annealing eliminates internal stresses during machining, but inappropriate quenching leads to deformation to a maximum of 0.03 mm in hardened steels.

Managing Distortion in Practice

The warpage was reduced to a minimum using vacuum treatments as applied to my automation molds in the industrial automation.

Why Heat Treatment Must Be Planned, Not Corrected

Planning incorporates treatment with design- planning shrinkage avoids post-treatment grinding that removes critical areas.

Proactive Planning Approaches

Such materials as H13 can be predictable when subjected to the same treatment; variations cause hardness to vary unevenly, increasing the wear rate and losing accuracy as the material cycles.

Relationship Between Material Behavior and Precision Retention

The use of pre-hardened alloys in electronics tools that I have managed decreased treatment variables, which last longer without being misleading.

Material Selection for Long-Term Stability

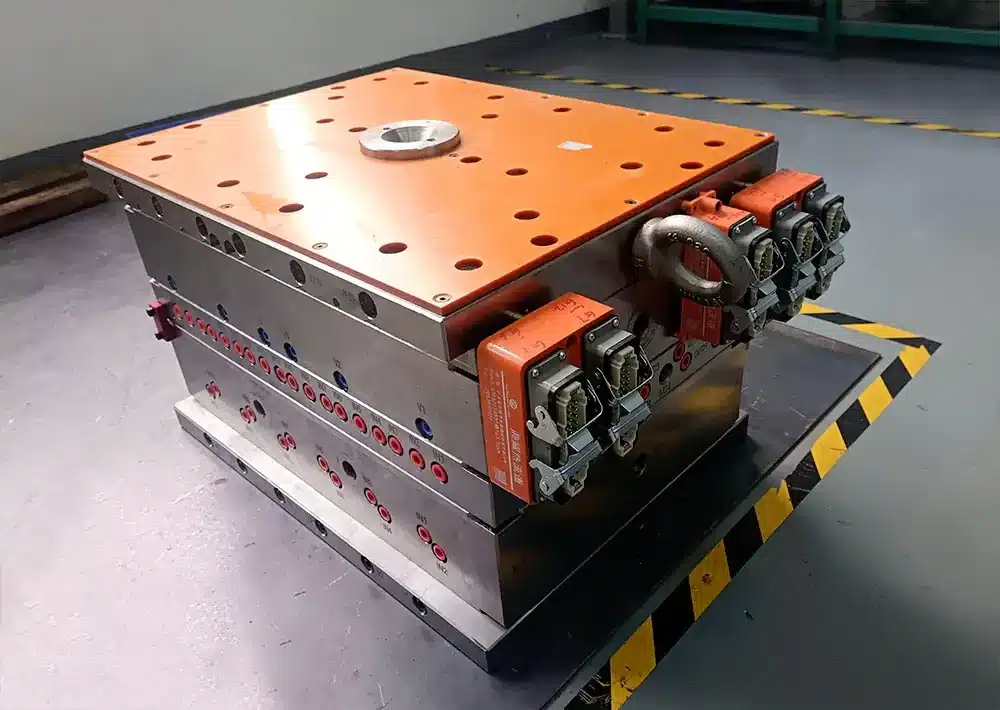

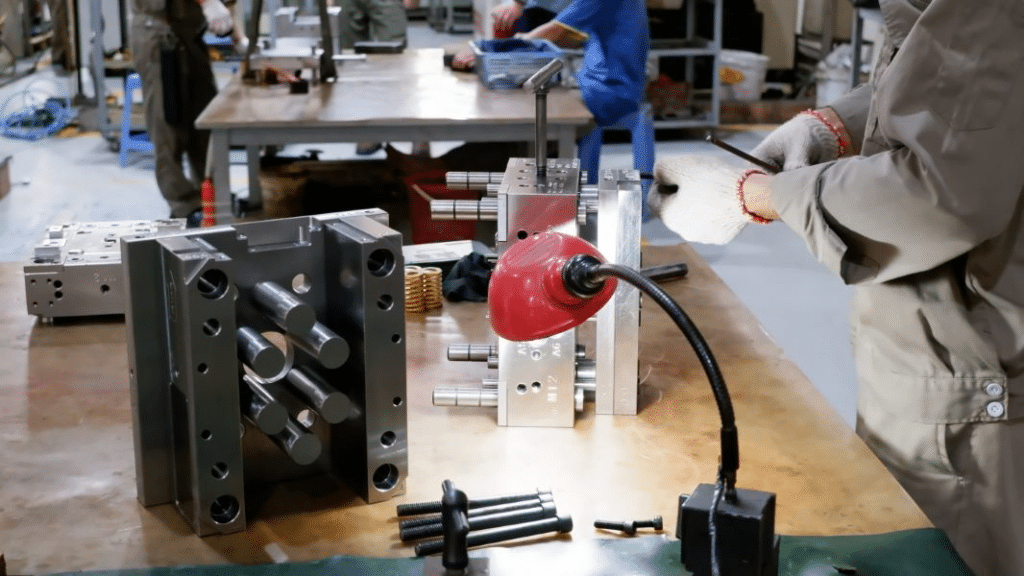

It is precision assembly and here the theoretical accuracy is confronted with reality, and it is often in this regard that the operational fate of the mold is determined.

Precision Assembly and Fitting Control

Fitting accuracy Components are mated without force and stress concentrators do not occur, resulting in cracking or misalignment.

Importance of Fitting Accuracy

My high-precision constructions have avoided flash using lapped fits in slide mechanisms with a 0.002 mm honed fit.

Achieving Micron-Level Fits

Assembly Tolerances are stacked up and may shift parting lines during assembly, causing leaks or uneven filler.

Stack-Up Effects During Assembly

This is regulated by GD&T applications, such as in multi-insert tools where it was maintained flat within 0.01 mm.

Mitigating Stack-Up Risks

This is controlled by GD&T applications in tools of multi-insert where it retained flatness within 0.01 mm.

Why Assembly Often Determines Final Precision

Assembling identifies defects on the upstream; lack of control here negates the accuracy in the preceding steps resulting in field failures. Common precision mold manufacturing mistakes originate in overlooked fittings, turning stable components into unstable systems.

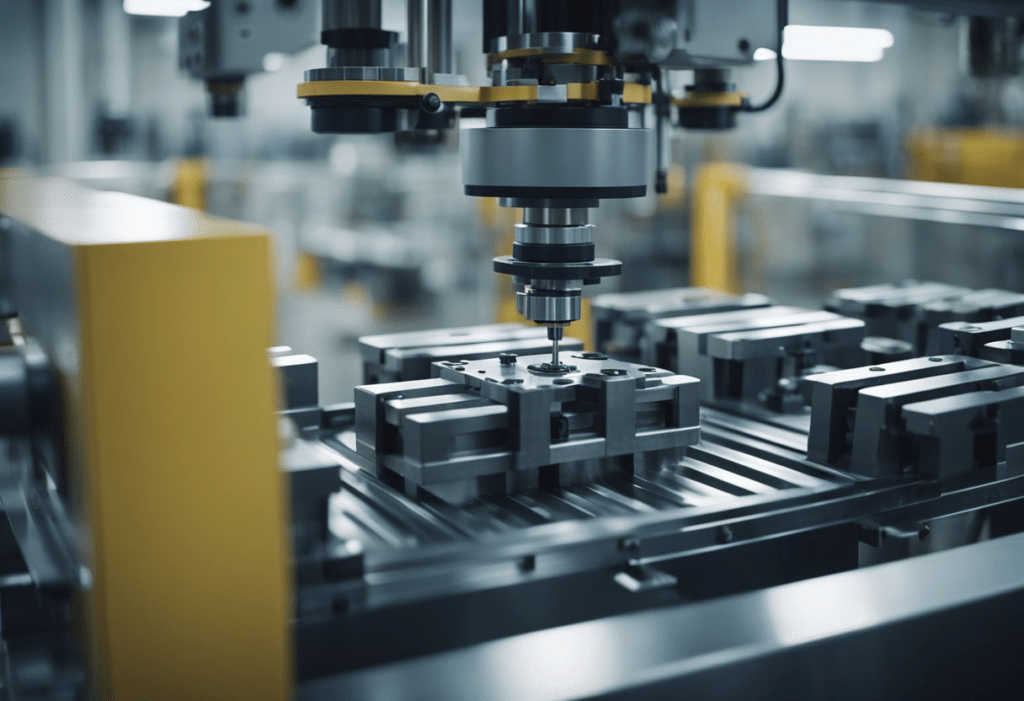

Verification, Measurement, and Process Feedback

Measurement is an ongoing process, not a destination, that is incorporated in verification to correct deviations at their initial stages.

Why Inspection Is Part of Manufacturing, Not a Final Gate

Considering inspection as a part of the process, real-time corrections are possible, which ensures that no error is transmitted to the assembly process.

In-Process Inspection Benefits

In my automotive programs after roughing CMM checks detected 0.015 mm deviations, before they accumulated.

Role of Feedback Loops

Measurement feedback loops correct processes such as tool wear control feeds to maintain constant finishes.

Implementing Effective Loops

On high volume systems that I have automated the logging process, the yield has been enhanced since trends are recognized in advance.

How Verification Prevents Cumulative Error

Checking stops cumulative errors, one stage passes on correct work, maintaining fine integrity of the mould.

Tools for Error Prevention

Complex geometries have been detected using laser scanning which has proved very useful in identifying minute changes at the early stage.

Precision Mold Manufacturing Requirements as a System

The production of precision mold should be system-oriented in which a standalone excellence cannot work out without a system.

Why Precision Mold Manufacturing Must Be System-Driven

Majority of steps only succeed in concert, a system approach brings them together to guard precision as a whole.

Systemic vs Siloed Approaches

The transition to the integrated workflow within my teams decreased the number of defects by 18 percent, which proves the importance of coordination.

Coordination Between Design, Machining, Heat Treatment, and Assembly

The movement between processes does not cause variance, coordination makes sure of this, – design informs machining, which prepares treatment.

Cross-Stage Collaboration Strategies

Electronics tooling gaps have been overcome via weekly alignment meetings which have ensured intent remains.

Importance of Documented Manufacturing Standards

Documented standards impose uniformity, be it datum protocols up to treatment specs and eliminates operator variability. This reflects core precision mold manufacturing requirements, where systemic discipline underpins reliable builds.

How Manufacturing Quality Affects Injection Molding Stability

The stability of injection moulding is directly controlled by manufacturing quality because changes in the build occur in the form of inconsistency of the process.

Relationship Between Mold Build Quality and Process Window

The process window can be expanded by high quality of builds giving the ability to tolerate the resin or environmental change without flaws.

Building Robust Windows

My medical molds used controlled assembly, which widened windows that maintained a ±0.02 mm tolerance to changing conditions.

Why Manufacturing Variation Appears as Molding Instability

Variation in manufacturing such as an uneven cooling channels presents itself in the form of molding warpage or cycle variation.

Tracing Instability to Build Flaws

Flash is commonly associated with the lack of assembly in audits that I performed rather than the failure of work.

Long-Term Impact on Cycle Consistency and Yield

Low quality destroys yield over the long-term and scrap is more frequent, solid builds are consistent over millions of shots. Explore the manufacturing quality impact on molding stability for deeper insights into these dynamics.

Conclusion — Precision Is Preserved Through Process Discipline

Precision mold manufacturing is the science of safeguarding design purpose using all controlled processes, machining approach to final assembly. Due to the focus on systemic coordination and risk awareness, engineers will be able to provide molds that may withstand pressure during the production process. This would encourage consistent performance with precision not just by chance but designed throughout the performance.