Meta Description: Learn all that there is to know about side action injection molding including the types as well as the application and the design. Get an understanding of complicate undercut geometries in making plastic parts by using slides, injection molding lifters, and cams.

The design of the parts to be manufactured is always complicated or with complex forms; at this point, the straight-pull injection molding tends to fail. It is in this segment that side action injection molding has become essential because it offers the manufacturers an opportunity to manufacture the parts with undercuts, holes and slots as well as other features in mold design that would otherwise not have been manufactured using the traditional means. Side actions are inserts mounted to the mold to generate undercut geometry, opening the design of part to possibilities, and yet still remain manufacturable.

What Are Side Actions in Injection Molding?

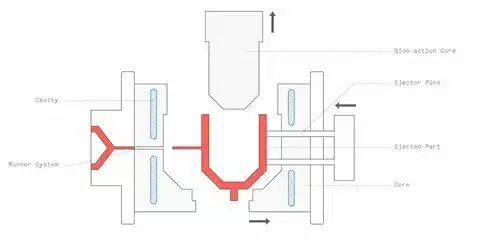

Side actions (sometimes called side-pulls, cams, or cam-actions) are specialised mold mechanisms that form the undercut features of injection-molded parts. Undercut features, including internal undercuts, are in perpendicular relation to the primary parting line and thus valuable with any straight-pull mold, therefore raising side actions significant when assemblies have complicated geometries.

In a normal injection molding, the mold opens on one parting line and the part is pushed out in a straight direction. Side actions are however the solution when some part contains undercuts – shapes that would not allow straight ejection. The side-action mold surfaces are pulled back so the part could be released to the mold by a cam device in the mold, which may also include an ejector plate for smooth part ejection .

These mechanisms move in a horizontal motion perpendicular with the direction of the opening and closing axis of the mold, so that they can provide the space of complex features during the molding process and subsequently move out of the way to occupy part ejection space. The ability substantially enhances invention opportunities and does not diminish efficiency and accuracy of the injection molding practices.

Types of Side Action Mechanisms

Injection molding, as an industry, has multiple classifications of side action mechanisms and they have a variety of applications and geometrics. These variations in types, including injection molding sliders, are important because they make manufacturers know the best solution they should use depending on part demands.

Slides The most popular types of side action mechanism are slides. Slides generate and form exterior undercut characteristics by folding in place through a cam as the tool travels shut. They also work best in development of features on the outside of parts, including external undercut features, which are impossible to form with the main core and cavity. Mold opens and closes moving the slides laterally under the control of cam pins to provide accurate positioning and timing.

Lifters are also similar, though they are applied to inner geometries. Relieving Undercut features Lifters generate and cut off undercut features. Likewise slides, lifters torque towards the tool closing and out of the hole as the tool opens using a cam. Such mechanisms are perfect in making internal tabs, over hanging characteristics, or any complicated internal geometries that may have captured the part during ejection and are designed to release internal undercuts.

Hand-loaded cores The low-volume production can be carried out with a more reasonable cost at hand-loaded cores. The slides or lifters are the alternatives to hand-loaded cores, that is, hand placed features that are molded over and then manually released. They are extremely labor-intensive yet cost-effective that are utilized in prototype and low-volume tooling exercise, often complementing additive manufacturing techniques .

Advanced Side Action Technologies

In addition to standard slides and lifters, there exist also special side action technologies, including those utilizing an angled pin, to meet special manufacturing needs and to allow still more complex part shapes.

Unscrewing actions Actions like unscrewing offer automated features to the threaded ones. An unscrewing process is an automated motor driven or manual hand screwing, which form screw or threaded features, also known as threaded features. These mechanisms avoid damage to the thread, by unwinding it carefully between cycles, to maintain reliable quality of the thread and integrity of the part. Unlike hand-loaded systems, unscrewing actions are economical at large volume production, although they are more costly in low production runs.

Collapsible cores Collapsible cores are used in addressing circular undercut features and large internal threads. Collapsible cores are also devices that cause a circular under cut to be released in a technique comparable to a lifter. They are intelligent mechanisms that have the ability to fall in-wards giving a clearance to the ejection of parts and still preserve the integrity of complex curved designs.

All the technologies have unique benefits based on part geometry, production volume/rate, material quality, tool steel, and, therefore, it is important to make an informed selection that suits a project.

Design Considerations for Side Action Molding

The design used in side action injection molding must be considered in different aspects regarding manufacturability and cost. Since side actions are not aligned with the common tool direction, undercut features need specially-made draft angles related to the direction of action motion to ensure smooth part ejection .

Draft angles are especially important in side action applications where the angle has to be large enough to allow the movement direction of the side action to open and close but not the main mold opening direction. This usually necessitates various draft accentuations on various parts detailing of the same part, which complicates the designing process, especially when t shaped lifters are employed .

Uniformity of wall thickness is still a practical concern, but added to this is the side actions. Mainly stress concentrations or fillings in the transition between side actions and the main part geometry should be avoided. The pattern in material flow is greatly affected in case of side actions, which might interfere with the strength and appearance of the parts.

With side actions additional complexity is added to gate placement because the designer must work out how the material will move around the mechanisms inside the side actions. With the side-action formed to create the inside core of the test tube and the parting line placed down the center of the test tube, the push eject part can be removed sideways and considerably less draft angle is needed since the parting line is finished next to a wall in the test tube (it used to be inside the part itself), showing how clever gate location is an efficient part designer.

Manufacturing Benefits and Applications

Side action injection molding provides a lot of advantages related to manufacturing, much more than what can be achieved by allowing complex shapes. Side actions have a positive benefit in that they allow more of the choices of what part geometries your part can have and allows designers an unequivocal freedom in creating a part.

Among these benefits is the minimization of the secondary operations. Side actions can be used instead of molding simple parts and subsequently machining or assembly complex geometry features into the details. This combination decreases handling, assembly production time and quality problems which can arise due to several steps of manufacturing.

Side actions also allow development of functionality features that enhance performances of parts. Snap-fit, living hinges, cable management and ventilation hole features can also be produced directly into parts without the need of additional fasteners or required separate manufacturing steps mold cavity.

The technology is most efficient when it comes to uses where features location and dimensional accuracy are required ejector pin. Side-actions may be a frustratingly useful part of your parts design tool chest, in the sense that use of them enables you to offer parts with much more functionality, to the point of their being necessary in complex assemblies and high-performance applications angled guide pin.

Cost Implications and Economic Factors injection molding lifters

Although side actions are useful in enhancing design opportunities, they come at an extra expense which should also be taken into consideration. Side actions may escalate the cost of molding production to a significant level and it is therefore imperative that one performs cost-benefit analysis to be successful in the project.

Side action also entails high starting tooling cost. The mechanisms themselves involve sensitive machining, special parts and further sophistication in the design of molds. These up front costs have to be offset against the possibility of saving on secondary operations and assembly time and part consolidation.

There is also a slight possibility of slowing down the production cycle time because of more moves involved in the side action operating injection molding press pushing. Modern side action systems, however, are very streamlined and the time gained back is, at least sometimes, insignificant as compared to the time saved by foregoing secondary operations injection molding press.

Volume is an important factor in regard of cost justification. The increased tooling would normally be worth the cost on high-volume production requirements, and on low-volume applications it may be better to go with hand loaded solutions or to change the design to make side actions unnecessary altogether.

Quality Control and Manufacturing Precision injection molding sliders

Side action injection molding requires an extra-level of quality control and precision production. These systems are very complex and a proper monitoring and maintenance are necessary to maintain stability in certain part quality and dimensions.

The timing and synchronization then come to play significance as the side actions should be in a flawless synchronization to the main mold opening and closing. These timing problems may end up in derailing of parts, breakages of tools or lead to stalling of the production. New injection molding machines have installed advanced control which controls and automatizes side action timing.

The complexity of side actions also gets involved in wear and maintenance considerations. Its moving parts will wear and the wear will cause friction, so they will need periodic inspection and maintenance. Tool design and maintenance can however, ensure a very good tool life and maintain uniform part quality over the life of the tool.

With side actions, dimensional verification is also more difficult since the conventional methods of measuring things may not effectively measure aspects formed by such mechanisms. State of art inspection tools and holding devices might be mandatory, to meet the design requirements.

Future Trends and Technological Advances

Its industry of side action injection molding is currently making progress through the development of technology that allows them to do more at a lesser price and greater accuracy. Side action systems are undergoing an automation process and integration into industry 4.0, changing the old process and monitoring system.

Side action mechanisms are incorporating smart sensors and predictive maintenance systems that will give real time feedback of the operation and then predict their maintenance requirements before it fails. The technology minimises downtime and enhances general equipment effectiveness.

Premium material and plating is prolonging life of parts used in the side action and cutting friction and wear. These enhancements have been translated into an extended tool life, low maintenance cost and consistency of the part quality.

The latest simulation and modeling software is still in development, which allows designers to have more useful tools to determine side action performance and refine their models before constructing a tool. The capabilities trim the amount of development time, and increase the success rate of the first attempt using complex side action applications.

Conclusion

The latest simulation and modeling software is still in development, which allows designers to have more useful tools to determine side action performance and refine their models before constructing a tool

cylindrical lifters. The capabilities trim the amount of development time, and increase the success rate of the first attempt using complex side action applications.