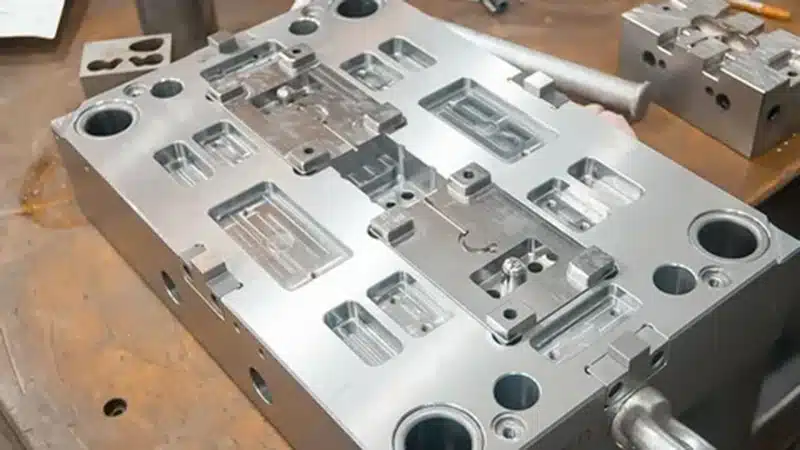

Surface finishing in the context of precision mold components involves refining the texture, roughness, and surface properties of key elements like cores, cavities, and inserts to optimize their operational behavior during injection molding cycles. This goes beyond superficial enhancements; it directly impacts wear rates by controlling how surfaces resist abrasion, influences friction to ensure smooth component interactions, and affects overall molding behavior by facilitating consistent resin flow and part demolding. Many buyers assume smoother or shinier finishes automatically improve mold performance, which is often incorrect—excessive smoothness can lead to issues like vacuum locking or reduced lubricant retention without providing real functional benefits. Surface finishing defines how precision mold components interact, wear, and perform—not how refined they look. Surface finishing should be selected based on functional interaction and long-term performance, not cosmetic appearance. Drawing from years as a tooling engineer troubleshooting mold failures in high-volume production lines, I’ve seen how mismatched finishes accelerate wear or cause inconsistent parts, turning efficient tools into maintenance burdens. This article demystifies the options to help mold designers, tooling engineers, and OEMs make decisions rooted in practical engineering rather than visual appeal.

Why Surface Finishing Matters in Precision Mold Components

Surface finishing is essential in precision mold components because it governs the interaction at contact surfaces, where friction and wear can compromise performance over repeated cycles. Contact surfaces, such as those on sliders or ejector pins, endure constant motion and pressure, so the right finish minimizes galling and heat buildup—I’ve encountered cases in automotive tooling where inadequate finishing led to adhesion between components, spiking ejector forces and causing part distortion. Non-contact surfaces, like the backs of mold bases, often require minimal refinement to avoid unnecessary costs, highlighting the need for targeted application.

Over thousands of molding cycles, surface finish influences consistency: it resists degradation from abrasive fillers in resins, preventing progressive erosion that widens tolerances and introduces variability. Component interactions amplify this effect—a rough finish might promote better grip in certain alignments but accelerate wear elsewhere, underscoring why finishing must align with the mold’s operational demands for sustained reliability.

Common Surface Finishing Options and Their Functional Roles

Common surface finishing options for precision mold components each address specific functional challenges, but their value depends on the component’s role, not a one-size-fits-all approach. As-machined CNC finish, resulting from milling or turning without secondary processing, typically achieves an Ra of 1.6-3.2 µm and solves the problem of basic dimensional readiness for non-critical areas like structural plates; it’s appropriate for low-friction environments where cost control is key, but unnecessary or even harmful in high-wear zones where tool marks can trap debris and promote corrosion.

Ground surfaces, produced via abrasive wheels, refine to Ra 0.4-0.8 µm and excel at providing flatness and consistency for sliders or inserts post-heat treatment, addressing distortion issues from upstream processes—ideal for applications requiring stable mating but potentially counterproductive if over-applied, as it can induce residual stresses in brittle materials. Polished finishes push roughness to Ra 0.2 µm or lower through buffing, facilitating smooth part release in cavities for glossy resins; this is suitable for optical or medical molds where demolding consistency matters, yet harmful when it removes beneficial microstructures that aid lubrication, leading to faster wear in dynamic components.

Lapped surfaces achieve sub-0.1 µm flatness using loose abrasives, solving ultra-precision fit problems in bushings or alignment pins to prevent leakage in cooling channels—appropriate for high-accuracy assemblies but unnecessary for general features, where the labor intensity inflates costs without proportional gains. Coatings, mentioned here as enhancements like PVD or nitride layers, add targeted hardness to wear-prone ejector tips, extending life in abrasive conditions but should be avoided where they might delaminate under thermal cycling. In my consulting work, sequencing these—starting with grinding for form and polishing selectively—avoids over-finishing that undermines durability.

Surface Finishing as Part of the Manufacturing System

Surface finishing cannot be isolated from the broader manufacturing system, as upstream processes like machining establish the foundation that determines finishing feasibility and outcomes. Poor initial cuts leave deep marks that require aggressive grinding, potentially distorting thin sections or introducing heat-affected zones that compromise hardness. From experience optimizing electronics molds, I’ve found that high-quality roughing minimizes downstream refinements, ensuring finishes enhance rather than correct underlying flaws.

This system-level integration is why partnering with providers skilled in precision manufacturing for molds matters—they align processes for consistent results. For baseline setups, reviewing CNC machining for precision mold components reveals how initial accuracy sets the stage for effective finishing without excess material removal.

How Surface Finishing Affects Injection Molding Results

Surface finishing in precision mold components directly shapes injection molding results, particularly in part release where controlled textures prevent sticking while allowing clean separation. An Ra of 0.4-0.8 µm on cores promotes reliable demolding for engineering plastics, reducing cycle times and defects like tear marks, but overly smooth finishes can create suction effects in undercuts, complicating ejection. Surface replication transfers mold textures to parts—ground finishes yield matte appearances suitable for functional grips, while polished ones produce high-gloss aesthetics for consumer goods.

Cosmetic outcomes like shine must not overshadow function; roughness that aids flow uniformity trumps visual perfection in structural parts. Understanding this via injection molding quality helps prioritize finishes that enhance yields without introducing variability.

Surface Finish, Wear, and Long-Term Stability

Surface finish profoundly influences wear mechanisms in mold components, as initial textures dictate how abrasion, adhesion, and corrosion progress under cyclic loads. Ground or coated surfaces distribute stresses to slow erosive wear from glass-filled resins, potentially extending maintenance intervals from every 50,000 to 200,000 cycles by reducing galling on sliders. However, mismatched finishes—like polishing on high-impact areas—can strip protective layers, accelerating degradation and leading to dimensional drift that manifests as flash or uneven fills over time.

Long-term stability relies on this balance: finishes that retain lubricants preserve alignments, but over-refinement invites brittleness. Strategies to optimize mold component service life emphasize selecting finishes that match duty cycles for enduring performance.

Common Misunderstandings About Surface Finishing

A pervasive misunderstanding is that a mirror finish equates to superior performance, disregarding how it can diminish friction benefits or increase costs without addressing core wear issues. Another: assuming surface finish can compensate for subpar machining, when deep underlying defects persist and emerge as failures regardless of polishing. Finally, believing all mold components require high-level polishing ignores that many— like bases or non-mating parts—function optimally with basic grinding, avoiding unnecessary processing that could introduce distortions.

These misconceptions often arise from aesthetic priorities; shop-floor evidence shows function must lead.

How OEMs Should Choose Surface Finishing Rationally

OEMs should begin by classifying surfaces as functional (e.g., cavities needing release) or interaction-critical (e.g., sliders requiring low friction), then balance finish levels like Ra 0.4 µm against wear resistance to avoid over-finishing that hikes brittleness. Align choices with part function and mold role—high-cycle tools favor coatings for endurance, while prototypes might suffice with as-machined textures.

This engineering guidance, drawn from collaborative audits, focuses on performance metrics over shine for cost-effective durability.

Conclusion — Surface Finishing Is a Functional Choice

In summing up, surface finishing stands as a pivotal functional choice in precision mold components, directly supporting interaction, wear resistance, and overall system stability. By approaching it through engineering logic—factoring in trade-offs with upstream processes and downstream results—toolmakers achieve reliable, long-lasting molds without excess. Surface finishing should be evaluated as a functional engineering choice that supports performance, stability, and service life—not as a cosmetic enhancement.