Have you ever been bewildered by terms such as crest, flank, and pitch when dealing with screws or CNC threads? You’re not alone. Enter any machine shop or engineering conference, and you will hear those words bandied around like everybody was born with them. The thing is that to understand the operations with fasteners, precision machining, or assembling work, one should master thread terminology.

Learning about threading terminology is not only important as a way to sound professional, but it can also have a direct influence on the quality of assembly, cost-efficiency, and workflow optimization of both machinists and hobbyists, as well as engineers. Being able to determine thread specifications with confidence cuts out guesswork, minimizes rework, and assures your assemblies work the way you hoped.

Why Thread Terminology Isn’t Just Jargon

Thread terminology is the common language that describes geometry, fit, and action of all threaded fasteners you are going to come across. Such terms are not arbitrary, but are accurate measurements and specifications that will tell you whether a bolt will cling when stressed, whether the parts will fit together, or whether your CNC code will cut acceptable threads.

Take the following situation in the real world: A machinist incorrectly identifies the pitch diameter specification of an important automotive part. The result? Components that seem appropriate during assembly but that do not perform during operational loads cause expensive recalls and safety issues. These costly errors can be avoided through knowing the principles of the thread form guide and making sure that all people speak the same technical language.

Break Down the Categories: A 36-Term Roadmap

We will divide these key terms into three digestible categories that build on each other in order to form a complete foundation of thread classes explained and practiced.

A. Fundamentals of Thread Geometry

Thread Form The shape profile of the thread is most commonly triangular (power transmission), square (lead screw), or trapezoidal (power transmission). Both forms have certain applications depending on their strength, efficiency, and manufacturing needs.

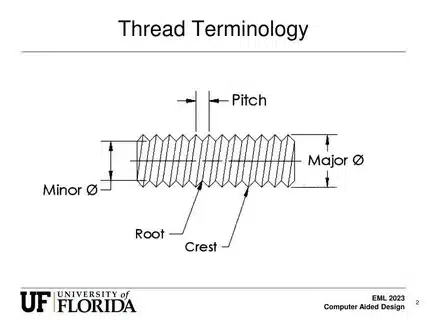

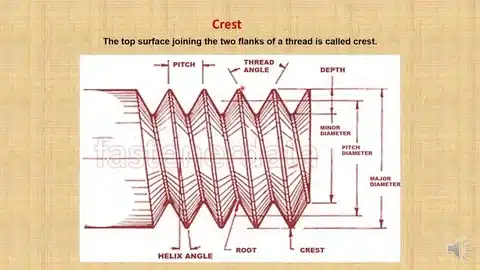

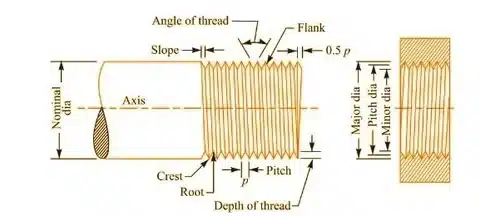

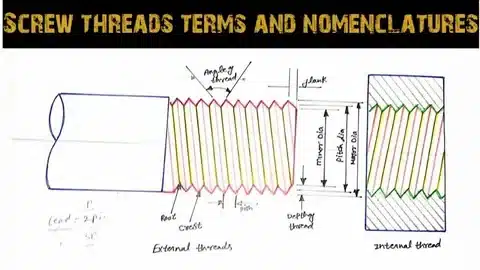

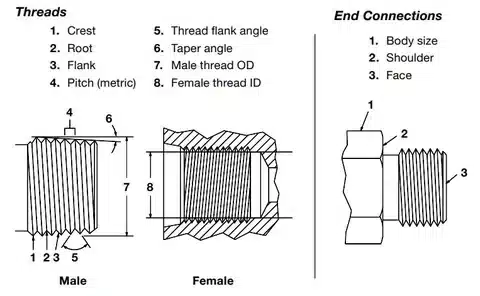

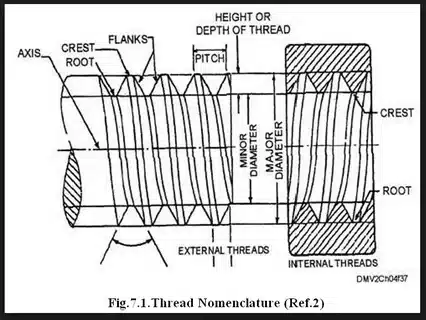

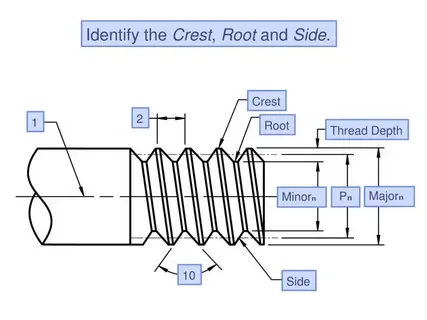

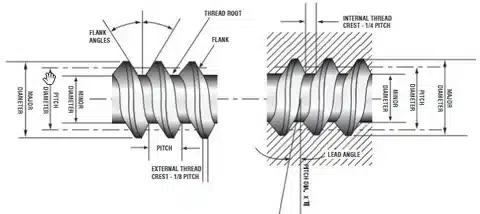

Crest: The uppermost surface of the outer thread or the bottom of the inner thread groove isthe crest.

Root: is the reverse – the bottom of the external thread, or the top of the internal thread groove.

Flank: joins the crest and root to create the load-bearing surfaces where external and internal threads come into contact.

Thread Angle is the angle between the flanks that are included, which is usually either 60 degrees (metric) or 60 degrees (unified), depending on thread type.

Pitch is the distance between similar points on the successive threads.

Lead is the axial movement of each full revolution (pitch with single-start threads).

The thread size is characterized by the three critical diameters: Major Diameter (the largest diameter of the external thread), Minor Diameter (the smallest diameter of the external thread), and Pitch Diameter (the theoretical diameter of the thread at the thread thickness equals the groove width). Of all measurements related to thread functionality, pitch diameter is probably most significant.

B. Fit & Tolerance Insights

Classes of threads identify the tightness of threads with each other, which directly influences the ease of assembly and strength of the joints. Classes 1A, 2A and 3A are used externally and classes 1B, 2B, and 3B internally.

Class 1 is the most loose in that they can easily assemble with slight imperfections or coating. Class 2 is the general-purpose standard and has a trade-off between a convenient assembly and sufficient precision to suit the general task. Class 3 provides the smallest tolerances in high-precision assemblies where the highest strength and accuracy are a requirement.

Bolt thread terminology classifications will assist you in specifying the correct fit in every application. The precision of aerospace fasteners is normally Class 3, whereas cost-effective and fast-assembly construction may be Class 2.

C. Thread Standards & Forms

Unified Thread Standard (UTS) controls North American applications, where general use is UnC (Unified Coarse), whereas applications that demand greater strength or finer walls use UnF (Unified Fine). Metric threads are based on the ISO standards and can be found across the world, with the advantage of providing rational sizing in millimeter units.

Special types are Whitworth threads (British standard 55 angle), UNR threads (unified with rounded roots to resist fatigue), and UNJ threads (aerospace usage with obligatory root radius). Each standard was developed to fulfill industry requirements to be strong, to be manufactured or to be international.

Why It Matters: Real-World Impacts

The right thread choice in industries averts disastrous failures. The aircraft engines take UNJ threads since the rounded geometry of their roots withstands fatigue cracking during constant vibration and thermal cycling. Use the wrong thread form, and the failure of the component ensues at 30,000 feet.

To hobbyists and small-scale machinists, the knowledge of these terms would save time, as well as materials. Scrapped parts are avoided when the difference between pitch and lead is known when writing CNC threading cycles. Identifying thread classes’ requirements will assist you in precision mold components that fit the first time and not necessitate reworking.

Quick Reference Tools

Essential Terms Cheat Sheet:

- Pitch Diameter: This is the most important measurement of thread fit.

- Thread Class: Establishes tolerance and assembly properties.

- Major/Minor Diameter: Spell out thread envelope dimensions.

- Thread Form: Strength and Suitable Application.

- Pitch vs Lead: Pitch where single start, Lead where multi start threads.

Common Thread Comparison:

- UNC: Rough threads as a general assembly threading, faster threading.

- UNF: Thin wall, fine, greater strength applications.

- Metric: Logical sizing, international standard, very fine in accuracy work.

- Acme: Trapeze shape to receive power and place it.

Keep in mind these two important considerations: the pitch diameter will either cause the threads to assemble correctly or not, and the thread class will determine the cost of manufacturing and the accuracy of assembly.

Conclusion & Takeaway

These 36 thread terminology concepts can convert confusion to clarity, whether it be in CNC machine programming, specifying fasteners, or troubleshooting an assembly problem. This literature enables dialogue with suppliers to be precise, specifying parts to be correct and the outcomes of assembling to be reproducible, regardless of the threading use.

Wish you could be poking your threading in the future? Order our complete threading reference chart, which provides an overview of all these terms in a conveniently installed format that would look great in your workroom or design work-table. Place this guide on your desk and distribute it to your team members and your threading work would be more successful and anticipated.

What is your largest threading problem? Write a comment and we will see. Whether it is metric conversions, tolerance stackups, or thread forms, we are all the better as a machining fraternity when we share information and we learn through the experiences of others.