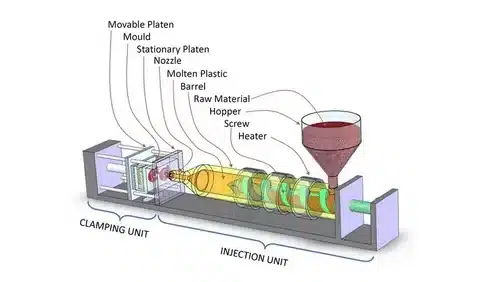

Introduction: Understanding Injection Molding

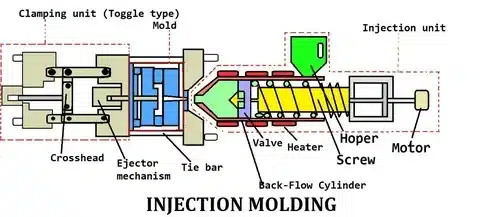

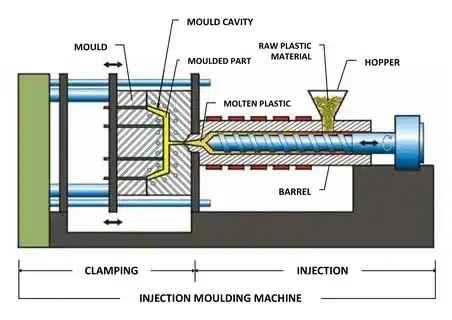

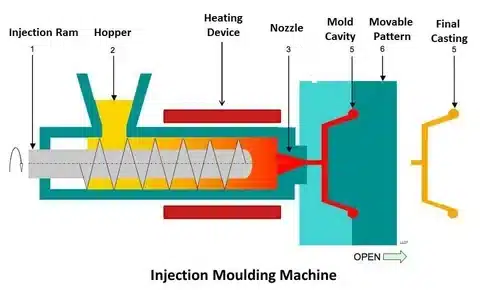

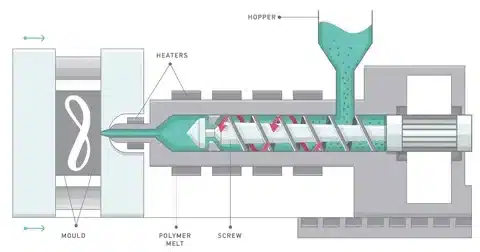

The manufacturing process, which enables the creation of high-precision plastic parts with extremely high consistency and efficiency, is injection molding, and it is one of the most diverse and widely used processes in the modern industry. In this type of thermoplastic forming process, the molten thermoplastic is injected through a mold cavity that has been designed to fit that shape; the molten thermoplastic cools and solidifies to that shape. The contribution of injection molding in the contemporary manufacturing industry cannot be underestimated since it has been used in the automotive, electronics, medical equipment, and consumer products industries.

The development of injection molding technologies has introduced specialized methodologies to deal with particular manufacturing issues, whether it is the development of ultra-thin walls or the use of two or more materials in a single part. It is important to know all these injection molding technologies in order to enable manufacturers to optimize their production processes and to obtain better part quality.

Gas-Assisted Injection Molding: Enhancing Efficiency

Gas-assisted injection molding is an advanced process in the technology of injection molding whereby pressurized nitrogen gas is used to form hollow areas inside molded components. This is initiated by pouring molten plastic into the mold volume, after which pressurized gas is introduced through special nozzles. The gas forms internal cavities without damaging the structural integrity and finishing of the part.

Gas-assisted molding offers considerable advantages, such as a large reduction in material usage, shorter cooling times, and a lessening of warping or sink marks. The technology is especially applicable in large plastic components, where using the traditional solid molding method would incur high material expenses and time consumption in the cycle time. This method has now been adopted by the automotive sector to produce parts, including door handles, instrument panels, and structural parts, wherein weight savings and material efficiency are of utmost importance.

Gas-assisted injection molding is used ideally not only in car parts, but also in hollow structures in appliances, furniture pieces, and housings of industrial equipment. The process is very good in producing components with thick areas, which, otherwise, would have been affected by cooling failures in the traditional molding operations.

Thin-Wall Injection Molding: Maximizing Speed and Precision

Thin-wall injection molding specializes in manufacturing parts with an average thickness of 0.5mm to 2mm as wall thicknesses, thus needing to monitor injection parameters and mold design carefully. This injection molding technology requires high injection speed and maximized cooling systems to be able to fill the cavity before the material hardens.

Thin-wall molding has superior benefits that make it enticing in high-volume production. The result is a faster cycle time due to the shorter cooling time, and material savings through the consumption of fewer plastics per part. Moreover, the lightweight aspect of thin-wall parts adds efficiency to the products and cost-effective transportation.

Smartphone housing, tablet cases, and laptop parts, where space and weight are essential factors, are high-stakes components of consumer electronics that manufacturers of these products rely on thin-wall injection molding to create. Medical devices are used in disposable syringes, laboratory equipment, and diagnostic device housings that must be precise and cost-effective. This technology also finds great use in the packaging industry in terms of developing lightweight containers and protective packaging solutions.

Liquid Silicone Rubber (LSR) Injection Molding: Versatility in Design

LSR molding is a specialized injection molding technology that is aimed at working with liquid silicone rubber. This is done by combining two-component liquid silicone rubber systems that cure by platinum-catalyzed addition reaction, forming parts that are remarkably flexible, durable, and withstand high temperatures.

LSR molding advantages can be seen in high precision in complex geometries, high biocompatibility when used in medical applications, and high chemical resistance. The silicone after treatment retains its characteristics at extreme temperatures, ranging between -65 °C and +200degC and is suited to harsh applications. The inherent flexibility of the material enables elaborate designs that have thin parts and undercuts that cannot be achieved in rigid thermoplastics.

The biggest field of LSR molding is medical device production, such as surgical instruments, implantable parts, and diagnostic equipment, in which the biocompatibility factor plays a vital role. The automotive uses include seals, gaskets, and vibration dampeners, which need to withstand the high temperatures of use. LSR is also used in the baby product industry to mold pacifiers, bottle nipples, and teething toys, and is exploited due to its safety and lifetime characteristics.

Metal Injection Molding (MIM): Precision in Small Metal Parts

Metal Injection Molding represents a union of plastic injection molding in design flexibility and the strength and durability of metal components. It is a niche injection molding process that entails the incorporation of finely powdered metals with thermoplastic binders to form a feedstock that can be molded in terms of traditional injection molding apparatus. It goes through the debinding and sintering stages in which the molded parts are debinded and the metal particles sintered into dense and robust parts.

MIM has great benefits in producing small, complex metallic pieces that would be hard or costly to create using conventional machining or casting. The technology provides a cost-effective layout of complex geometries with small tolerances, thus suitable for high-volume manufacture. Components can be produced with densities of 95-98 percent of wrought material properties and with dimensional accuracies of +-0.3- +-0.5.

Manufacturers of electronic items use MIM to make connector pins, heat sinks, and magnetic parts in which accuracy and dependability are paramount. This technology is used in the automotive industry in fuel system parts as well as transmission parts, and engine parts that have high strength-to-weight ratios. Turbine components and brackets, as well as fasteners, are aerospace applications in which the material properties and dimensional accuracy play a role in safety and performance.

Overmolding and Insert Molding: Combining Materials for Enhanced Functionality

Overmolding and insert molding are high-technology injection molding processes in which several materials or components are over-injected to create one finished part. Overmoulding is the process of coating an already moulded substance with a second material, producing parts with better functionality, ergonomics, or aesthetics. Insert molding entails the embedding of metal parts, electronic components, or other materials directly into the plastic part as part of the molding process.

These methods have many advantages, such as better product ergonomics with soft-touch surfaces, better durability with materials that have merged the powers, and less assembly effort since many different parts are combined into one. The final products usually have better performance characteristics than individually manufactured and assembled components.

Another typical use of overmolding is in tool handles, whereby a hard plastic core is overmolded with a soft elastomer layer to enhance its grip and comfort. Connector applications are using insert molding to imprint metal contacts into plastic housings, where they provide dependable electrical connections, and the assembly processes are made easier. The manufacturers of consumer goods use such technologies in the production of products with electronic components or decorative or functional functionalities that would have been beyond reach without the use of single-material molding.

Choosing the Right Injection Molding Technology

When choosing the right injection molding technology, one must not only place special attention on the choice of the material and on the characteristics of the part to be filled (in particular, its complexity and cost) but also consider the volume of production needs and the cost limitations. The choice of material used will usually dictate the type of molding that is possible with the special process, such as LSR molding, or MIM will only use certain material systems. Part geometry and complexity determine whether various methods can be used, with methods such as gas-assisted molding being best in large, thick parts and thin-wall molding in lightweight parts with high volumes.

Volume of production is also important in the choice of technology because certain methods are economically more effective when used in large volume productions, whereas other methods may be more effective in prototyping or low volume productions. The cost analysis must also include tooling and processing costs and also the material costs, cycle time, and post-processing requirements. The selection criteria are further reduced by quality requirements and performance specifications, especially in those applications where performance standards are regulated, e.g., medical device or aerospace.

The cooperation with seasoned molding experts and the careful feasibility research might contribute to the selection of the most appropriate technology to be used in particular applications. Development and testing of prototypes can be highly informative with regard to the behaviour of various methods before engaging in full scale production.

Conclusion: Advancements in Injection Molding Technologies

The variety of the existing injection molding technologies proves the impressive development of the basic manufacturing method, and each of the techniques has its own advantages to be applied in particular situations and industries. Whether it is the efficiency in materials in gas-assisted molding, the dimension of precision of thin-wall injection molding, the range in LSR molding, or the strength of MIM processes, these technologies have pushed the limits that are available in the manufacturing industry.

Overmolding and insert molding have integration capabilities that increase the design options and allow the development of complex multi-material components that are capable of satisfying more complex performance specifications. These hi-tech injection molding technologies will become more relevant to providing novel solutions to industries as manufacturing requirements keep changing.