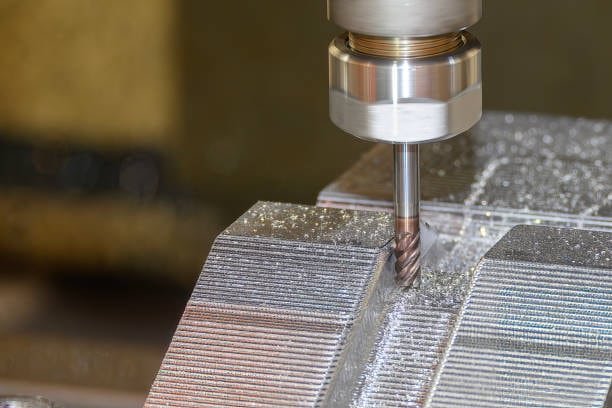

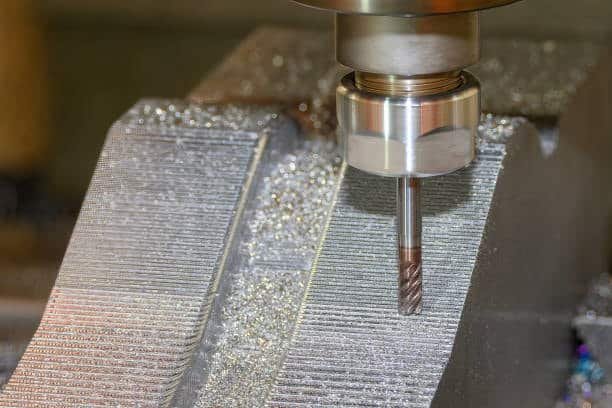

Companies use milling cutters more than any other manufacturing process because of its ability to serve many operations. Through this subtractive manufacturing method the milling technique improves our ability to produce precise parts across multiple sectors. This complete manual explains all mill types and their features and shows how they adapt to stronger industrial needs.

What Is Milling?

Through rotary action milling tools cut away material from the workpiece at specific feed directions. The tool rotates against the workpiece and produces chips during the removal of material. The difference from turning is that milling holds the workpiece as it stays fixed but the tool moves in multiple directions through rotating.

The History and Evolution of Milling

Eli Whitney introduced the first milling machine in 19th century history during early development. The technology behind milling has developed extensively since its first appearance. Hand-driven milling tools have developed into advanced computer-controlled CNC milling equipment which makes precise micro dimensional parts and shapes rotating cutter.

In the late 20th century CAD/CAM systems changed milling operations because they made machines produce elaborate pieces without much human assistance. Today’s milling equipment runs five or more directional programs to produce exceptional product details.

Conventional Milling vs. Climb Milling

To explain manual milling machine types you need basic knowledge about two essential cutting procedures.

Conventional Milling (Up Milling)

In conventional milling, the cutter rotates against the direction of the feed. This approach has several characteristics:

- The first tooth in the cutter engages the material when chip thickness is shortest and builds up as the cutter moves.

- The cutting forces generated by this method push the workpiece upward so durable clamping methods are necessary.

- The resulting surface quality from climb milling is better than conventional milling.

- Although it produces warmer temperatures the tool stays intact longer

- Machines with backlash problems or materials featuring hard surface scales work better with this strategy

Climb Milling (Down Milling)

The tool spins in match with the tool’s moving direction during climb milling. Key characteristics of the rotating cutting tool include:

- When the cutting tooth begins the cutting cycle it reaches its maximum chip depth before moving downwards as the cutter spins.

- When pressuring down the material during milling operations the cutter locks in place and helps secure it in place

- Produces superior surface finishes

- Requires machines with minimal backlash

- Modern CNC machines mostly use this method of operation

- The process yields faster cutting while adding strain to tools in some tasks.

Classification by Machine Configuration

Horizontal Milling Machines

Horizontal milling machines have cutting tools that spin at their base because their tool holding spindle is arranged horizontally. The horizontal setting provides multiple benefits.

- Excellent chip evacuation due to gravity

- Superior for heavy-duty cutting operations

- This type of milling machine delivers perfect results when machining flat surfaces plus slots and grooves.

- The system has gear cutting and similar operation features through arbor-mounted cutters.

- The machine keeps its shape when dealing with big pieces of material

- This machine type runs well in manufacturing scenarios that demand fast material reduction.

Vertical Milling Machines

A vertical milling machine comes with its spindle positioned vertically. The spindle moves straight down from the machine to the worktable. Key features include:

- Better visibility of the cutting operation

- The machine becomes easier to use for advanced contour milling tasks

- Simpler tool changes

- This tool performs well during face milling jobs plus drills and plunging cut tasks

- People in machine and tool-making facilities use this type of machine because it handles many work styles effectively

- Available in bridgeport-style configurations for manual operation

- The machine type serves multiple CNC tasks to make different types of parts

Gantry Milling Machines

Gantry milling machines have an elevated bridge design that reaches across the work surface area. This design offers:

- The machine setup handles big parts with its extended work area.

- Our design offers strong support to ensure accurate machine processes

- The machine finds widespread use as a tool to create products for aerospace manufacturers and the automotive industry plus large components.

- Available in both three-axis and five-axis configurations

- Excellent accessibility around the workpiece

- Capability to machine very large components like aircraft structural parts

Bed Mills

The work table moves beneath a stiff stationary spindle. Characteristics of various machining operations include:

- Rigid construction for heavy cutting operations

- Its working area has distance restrictions.

- Particularly stable for precision work

- Bed mills serve many purpose areas including toolroom work and manufacturing processes

- These machines produce accurate results on small-scale parts projects

Classification by Number of Axes

3-Axis Milling

The tool travels simultaneously along three pathways known as X, Y, and Z movement. These machines:

- Can machine most standard geometries

- These equipment types handle everyday machine shop work.

- Most machine shop industries use this setup type as their standard equipment.

- They offer both adaptable use and reasonable price ranges for different operations

- They have a basic design that makes them easier to program and handle than multiple-axis systems.

4-Axis Milling

Most four-axis mills include angular milling movements around their X-axis (A-axis) or Y-axis (B-axis). This configuration:

- Helps the machine process all sides directly with automatic repositioning.

- Machine tools can apply tools to circular workpiece surfaces.

- The system fits perfectly with parts that require angled features.

- Manufacturers use these machines for aerospace parts and healthcare implants alongside advanced engine components.

- The setup delivers better productivity than ordinary 3-axis machining systems.

5-Axis Milling

Five-axis milling machines use three-dimensional movements plus two rotating motions. These sophisticated machines:

- The machine system reaches any spot on the workpiece easily from multiple angles.

- The set-up process for complicated parts takes one run instead of many.

- These machines generate smoothly shaped surfaces with fine polishing quality.

- Significantly reduce fixture requirements

- The use of short cutting tools helps improve both tool strength and accuracy.

- Turbo engines and health devices depend on them for successful operation.

- Milling machines of this type lead all other equipment in making complex parts

Multi-Axis Milling

Specialized milling devices now include configurations beyond five axes that feature rotational and linear extra movements. These machines:

- Enable ultra-complex part production

- These milling tools are designed exclusively for aerospace and medical applications.

- A machine can manufacture complex shapes quickly.

- Often incorporate turn-mill capabilities

- They demonstrate the best current machining innovations

Types of Milling Operations

Face Milling

When machining flat surfaces you cut them straight across their ends. Key characteristics include:

- The matching blades exist on both the outer rim and inner base of the cutter.

- The process exists to fabricate smooth flat elements

- Creates high-quality surface finishes

- Tools complete fast work of large excess material removal

- Systems commonly perform face milling tasks at the beginning of production runs.

End Milling

End mills can work both at their face and edge due to their special cutting ability. This versatile operation:

- Creates slots, pockets, and profiles

- The cutter can penetrate material without needing preparation.

- This method requires multiple tool shapes to complete all work tasks.

- Milling machines use this operation for most of their CNC functions

- Using end mills produces precise shapes in designs

Profile Milling

This milling method cuts on the outside part surface to form its outer shape. This operation:

- The operation helps define the outside boundaries of machine parts.

- He uses small end mills mainly for precise corner areas

- Construction of effective toolpaths needs special attention to achieve the best surface quality

- Using this technique forms the main element of parts.

- Different milling techniques can achieve this operation conventionally or with facing into the cutting direction.

Pocket Milling

Partitions are cleaned out to develop internal components. Characteristics include:

- The operation starts with point or helical insertion motion.

- The technique mainly uses trochoidal paths to remove materials efficiently

- Creates recessed areas in parts

- This technique is widely applied in the aerospace sector to produce structural components.

- Users must plan chip evacuation during this specific operation.

Thread Milling

Thread milling builds full threads with its specialized cutting tools while rotating. This process:

- The system builds threads in all work materials with high accuracy.

- Our system makes different thread types through one setup

- The technique gives better thread shaping results compared to regular tapping work on extensive threads

- The process minimizes tool failure during material processing

- Our technique works with blind holes because it eliminates chip control issues

Gear Milling

A machine produces gear teeth by processing specific cutters or gear-making systems. This operation:

- This tool makes different types of gears such as spur, helical, and bevel gears.

- In its manufacturing process the machine often applies either hobbing or form milling tools

- Requires precise indexing capabilities

- Creates complex tooth profiles accurately

- Transmission parts require this operation.

Cam Milling

Cam milling technology makes the specific shapes needed for mechanical cams in mass production . This specialized operation:

- It develops exact cam shapes for mechanical equipment.

- The system needs smooth simultaneous spinning and moving actions.

- The process uses both 4-axis and 5-axis equipment to make intricate shapes

- Automotive power units require this method to operate properly

- The machine builds profiles that switch rotary movement into linear movement and the other way around.

Classification by Cutting Tool Types

Ball End Mills

The ball end mills possess a rounded tip that makes easy transitions across curves. These tools:

- The tool excels at forming regular 3D slope patterns

- These tools form a basic part of mold-making and die production.

- Keep inner curves free from marked edges with this tool

- The system lets you set different cutting depths without forceful jumps between settings

- These cutting tools regularly perform intricate surface machining with 5-axis machines.

Flat End Mills

Flat end mills keep their cutting surface aligned straight across the tool shaft. These versatile tools:

- You can make flat bottom elements through shoulder and pocket features.

- Produce sharp internal corners

- You can use this tool with different flute designs depending on the work material.

- The greatest number of tools uses flat end mills as primary tools.

- Are essential for general-purpose machining

Bull Nose End Mills

Bull nose end mills bring together flat and ball end mill characteristics by having a rounded straight edge. These tools:

- These edges deliver better durability than plain angled areas

- The tool produces round transitions between touching surfaces.

- The rounded shape helps this tool last longer because it reduces the areas where the stress builds up

- This tool produces effective results between the features of flat and ball end mills.

- They perform well for regular machine tasks.

Tapered End Mills

These mills become thinner in diameter towards their pointed tip. These specialized tools:

- Determine angled designs for shaped parts in casting processes

- The equipment helps machines cut deeply into tight spaces.

- Tools benefit from greater hardness because they contain no straight sections

- These tools are necessary for producing mold and die components.

- These tools enable you to make deep cuts using small cutting heads.

Indexable Tools

The milling tools of this system feature replaceable cutting inserts. These economical tools:

- The tool system design enables fast replacement of the tool’s blades without changing the whole unit.

- Grant customers selection from many insert choices for processing various materials

- Excel at heavy roughing operations

- The tool reduces production expenses when making many parts

- The tool system delivers fast cutting performance

Specialized Milling Processes

High-Speed Milling (HSM)

The technique of high-speed milling runs at faster rotatory speeds and feeds than regular millers do. This approach:

- The method produces less force during cutting which leads to smaller chips.

- Improves surface finish quality

- Increases productivity dramatically

- Often uses specialized balanced tooling

- The process demands strong machine parts that need an advanced control system.

- It has transformed the production of molds and dies through modern methods.

High-Efficiency Milling (HEM)

High-efficiency milling system designs toolpaths to keep the cutting tool engaged properly. This strategy:

- Maximizes material removal rates

- Extends tool life significantly

- Reduces heat generation

- The tool touches all parts of the flute during operation

- Creates more consistent cutting conditions

- The process mainly uses trochoidal and dynamic tool paths

Micro Milling

Mechanical tools cut at microscale levels. This precision process:

- Our tools have the finest diameter at 0.001 inches for precise cutting.

- Makes small-scale features for healthcare and electronics products

- Requires specialized high-speed spindles

- Demands exceptional machine rigidity and vibration control

- Miniature component making depends heavily on this method.

Plunge Milling

A series of vertical plunging actions is used to strip out material during plunge milling. This technique:

- Minimizes lateral cutting forces

- This technique delivers outstanding results in machines that weak when compared to competing options.

- The approach especially suits pocket removal in deep cavities

- Reduces tool deflection

- Is effective for difficult-to-machine materials

Trochoidal Milling

When using this cutting motion the milling tool makes circular movements while advancing forward. This advanced strategy:

- Maintains constant tool engagement angle

- Significantly reduces cutting forces

- Enables much higher feed rates

- Extends tool life dramatically

- The technique brings optimal benefits when cutting slots.

Material-Specific Milling Considerations

Hard Milling

When a machine cuts through materials stronger than HRC 45 levels it performs hard milling. This challenging process:

- Often replaces grinding operations

- Uniform performance needs tools made from coated carbide or ceramic materials.

- The system needs higher rotational speeds and reduces feed rates from basic milling practices.

- Demands rigid machine construction

- This technology has totally upgraded how mold and die makers produce work.

Aluminum Milling

The aluminum milling process helps producers find ideal setup values for their non-ferrous metal. Key considerations include:

- The cutting speed for aluminum operates faster than the rate for steel.

- Our tool design includes specific flute shapes to stop chips from becoming compacted.

- Cooling equipment protects against unwanted material sticking.

- This process sets new possibilities for fast material removal.

- Suitable chip removal systems need special attention in manufacturing processes.

Titanium Milling

The process of titanium milling handles the production issues of working with aerospace quality titanium. Special considerations include:

- Reduction of cutting speed helps control heat production during machining.

- Rigid toolholding to prevent chatter

- Optimized cutting edges help titanium avoid brittleness during production

- Plenty of coolant keeps the cutting tools from wearing out too quickly.

- Specialized coatings for improved performance

Stainless Steel Milling

Special procedures are needed for stainless steel milling because this material tends to strengthen under pressure. Key factors include:

- Maintaining positive cutting geometry

- You need to mill at lower speeds and raise the feed rate compared to other stainless steel processes.

- Ensuring continuous cuts when possible

- Setting up tools firmly to block vibrations from entering the system

- No issues arise from choosing tool coatings that withstand high temperatures

Composite Material Milling

The method solves specific design issues in products made from fiber-reinforced materials. Important considerations include:

- Special tools must have designed shapes to block material chips from separating

- Dust collection systems for health and safety

- Sharp compression tools enter and exit the material without leaving residue

- Companies handle wear problems with their cutting tools

- Setting up trimming patterns that safeguard against heat injuries

The Role of CNC in Modern Milling

Machines with Computer Numerical Control (CNC) have made milling a modern automated process that replaces the manual methods of earlier times. CNC machining services now offer comprehensive solutions for precision manufacturing across all industries. Modern CNC milling machines:

Our CNC machining system processes complicated paths designed from CAD files

The production system maintains exact machining standards each time it runs.

Operate with minimal human intervention

Integrate with production planning systems

Our system has enhanced simulation tools to protect your equipment from collisions.

Incorporate in-process measurement systems

Setting up production without human monitoring helps to boost factory output.

Advanced Milling Technologies

Multi-Task Machining

Multi-task machines run both milling and turning operations on a single machine platform. These hybrid machines:

- The process flow needs fewer changes between steps.

- A single machine setup machinens complete components.

- Join different machine platforms into a single system design

- Machining tools achieve better shape precision since they need fewer operations.

- Today these systems see more usage when creating high-cost components.

Additive-Subtractive Hybrid Machines

Advanced machines unite additive production and precise cutting techniques for new solutions. This hybrid approach:

- The technology lets us make internal product designs that standard machine tools cannot produce.

- Allows for optimized material distribution

- A hybrid machine uses less materials than the standard subtractive manufacturing process

- The technology produces fresh design solutions by uniting production methods

- Manages multiple manufacturing approaches in a single process

Ultrasonic-Assisted Milling

Something other than traditional milling provides vibration at high frequencies while operating the machine. This technology:

- Ultrasonic vibration methods make it easier to cut through ceramic and glass materials.

- Reduces cutting forces significantly

- Machining equipment lasts longer when working with hard materials

- The process cuts better with less edge breakage.

- The method lets us machine materials that could not be worked with regular tools before.

Industry Applications of Milling

Aerospace Milling

Together with slab milling and other advanced techniques the aerospace sector depends on milling processes to manufacture essential component parts plain milling. Key applications include:

- Specific components need strong materials that weigh little

- Complex turbine and compressor components slot milling

- The landing gear parts need to bear strong mechanical properties during service

- Thin-walled lightweight structures

- Our services cover the production of titanium and nickel alloys with unique materials.

Medical Device Milling

Manufacturing medical devices depends on exact milling processes to make essential parts that affect lives. Applications include:

- Orthopedic implants with complex organic geometries gang milling

- Surgical instruments requiring precise functionality

- Dental prosthetics with custom fit requirements

- Medical device housings with demanding tolerances

- Milling technology defines small parts for small-scale medical instruments.

Automotive Milling

Manufacturing facilities in the automotive business use milling methods for both prototype testing and product development stages.

- Engine components requiring precise tolerances

- Transmission components with complex geometries

- Manufacturing businesses use milling tools to make part molds for commercial production.

- Custom components for racing applications

- Prototype parts for design validation

Die and Mold Making

The production of dies for manufacturing tools demands millers operate at their highest level of performance form milling cutter. This sector requires:

- Special surface treatments reduce polishing requirements

- Complex 3D contoured surfaces

- Hard material machining capabilities

- This engineering process removes deep material sections while keeping cutting tools straight

- High precision for proper part fit and function

Environmental Considerations in Milling

As part of industry development modern milling operations achieve better environmental results by implementing these measures.

- Minimum amount of lubrication helps lower the need for coolant during this process

- Dry machining techniques where appropriate

- Energy-efficient machine designs

- Our system designs tool paths that need less power energy

- Reclamation and recycling of metal chips

- Improved tool lifespan happens when burners use their ideal cutting methods

- Reduced waste through simulation and collision avoidance

- Future Trends in Milling Technology

Future Trends in Milling Technology

Current milling technology will develop in several directions according to recent research.

- Increased automation and lights-out manufacturing

- Computers use artificial intelligence to manage the best cutting actions

- Input monitoring tools watch production process changes while control systems react automatically.

- Integration with digital twins for predictive performance

- Manufacturing teams will develop better ways to combine production methods

- Researchers continue developing new tool materials and surface layers.

- Increased precision at higher production rates

Conclusion

Milling exists at the place where engineering materials science and computer control technology converge. Modern manufacturing standards demand better milling technologies that let us produce parts today that were unthinkable less than 30 years ago. Today’s manufacturing technology shows its worth as milling machines produce high-quality medical imports and light materials for aerospace and automotive industries. The milling industry will keep making progress using digital systems and hybrid technologies to produce materials beyond our current manufacturing limits.