Introduction: The Ubiquity of Plastics

The fabric of our everyday life has been plastic because it is found in the smartphone you hold in your hand and the car you drive. Such universal polymers create the objects of life, like medical equipment and automobile components, and our current world would be inexplicable without this versatility and such a high variety of properties.

Knowing the various plastic types is not merely a learned concept but a necessity in making quality choices in terms of manufacturing, sustainability, and simple product purchasing. Wondered why you can melt some plastics down and use them again and again, and why other kinds of plastics harden once created and cannot be melted again? The solution can be found in their basic molecular structure and thermal properties that predetermine their use in the industries of precision production, up to consumer goods.

What Are Plastics?

Plastics are synthetic polymers which are filled with long carbon chains and can be made to shape or form into virtually all shapes and forms. These versatile materials are a combination of repeating molecule units known as monomers that form long-chain polymer networks that have remarkable plastic properties.

Plastics have such versatility because they can be designed to have certain properties- flexibility to rigidity, transparency to non-transparency, and chemical resistance or conductivity. This flexibility has seen them spread to many industries, encompassing accuracy connectors to the most common household products.

Studying plastics involves the classification of materials in terms of physical and thermal behavior. The major classification system separates plastics into two basic groups: thermoplastics and thermosetting plastics, with unique molecular structure that defines their processing techniques, applications, and recyclability.

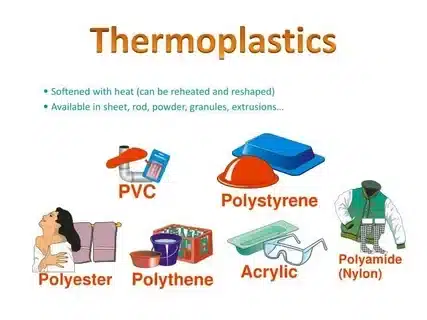

Thermoplastics: Reversible and Recyclable

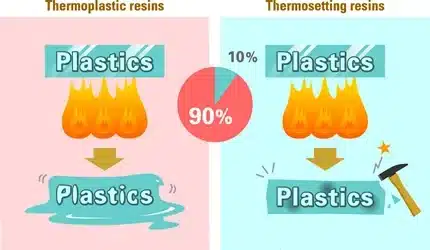

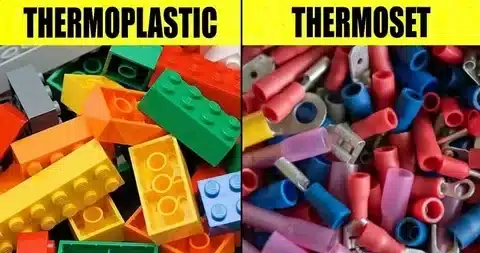

Definition: Thermoplastics are melting polymers that can be reshaped several times without the decomposition of the material into chemical components. This makes them very useful in the recycling of plastic and in sustainable manufacturing efforts since it is a reversible process.

Examples: Typical thermoplastics are:

- PVC (Polyvinyl Chloride) is used in pipes and electric cables.

- Nylon – crucial to textiles and accuracy.

- Polyethylene (Polythene ) – Polyethylene is used extensively in packaging.

- Polypropylene – automobile components and containers.

- ABS (Acrylonitrile Butadiene Styrene) – consumer electronics housings.

Properties: Thermoplastics have unusual properties because of the structure of their molecules:

- Weak intermolecular forces between polymer chains. Linear polymer chains or branched polymer chains.

- Heats up and can be softened, which makes it possible to reshape and form.

- Stiffens as it cools and still keeps its new shape.

- Outstanding injection molding and extrusion.

- Adjustable crystallinity with respect to transparency and strength.

Applications: Thermoplastics are especially useful in a wide variety of industries:

- Flexibility and barrier property of packaging materials are needed.

- Goods required by consumers are durable and beautiful.

- Car components that require accuracy and toughness.

- Medical equipment in which sterilization and biocompatibility are paramount.

- Connector parts that need dimensional stability and electrical qualities.

Recycling: Thermoplastics are highly effective in recycling processes of plastics because of their capability to melt and reform. This trait enhances sustainability by minimizing waste and saving resources, and therefore, it is the choice of manufacturing that is concerned with the environment.

Thermosetting Plastics: Permanent and Durable

Definition: Thermosetting plastics. Thermosetting plastics are defined by being chemically irreversible in their response to heating, so that once it has been heated, they form a rigid, networked structure that cannot be remelted or re-shaped once hardened. The result of this irreversible change is the production of materials that have high levels of durability and performance.

Examples: Important thermosetting materials are:

- Bakelite – the first synthetic plastic, and it was also used in electricity.

- Melamine – domesticware and laminates.

- Resin materials: epoxy resins – adhesive, composite material.

- Polyurethane – foams, insulation, and flexible.

- Phenolic resin – brake pad and electrical parts.

Properties: Thermosetting plastics have properties due to their cross-linked structure:

- Three-dimensional polymer networks are heavily cross-linked.

- Once cured cannot be remelted or reshaped.

- Outstanding thermal stress dimensional stability.

- Excellent chemical and mechanical resistance.

- Minimized creep and high long-term performance.

Applications: The thermal set permanence of thermosets renders them best suited to challenging applications:

- Heat-resistant electrical switches and insulators.

- Floor tiles that require resistance to chemicals and durability.

- Thermally stable kitchenware that ensures food safety.

- Aerospace parts that demand low-weight strength.

- Components needing high-dimensional accuracy. Precision mold components are where dimensional accuracy matters.

Durability: Thermosetting plastics have excellent heat and chemical, and mechanical stress resistance. Their cross-link structure offers superior long service life under harsh conditions and hence cannot be avoided in high-performance applications and precision manufacturing.

Comparative Overview: Thermoplastics vs. Thermosets

| Property | Thermoplastics | Thermosetting Plastics |

| Reusability | Can be melted and reshaped multiple times | Cannot be remelted once cured |

| Molecular Structure | Linear/branched chains with weak bonds | Cross-linked 3D network structure |

| Heat Resistance | Softens with heat application | Maintains rigidity at high temperatures |

| Recyclability | Easily recyclable through remelting | Difficult to recycle, limited options |

| Processing | Injection molding, extrusion | Compression molding, transfer molding |

| Common Applications | Packaging, automotive parts, containers | Electrical components, adhesives, and composites |

| Cost | Generally, lower processing costs | Higher initial costs but longer lifespan |

| Flexibility | Variable from rigid to flexible | Typically rigid with limited flexibility |

The comparison shows why the choice of materials is conditioned by concrete application challenges, considering the two in a balanced relationship, such as recycling ability, performance, and production limitations.

Recycling and Environmental Impact

Plastic recycling cannot be overemphasized in the fight to establish green manufacturing practices and their impact on the environment. Although thermoplastics are highly recyclable due to their capacity to be melted and reformed to new set of products, recycling of plastics offers opportunities as well as challenges.

Thermoplastics are the leaders in the sphere of sustainable production due to the possibility of undergoing numerous recycling operations without any significant deterioration of their properties owing to their molecular structure. The availability of sophisticated sorting and chemical recycling technologies is broadening opportunities in recovering valuable materials as a part of post-consumer waste streams.

Thermosetting plastics, however, pose major problems to recycling processes because they are cross-linked. When cured, such materials cannot be remelted, and this restricts conventional mechanical recycling. New technologies, such as breaking down using chemicals, energy conversion, and the inclusion in composite materials, are coming up as a solution.

The industry is coming back with impressive innovations of biodegradable and recyclable plastic substitutes. Compostable materials, bio-based polymers, and new technologies in recycling are reinventing our attitudes to plastic properties and ecological responsibility. This is only at the start of a new era in which high-performance materials and environmental stewardship are moving in the same direction.

Conclusion: Choosing the Right Plastic

Knowing the basic differences between thermoplastics and thermosetting plastics enables informed decision-making in manufacturing, design, and environmental concerns. Thermoplastics are flexible and can be recycled, and also processed at low costs, which makes them the best materials in situations that call for flexibility and sustainability. Greater heat resistance, dimensional stability, and superior durability are achieved with thermosetting plastics, which are necessary in demanding precision applications and long-term performance requirements.

These plastic properties will be determined by certain application requirements, such as thermal requirements, mechanical requirements, recyclability requirements, and performance requirements. As the industries are progressing towards sustainable operation, the choice of the type of plastic materials comes into the fore, as a way of balancing between performance needs and the environment, and promoting responsible use in addition to creative recycling methods to contribute to the future of our planet.