Shaping metals through turning involves rotating the material while a cutting tool removes material for production purposes. Through basic manufacturing operations this process makes accurate cylinder-shaped products used across automotive and aerospace businesses. Different types of machine turning techniques work effectively for targeted uses and demonstrate unique setup methods with special tools and end results. This article explains the basic types of turning operations plus their useful applications and benefits, including the production of a machined component, to serve experts and beginners.

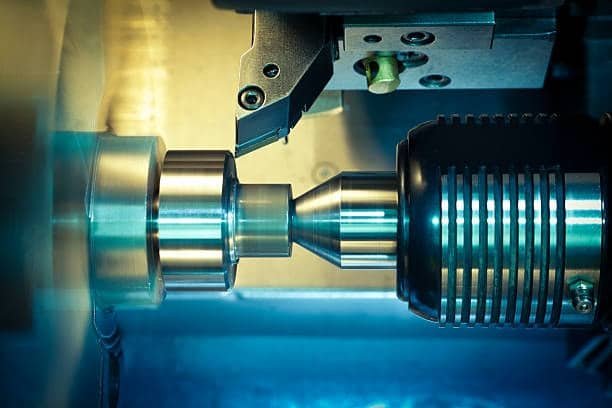

Straight Turning

To make a regular cylinder from a rotating piece material is removed straight through its outer surface. By pushing parallel to the workpiece’s main axis the tool reduces its diameter as required. This method produces shafts pins and other cylindrical parts at industrial facilities. General machining depends on straight turning because this basic method brings both easy operations and tight measurement results, ensuring a good surface finish . You need proper control measures to stop both tapering and surface defects from forming.

Taper Turning

You make conical parts when the tool reduces workpiece diameter progressively from start to end. You can set the rake angle of a cutting tool or move the tailstock in order to form an inclining surface. Taper turning plays a vital role in machine spindle and tool holder production along with pipe fitting creation because conical shapes enhance component fit reliability. A correct taper result depends on accurate mathematical planning and sometimes more than one tool pass to hit the desired shape. The process works perfectly in sectors that depend on making unique manufacturing parts.

Facing

During the facing operation a tool creates an even flat area at the workpiece’s end. A straight moving tool removes material from the end of a workpiece to make a level striking surface. Facing starts all machining processes by creating a base surface for other machining steps. Facing technology lets us achieve flatness in flanges, gears and bearing applications. The process gives precise measurements but needs right tool positioning to make surfaces smooth across their entire width.

Grooving

To obtain perfect seals and O-ring placement or snap rings the machine operator cuts shallow grooves into the workpiece surface. An exact grooving tool enters the spinning material from its main direction to form the designed space. The manufacturing of pistons and valve bodies depends on groove creation to achieve proper sealing and part locking. The cutting tool needs total accuracy to deliver the correct depth and size of grooves since small errors ruin component performance, and the cutting speed must be optimized .

Parting

The parting process breaks apart a completed component from the raw stock material or metal bar. The thin cutting edge makes radial cuts through the workpiece until it divides completely. High-volume production relies on parting to cut many identical parts from one material piece. To avoid tool damage and excessive tool wear, which can occur due to frequent tool changes, you need to choose the right tools and set the feed rate properly. When parting operations work effectively they help manufacturers produce more items.

Thread Cutting

Thread cutting develops rotating lines called threads to help fasten or move components. The cutting tool moves through a planned route at each rotation step to produce threads with exact dimensions. This method provides high-quality threads in products that need threaded connectors. Thread cutting needs precise equipment and unique multipoint cutting tools since thread failure can result from making mistakes. Many industrial operations need threads in products and use this method for accurate connection.

Knurling

Tools with rounded knurls create diamond or straight surface textures on workpieces which improve grip and appearance. A hardened rolling device makes marks on the rotating material as it presses tightly to create the desired surface texture. Tools with knurling patterns experience better handling because they receive this surface treatment on tool handles, knobs, and fasteners, compared to manual turning methods. Through watching tool pressures this procedure safeguards against damage to the material and tool breakdown.

Form Turning

The form using turning method lets you produce intricate profile shapes on the material through a tool’s unique structure. When using this tool system the shape of the cutting part determines the final form of the finished product rather than standard lathe operations thin layer. Engineers use this process mainly for producing turbine blades and decorative items that need one-of-a-kind shapes, often requiring additional machining processes . The process of form turning helps save time when making complex geometries but needs accurate tool selection and assembly setup tapping tool.

Boring

The boring process expands and polishes holes in a workpiece to create better dimensional precision or surface texture. The operator feeds a mounted bar boring tool into an existing hole of a rotating workpiece with a lathe. Internal cylinder and bearing housing components depend on this method for exact diameter production. An accurate boring process needs strict installation methods and running positions to prevent instrument movement desired diameter.

Contour Turning

The shaping process uses CNC controls to turn irregular surface designs in machine tools. This method creates perfect shapes for aerospace parts and medical implant workpieces. Contour turning creates perfect results at any shape because computer control powers its intricate movements. High-level technology and programming knowledge are needed to make this machining operation reach its maximum efficiency and precision rotational features.

Eccentric Turning

In eccentric turning the lathe spindle template alignment with the workpiece produces revolving components like crankshafts and camshafts turning tools. The technique needs special clamping systems and careful consideration of the side rake angle to properly position the workpiece outside the turning axis. Manufacturers need to master eccentric turning for automotive and machine parts but finding the right set-up and operating skill proves difficult due to the complexity of this method longitudinal direction.

Hard Turning

Hard turning machines parts made of hard materials by using CBN and ceramic-cutting tools for materials with HRC ratings exceeding 45. Hard turning provides a better alternative to grinding and lets machines process intricate parts faster with one operation, especially when using high speed steel tools relief angle. Hard turning serves purposes such as processing gears, shafts, and bearing races, ensuring uniform wall thickness and delivering remarkable precision in surface quality fixed axis. Durability of tools and equipment needs to be strong because of heavy pushing forces during this operation various turning operations.

Step Turning

The step turning process builds several shaped levels along the entire workpiece length to produce a series of concentric cylinders. The tool takes away material in multiple stages until it reaches the required step sizes. This method produces components, particularly tubular components, that need several rounded sections for their functional design. You can easily perform step turning if you organize your setup well.

Reverse Turning

New processing techniques work against the normal turning direction which helps handle material characteristics and tool life behaviors. This method works for particular alloy types or unique tool requirements continuous supervision. Inverting the turning direction helps achieve better surface quality for hard materials yet needs changes to equipment controls and cutting paths cutting tool geometry.

Internal Turning

The activity of internal turning works like boring to shape the inside surfaces of items such as tube or cylinder walls. The tool engages the workpiece to take away materials that create the needed inner shape rough turning. The process helps create precise inner parts of hydraulic cylinders and internal surfaces of gearboxes side cutting edge. You need tightly built tooling equipment and strict control methods to make accurate tools inside limited space.

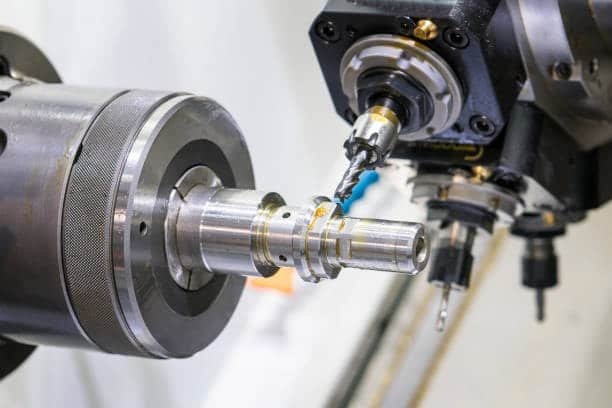

CNC Turning’

The turning process becomes highly accurate and reliable when CNC lathes with computer numerical control technology handle the operation cutting point. A computer controls the cutting tool movement for producing intricate shapes and substantial component quantities cylindrical shape. Different industries use common tools used in CNC turning machines and automatic turning to manufacture turbine rotors and automotive sections. This method produces outstanding results while needing extensive machine and program development costs.

Swiss Turning

A sliding headstock lathe machine with Swiss turning produces parts on a support platform near the tool with little guide bushing space. The specific setup blocks unsupported particles to keep precision high during production of medical screw and watch component workpieces internal and external surfaces. Swiss turning produces precise small parts with exact outer diameter but needs exclusive equipment and expert professionals to run it successfully.

Multi-Axis Turning

Using multiple machine tools in CNC lathes enables the production of complex parts without changing setup. The tool does all three basic operations so manufacturers need fewer machine setup changes plus more precise results. The technology produces exact aerospace fittings and prosthetic parts while optimizing the feed rate and depth of cut. Production operates better when it needs advanced tools and computer programming.

High-Speed Turning

The high-speed turning technique boosts material processing speed while choosing ideal parameters to cut cycle times workpiece material. Advanced machines and tools need to process these parts because they work under heightened stress and heat conditions cutting edge angle. The process delivers top results when making many automotive parts at high speed. Faster metal spinning boosts output but needs suitable tools to avoid deterioration specific cutting force.

Precision Turning

Precision turning creates exceptionally small measurements and smooth surfaces that industries use for aerospace medical and electronics parts. The technology applies advanced CNC equipment with precise tools while following controlled processes. Precision turning makes optics and fuel injector parts without unacceptable faults. Operational success in this machining process of precision turning needs both special skills and strong quality control systems to ensure high accuracy and surface finish.

Micro Turning

Specialized turning machines process small parts with tooling which make particles under 1 mm in size. Milieu healthcare requires this method to manufacture small current connectors and body implants single point cutting tool. The exactness of micro turning needs advanced hardware and specialized tools, along with cluster conditions, which makes it an expert field of manufacturing.

Heavy-Duty Turning

Robust lathes built for high torque handle turbine shafts and ship propellers by turning these large heavy materials. The method removes large amounts of material in energy and marine plants regularly. Large-scale applications need powerful machine tools that meet the high forces during operation to avoid breakdowns.

Conclusion

Turning methods serve many functions in production because they handle both straightforward and advanced parts manufacturing. The turning technique produces outcomes that both healthcare and manufacturing industries can depend on. High-speed turning equipment and CNC technology keep developing to help turning machines produce higher precision work which makes them vital to modern manufacturing development. Manufacturers who grasp these methods know how to improve their operations and serve multiple industries.