Lead times for precision mold components typically range from 2-8 weeks depending on factors like design complexity, required tolerances down to ±0.005 mm, and the extent of verification needed to ensure functional reliability. Unlike off-the-shelf machined parts, these components demand a tailored production sequence that prioritizes accuracy over speed, as even minor deviations can cascade into mold assembly issues or performance failures. Many buyers assume lead time is mainly driven by machine availability, while in reality it is governed by process sequence and quality verification. Lead time for precision mold components is determined by process sequence and verification requirements, not by machining speed alone. Reliable lead times for precision mold components are achieved through controlled production processes, not schedule compression. As a manufacturing planner who’s coordinated tooling projects for automotive and electronics OEMs over the past decade, I’ve seen rushed timelines lead to costly iterations—far better to set realistic expectations upfront. This article maps out the processes and timelines to help OEM mechanical engineers, mold designers, and purchasing managers align their projects with practical manufacturing realities.

Why Lead Times for Precision Mold Components Vary

Lead times for precision mold components vary widely because they reflect the inherent demands of creating high-accuracy parts that must integrate seamlessly into injection molds, where even subtle factors can extend or shorten the schedule. Component complexity plays a central role: simple cylindrical pins might process in 2-3 weeks, but intricate sliders with undercuts or multi-axis features require additional programming and setups, pushing timelines to 6-8 weeks to avoid errors like tool deflection. Tolerance requirements amplify this—ultra-tight specs under ±0.003 mm necessitate slower feeds, multiple iterations, and extended verification, as rushing risks non-conformance that invalidates the entire run.

Quantity and repeatability expectations further influence variability: small prototype batches (1-10 pieces) allow quicker turnaround with manual inspections, while production volumes (50-500) demand fixturing optimizations and statistical sampling, adding days for consistency checks. In my planning experience, these elements aren’t isolated; a complex part with tight tolerances in higher quantities naturally extends lead time, but understanding this upfront prevents surprises and ensures delivery aligns with project needs without quality trade-offs.

Precision Mold Component Production as a System

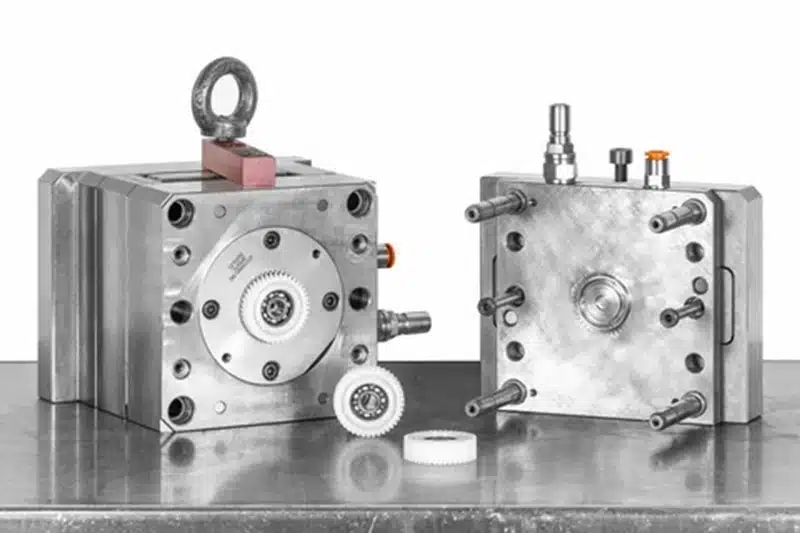

Precision mold component production operates as an interconnected system where each stage builds on the previous, ensuring the final output meets functional demands rather than treating steps as standalone tasks. Machining provides the core geometry, but its outputs feed directly into inspection for validation, which in turn informs any necessary finishing adjustments—disruptions in one area, like inconsistent coolant during CNC, can ripple into delays across the board. This systemic approach maintains traceability: from raw material prep to packaging, every interaction is logged to catch variances early, avoiding rework that could add weeks.

From coordinating multi-supplier projects, I’ve found that viewing production holistically—integrating CAD reviews with shop-floor capabilities—delivers predictable timelines. For those seeking robust systems, exploring precision manufacturing for molds highlights how integrated workflows support delivery consistency, balancing speed with the precision required for long-term tooling reliability.

Key Production Processes That Define Lead Time

The key production processes for precision mold components form a deliberate sequence that anchors lead time, with each step contributing essential value despite varying durations. CNC machining stages—roughing to remove bulk material, semi-finishing for shape refinement, and final passes for tolerance hitting—often consume 40-60% of the timeline, as multi-axis operations on hardened steels require careful programming to prevent vibration-induced errors. Intermediate inspections, inserted after roughing, verify progress and catch deviations early, adding 1-2 days but preventing full-batch rejects.

Secondary operations like grinding for flatness or EDM for intricate details follow, time-intensive due to setup precision but necessary for features like cooling channels that can’t be machined alone. These stages aren’t compressible without risk—rushing grinding might achieve faster output but compromise surface integrity. For a deeper look at these, reviewing production processes for precision mold components provides context on how sequencing optimizes lead times while upholding standards.

Quality Control and Verification as Lead Time Anchors

Quality control and verification serve as non-negotiable anchors in lead time for precision mold components, ensuring outputs meet specs without shortcuts that could lead to field failures. Inspection cannot be skipped or rushed because it confirms not just dimensions but functional attributes like concentricity or hardness, which demand calibrated tools and controlled environments—rushing a CMM scan might save hours but introduce measurement errors up to 0.002 mm. The difference between mere checking (visual scans) and verification (statistical analysis) is profound: verification uses data like CpK to prove process stability, adding time but building confidence.

Sampling accelerates for larger runs—inspecting 20% statistically—but full inspection for prototypes extends schedules by days to cover all variables. In planning reviews, I’ve emphasized that these steps, while time-consuming, prevent costly recalls. Insights from quality control in precision mold components underscore how verification solidifies timelines without inflating risks.

Typical Lead Time Ranges and What They Represent

Typical lead time ranges for precision mold components—2-4 weeks for standard pins or bushings, 4-6 weeks for medium-complexity inserts, and 6-8 weeks for custom sliders—represent a balance of process necessities rather than arbitrary estimates. “Typical” assumes moderate tolerances (±0.01 mm), small-to-medium quantities (up to 100 pieces), and no rush premiums, guiding expectations but adjusting for specifics like material availability, which can add 1-2 weeks for exotic alloys. Quoted ranges depend on assumptions: a 4-week estimate presumes clean drawings and in-stock blanks, but revisions or supply chain hiccups extend it.

Unrealistic expectations, like demanding 2 weeks for tight-tolerance cores, create downstream delays through forced overtime that risks quality slips. From managing electronics tooling schedules, I’ve learned these ranges aren’t promises but projections—contextualizing them prevents misalignment and fosters smoother collaborations.

How Lead Time Stability Affects Injection Molding Operations

Lead time stability in precision mold components directly influences injection molding operations, where delayed deliveries disrupt commissioning and ramp-up, leading to idle machines or rushed validations that compromise startup quality. Consistent timelines allow for phased integration—receiving cores first enables assembly testing—while variability forces workarounds like temporary substitutes that risk inconsistencies. Tooling readiness ties to molding stability: precise, on-time components ensure uniform cooling and ejection, minimizing defects like warpage from misaligned channels.

Unstable lead times amplify costs through extended trials or lost production windows. Connecting this to injection molding quality reveals how predictable delivery supports seamless operations and higher yields.

Common Misconceptions About Lead Times in Mold Component Manufacturing

A frequent misconception is that faster lead times always equate to better service, overlooking how compression often sacrifices verification, leading to hidden defects that surface later. Another: assuming QC and inspection can be skipped to save time, when these steps are integral to preventing rework that ultimately extends overall timelines. Finally, viewing lead time as solely the supplier’s responsibility ignores buyer impacts like delayed approvals or spec changes, which can add weeks through iterations.

These misunderstandings arise from siloed perspectives; holistic views show lead time as a shared outcome.

How OEMs Should Plan Lead Times Realistically

OEMs should initiate early communication of requirements—sharing detailed drawings and tolerances upfront—to allow accurate quoting and avoid mid-process changes that delay machining. Aligning tolerance levels, quantities, and schedules means specifying ±0.01 mm only where functional, opting for batches that leverage economies without overwhelming capacity. Building buffers for verification and potential iterations—adding 10-20% to estimates—accommodates realities like material testing or minor tweaks.

This planning guidance, drawn from joint project timelines, emphasizes collaboration for feasible, risk-managed deliveries.

Conclusion — Lead Time Is a Process Outcome

In summing up, lead times for precision mold components emerge as the natural outcome of disciplined processes that prioritize verification and stability over haste. By understanding the interconnected stages—from machining through inspection—toolmakers and OEMs can achieve predictable deliveries that support robust molding operations. In precision mold component manufacturing, lead time should be evaluated as the result of a controlled production system—not as a negotiable number—fostering reliability that pays off in the long run.