Precision mold components are specialized parts used within injection molds where dimensional accuracy, positional consistency, and surface integrity directly affect molding performance and product quality. They are essential because even small deviations in critical areas can lead to flash, short shots, accelerated wear, or unstable production cycles.

However, a common misconception persists across purchasing and sourcing decisions: many buyers assume all mold components are “precision” by default. In reality, precision requirements vary significantly depending on the component’s function, location, and performance impact.

Precision mold components are defined by function, tolerance, and performance impact—not by part name alone.

Understanding this distinction is fundamental for mold designers, OEM engineers, and sourcing teams who aim to balance performance, cost, and long-term tooling reliability.

In modern injection molding systems—especially those supported by integrated Custom Parts Manufacturing capabilities—precision decisions must be made at a system level, not based on labels or assumptions.

What Precision Mold Components Are — and What They Are Not

Precision mold components are components whose dimensional accuracy and surface condition directly influence mold functionality, repeatability, or part quality. They are not simply “important-looking” parts or components produced with tight tolerances by default.

From a technical standpoint, a mold component qualifies as “precision-critical” when:

- Its tolerance stack-up affects cavity geometry or shut-off integrity

- Its alignment influences part dimensions or cosmetic surfaces

- Its wear behavior impacts cycle stability or mold lifespan

By contrast, many general mold parts—such as backing plates, clamp plates, or non-functional spacers—may require strength and stability but do not demand micron-level accuracy.

This distinction matters because precision is a manufacturing requirement, not a marketing description. Treating every component as ultra-precision unnecessarily increases machining cost, lead time, and inspection complexity without improving mold performance.

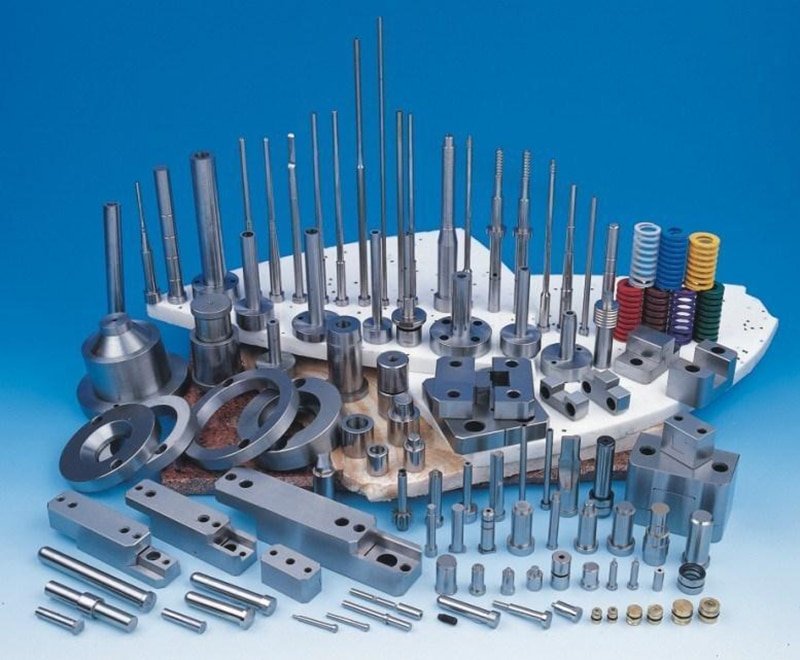

Core Types of Precision Mold Components

Not all mold components contribute equally to mold accuracy, and each type requires a different precision strategy. Understanding their functional role is more important than memorizing component names.

Mold Inserts

Mold inserts form critical sections of the cavity or core and are often responsible for detailed features, texture alignment, or localized wear resistance. Precision matters most in:

- Cavity geometry interfaces

- Shut-off areas

- Replaceable wear zones

Even small deviations can affect part dimensions or cosmetic appearance.

Core Pins

Core pins define holes, slots, or internal geometries. Their precision affects:

- Hole diameter consistency

- Concentricity

- Ejection stability

However, tolerance requirements vary depending on whether the pin is cosmetic-critical or purely functional.

Ejector Pins

Ejector pins must balance precision with robustness. Excessive clearance can cause flash marks or deformation, while over-tight fits increase seizure risk. Precision here focuses on:

- Fit consistency

- Surface finish

- Wear predictability

Sleeves, Guide Components, and Wear Parts

Guide pillars, bushings, sleeves, and wear plates control alignment and movement. Precision influences:

- Mold alignment repeatability

- Friction behavior

- Long-term stability under thermal cycling

Their tolerances are often functional rather than dimensional.

Key Functions and Performance Impact

Precision mold components directly influence how a mold behaves over thousands—or millions—of cycles.

From a performance standpoint, precision affects:

- Dimensional accuracy: Misaligned inserts or worn guide components lead to dimensional drift.

- Repeatability: Stable tolerances ensure consistent part quality across long production runs.

- Mold lifespan: Poorly controlled fits accelerate wear, galling, and fatigue.

- Injection stability: Variations in shut-off or alignment can cause flash, short shots, or pressure imbalance.

In practice, many molding issues traced to “process problems” are actually rooted in component-level precision mismatches rather than machine settings.

Typical Applications Across Industries

Industries demand precision not for branding reasons, but because their products leave no margin for inconsistency.

Automotive

Tight dimensional control ensures part interchangeability, structural integrity, and compliance with safety standards across high-volume production.

Electronics

Precision mold components enable thin walls, complex geometries, and consistent cosmetic finishes critical for housings and connectors.

Medical

Regulatory compliance, functional reliability, and cleanliness demand predictable tolerances and surface conditions—especially in disposable or implant-related components.

Industrial Automation

Components must withstand repeated mechanical stress while maintaining alignment and accuracy under continuous operation.

Plastic Consumer Products

Precision determines not only fit and finish, but also assembly efficiency and perceived quality at scale.

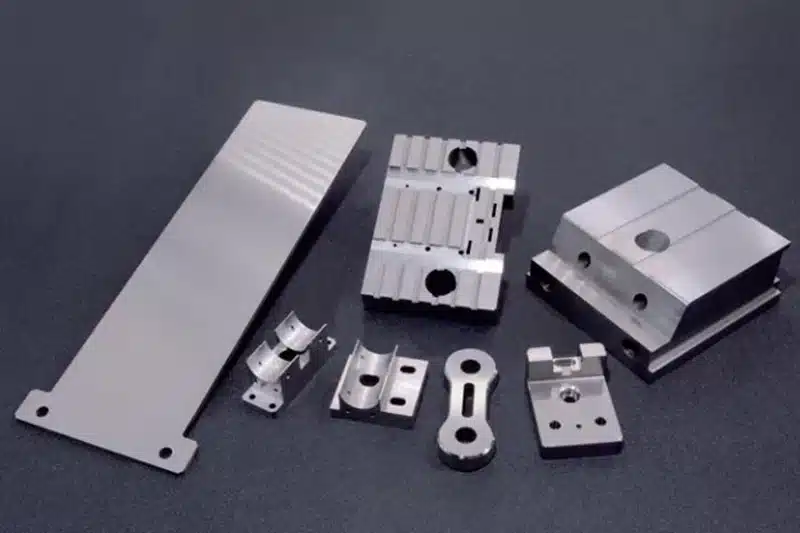

Materials and Manufacturing Considerations

Material selection defines whether precision can be maintained—not just achieved.

Different materials respond differently to machining, heat treatment, and operational stress. Choosing the right material influences:

- Dimensional stability over time

- Wear resistance under repeated cycles

- Thermal expansion behavior

A deeper understanding of mold component materials is essential because material choice directly affects whether a component can hold its intended tolerance throughout its service life—not just during initial inspection.

Precision, Tolerances, and Machining Reality

Precision is limited by machining reality, not specification intent.

Modern CNC machining allows extremely tight tolerances, but:

- Not all geometries are equally machinable

- Thermal distortion affects real-world results

- Measurement uncertainty increases at micron levels

Understanding achievable limits in tight tolerance precision machining helps engineers avoid over-specifying tolerances that increase cost without delivering functional benefit.

The goal is not maximum precision—but appropriate precision.

Common Misunderstandings About Precision Mold Components

Many sourcing mistakes stem from oversimplified assumptions about precision.

Common misconceptions include:

- All mold components need ultra-tight tolerances

- Higher precision always improves mold performance

- Precision requirements are independent of application context

In reality, unnecessary precision can introduce risk, not reduce it.

How OEMs Should Evaluate Precision Mold Components Rationally

Effective evaluation starts with function—not tolerance values.

OEMs and engineers should assess:

- Which components directly affect part geometry or mold movement

- Where tolerance stack-ups truly matter

- How precision influences long-term performance, not just initial fit

Balancing precision with manufacturability leads to more stable tooling, predictable costs, and fewer production disruptions.

Conclusion — Precision Is a Requirement, Not a Label

Precision mold components are not defined by their names or categories, but by their role within the molding system. Precision must be specified based on function, tolerance, and performance impact, not assumed by default.Ultimately, manufacturing capability and engineering judgment matter more than terminology. When evaluated systemically, precision becomes a tool for performance—not an unnecessary cost driver.