Learn how thermoplastics can be utilized and how they can be used sustainably.

Introduction: What Are Thermoplastics?

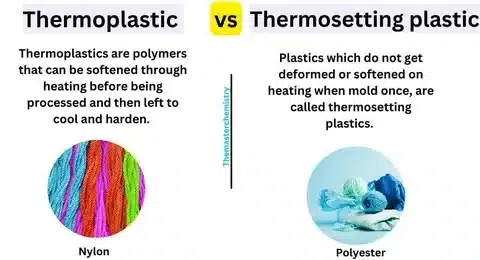

One of the most diverse and most popular types of polymers in the modern manufacturing industry is thermoplastics. Thermoplastics are essentially polymers that melt or soften when exposed to high temperatures and are hardened by being left to cool. This basic property makes them different and extremely useful in various industries as compared to other plastic materials.

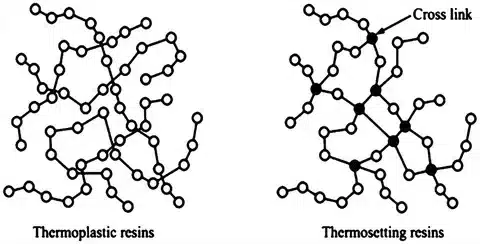

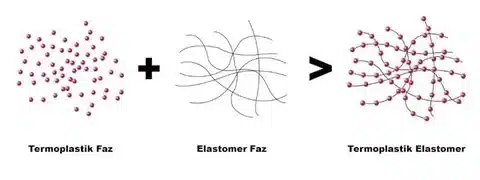

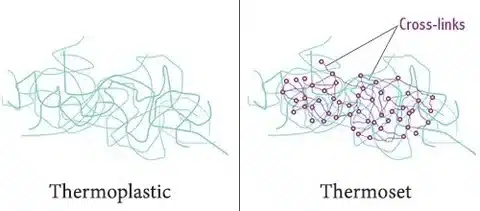

The main characteristic of thermoplastics is the possibility of performing reversible heating and cooling. Thermoplastics (opposed to thermoset plastics) can be heated, moulded, and cooled repeatedly, whereas the latter permanently harden once heated, and do not maintain their structural integrity. This is reversible, ensuring reshaping and recycling, making it an environmentally conscious option for both manufacturers and consumers.

Examples of thermoplastics that you will come across in everyday life include Polypropylene (PP) in food containers, Polyethylene (PE) in shopping bags, Polyvinyl Chloride (PVC) in pipes and flooring, Polystyrene (PS) in disposable cups, and Polyethylene Terephthalate (PET) in beverage bottles, and Polycarbonate (PC) in eyewear and electronic parts.

Core Properties of Thermoplastics

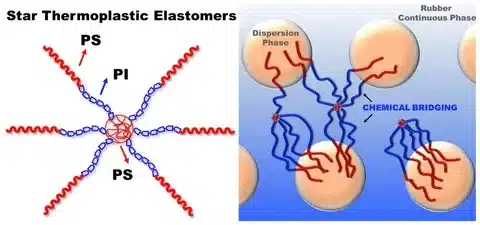

Thermoplastic materials have unique properties because of their molecular structure, which is a chemically independent macromolecule. These long-chain molecules are held jointly by comparatively weak intermolecular forces, which enable them to glide through one another as they are heated. It is this type of molecular arrangement that makes thermoplastics act in their typical manner.

Their greatest strength, both economically and environmentally, is probably the recyclability of thermoplastics. Heating and cooling can be repeated many times, thus reprocessing and recycling without significant loss in the properties of the material. It implies that thermoplastic waste can be gathered, melted, and recycled into other products, which will aid the principles of the circular economy.

The physical properties of thermoplastics have a pattern of predictability: they soften or melt when subjected to heat and can be shaped, formed, welded, and moulded. When they are cooled, they solidify and keep their new shape until heated again. This trait renders them the best choice in the manufacturing processes where precision and consistency are needed.

Everyday Applications of Thermoplastics

Thermoplastics have established themselves in our lives because of their versatility and processing ease. In packaging, they consist of food containers to retain the goods fresh, bottles to retain drinks, and wraps to retain goods during transportation. They are capable of application in food safety due to their resistance to chemical degradation or their resistance to act as a barrier.

Another significant sphere of use of thermoplastics is consumer goods. The same materials offer an ideal combination of functionality and affordability in the case of children’s toys that need safety and durability, or the use of storage containers and cooking utensils at home. Thermoplastics are also important to electronics housings due to their electrical insulation quality and their capacity to be shaped into sophisticated forms.

Thermoplastics have found their way into the automotive industry in various aspects of interior as well as exterior. The materials can reduce weight as compared to conventional metals without compromising on strength and longevity. A range of thermoplastic formulations is now being used to make dashboard components, door panels, and even parts of the exterior body.

Healthcare applications are a very important and expanding thermoplastics market. Their biocompatibility and sterilization properties of medical devices are useful in medicine, but pharmaceutical packaging depends on their barriers to prevent environmental influence on drugs. Innovative designs of medical devices are also possible through the capability to shape complex shapes.

The Manufacturing Process

The process of making thermoplastic products utilizes several proven processes, each with application- and quantity-specific applications. The most common process is probably injection molding, in which high-pressure plastic is forced into a mold cavity. The method is best used in creating complicated shapes with high accuracy and surface finish.

An additional basic operation is extrusion, in which thermoplastic material is pressed through a die to form continuous profiles such as pipes, sheets, or films. Blow molding is an extrusion process that incorporates air pressure to make hollow products such as containers and bottles. Thermoforming is a technique whereby thermoplastic sheets are heated and shaped over vacuum or pressure molds.

The benefits of these production methods are affordability in large-volume manufacture, scalability between prototype and mass manufacture, and the ability to produce complex shapes previously inaccessible to other materials. Most thermoplastic processing is automated and thus ensures consistency in quality and minimizes labour costs.

Nevertheless, other factors like the choice of material and set processing parameters play a critical role in the quality of products. To attain desired properties and dimensional precision, temperature control, cooling rates, and pressure settings should be fully optimized concerning each type of thermoplastic and each application.

Sustainability and Recycling

Thermoplastics’ sustainability signature is mostly determined by the recyclability of the materials, but this is accompanied by opportunities and challenges. The process of mechanical recycling is the collection, sorting, cleaning, and recycling of thermoplastic wastes into other products. This is suitable for clean and well-sorted materials, but will lead to degradation of properties with each recycling process.

A more sophisticated method is chemical recycling, in which thermoplastics are dismantled to molecular building blocks and subsequently reformed into new polymers. This is potentially a more expensive process that can restore the original properties of the material, but it needs more energy and more complex technology.

Some of the key problems of thermoplastic recycling are food residues, adhesives, and other materials contamination, and the difficulty of differentiating various plastics. Mixed plastic waste is not easy to recycle, and contamination may greatly lower the quality of recycled products.

Recent developments in the area have aimed at coming up with biodegradable variants of the same, but retain the positive characteristics of the thermoplastics, and could be broken down by the environment in a safe manner. Recycling technologies, such as enhanced sorting systems and chemical recycling processes, are also developing rapidly in order to cope with the existing constraints.

Future Trends in Thermoplastics

A number of promising new technologies are defining the future of thermoplastics. Smart materials are one avenue in which thermoplastics are combined with sensors and responsive components to formulate materials that can alter properties on being exposed to environmental changes. Such inventions pave the way for use in aerospace, automotive, and health fields.

Bioplastics made using renewable plant-based materials are on the rise in popularity as manufacturers and users are demanding greener alternatives. These materials are meant to offer comparable traits of the petroleum-based thermoplastics in terms of performance, but should offer a better end-of-life usage in terms of biodegradability or compostability.

The concept of the circular economy is spurring the production of a need to decrease waste and improve the recyclability of the entire thermoplastic lifecycle. Among these are product designs that are easier to recycle, new recycling technology, and market incentives to use recycled material in the new product.

Conclusion: The Enduring Importance of Thermoplastics

The use of thermoplastics is an inevitable product in modern society due to the incredible adaptability and multi-purpose nature of these materials in every industry. It is the packaging that ensures our food is safe, or it is the medical device that prevents a life without them; we could not be as creative or make life any better.

Thermoplastics are dynamic, and a continuous enhancement in material science has seen the development of new formulations that have enhanced properties. It might be an improved strength-to-weight ratio, higher temperature capacity, or higher recyclability, but scientists and manufacturers have yet to see the limit to what can be done with such material.

Most importantly, there is a commitment to greener practices that are changing the thermoplastics market. As the recycling of materials and bio-based alternatives becomes more and more viable, thermoplastics would be at the center stage to enable them to develop a more sustainable future without losing the performance properties that make them add value.