Introduction

Ever questioned yourself how aluminum can be so light and at the same time nearly indestructible? The magic is in the fact that the surface treatment process is very sophisticated, making the common aluminum a material that is strong, beautiful, and long-lasting.

A vane of aluminum is one of the most viable methods of improving the natural characteristics of aluminum so that it can be used in highly demanding applications in various industries. This post explores the anodizing process, the advantages of the process, and some more practical applications that demonstrate the importance of this treated aluminum in modern manufacturing.

What Is Anodized Aluminum?

Anodized aluminum is an aluminum that has been subjected to an electrochemical treatment called anodizing, a process that artificially increases the natural oxide film that develops on the surface of aluminum. Rather than coating the metal with paint or plating, anodizing changes the surface of aluminum into a hardening and inseparable constituent of the material. This is done to form a protective coating that is literally a part of the aluminum and therefore cannot be chipped, peeled, or flaked as with old-fashioned coatings.

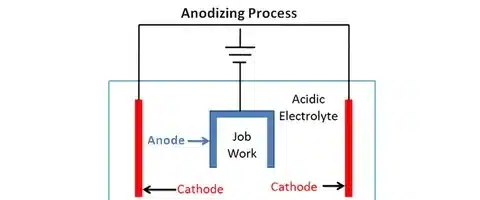

The anodizing procedure assumes that the parts of aluminum are immersed in an electrolytic solution, which is usually sulfuric acid, and that an electric current is passed through the system. This measured oxidation forms microscopic pores in the aluminum oxide coating and, accordingly, can be sealed to entrap superior properties and, where necessary, colors or dyes.

The Anodizing Process Explained

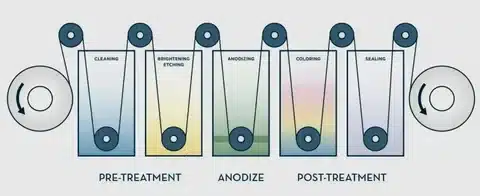

A series of steps to be followed by the anodizing is precise to get the best results:

Cleaning and Pre-treatment: The aluminum components are subjected to extensive cleaning to eliminate oils and dirt as well as surface contaminants. This could involve de-greasing, etching, and rinsing as a way of making the surface ready for uniform anodizing.

Anodizing Bath: Sulphuric acid is an electrolytic bath containing clean aluminum parts. Electric current is used, and the aluminum is the anode, and controlled oxidation of the surface is done.

Coloring (Optional): When it is required to be coloured with anodized aluminium, dyes or pigments are added to the porous oxide layer when it is still open and welcoming to being coloured.

Sealing: The last step is adding stability to the porous oxide layer by usually using hot water or steam to seal the porous structure and secure the protective qualities and color applied.

The careful timing, temperature, and chemical concentration are critical in every step to ensure a high-quality output is constantly produced, and the quality should be at the standard of the industrial level.

Benefits of Anodized Aluminum

Enhanced Durability

Anodized aluminum has benefits that start with its outstanding durability. The anodizing process enhances the resistance of the aluminum to any corrosion by up to a 10 times factor of raw aluminum. This increase in corrosion resistance makes anodized aluminum complete in outdoor service and in tough environmental situations where moisture, salt, and chemical exposure would easily corrode untreated metals.

Aesthetic Appeal

Aesthetic versatility is enhanced by the anodized aluminum, which can receive a wide variety of colors and finishes. Through the anodizing process, it is possible to reproduce colors consistently, and any shade, subtle metallic, or bright color can be reproduced. It also looks the same in the long run without fading and discoloration as experienced by painted surfaces.

Environmental Benefits

The anodizing is environmentally friendly with recyclable aluminum and no product of hazardous waste. Anodized aluminum retains the recyclability of aluminum itself and increases product life periods, eliminates frequent replacement of the product, and lowers the environmental footprint.

Common Applications

Architecture: Uses of anodized aluminum in buildings are seen in facades of buildings, window framing, door framing, and curtain wall systems. Its weathering resistance and flexibility in design have made the material a favorite in modern and traditional architectural designs.

Consumer Electronics: Smartphones, laptops, tablets, and other electronic gadgets often have anodized aluminum housings. The material offers electromagnetic protection and offers the high-end look and feel that the consumer anticipates in high-end electronics.

Automotive: Manufacturers of cars also use anodized aluminum in parts that are subjected to the most extreme environments, such as trim parts, heat exchangers, and ornamental parts. The lightweight nature and the corrosion resistance of the material make it efficient for the vehicle and long-lasting.

Sports Equipment: Outdoor sports equipment, bicycle frames, and camping gear enjoy the strength-to-weight ratio and the weather resistance of anodized aluminum. The material can withstand repeated stress cycles as well, and it does not change its appearance even when subjected to the elements.

Anodized Aluminum vs. Raw Aluminum

| Property | Anodized Aluminum | Raw Aluminum |

| Appearance | Uniform, customizable colors and finishes | Natural metallic silver, prone to oxidation spots |

| Durability | High corrosion resistance, scratch-resistant surface | Susceptible to corrosion and surface damage |

| Maintenance | Low maintenance, easy to clean | Requires frequent cleaning and protective treatments |

| Wear Resistance | Excellent wear resistance due to a hard oxide layer | Softer surface, more prone to scratching and wearing |

| Color Options | Wide range of colors and finishes available | Limited to a natural aluminum appearance |

| UV Resistance | Excellent UV stability, won’t fade | May discolor over time with sun exposure |

Maintenance and Care Tips

Proper maintenance enhances the durability and appearance of the anodized aluminum many times. A soft cloth or sponge may be applied to the surface in order to clean the surface of the anodized aspect using mild detergents to avoid any scratches to the surface. Rough chemicals, steel wool, or abrasive cleaners should not be used since they will remove the protective oxide coating.

In the outdoor cases, frequent cleaning with clean water would be helpful in the removal of salt, dirt, and pollutants that would progressively affect the surface. Always wash thoroughly during cleaning to wash all cleaning residues and dry using a soft cloth in order to prevent water spots.

Strong alkaline or acidic cleansers must not be utilized and will kill the anodized layer. When it comes to deeper cleaning, use the manufacturer’s suggestion of the appropriate cleaning product that is particularly targeted at the application on anodized aluminium surfaces.

Conclusion

Anodized aluminum is a perfect combination of structure and purpose because it is more durable, aesthetically flexible, and environmentally responsible in a single material solution. In the process of controlled anodizing, common aluminum is converted into a high-quality material, which is resistant to corrosion and can take on vibrant colors and retain its looks over the decades of usage.

Since the marvels of architectural wonders up to the exact and accurate electronic devices, the use of anodized aluminum is continuously growing as the industries appreciate the rare characteristics of anodized aluminum and how it combines strength, beauty, and sustainability. In an architectural project, a consumer product, or in need of very long-lasting and performance-oriented components in a challenging application, anodized aluminum has the performance characteristics and design flexibility to make your vision come true, in addition to great long-term value and performance.