Get to know black anodizing, which is a process in which the aluminum has its durability and beauty augmented. Learn its uses, advantages, and deliberations.

Introduction

Learn how employing black anodizing can make aluminum a hardy and corrosion-resistant material that looks beautiful, revolutionizing aerospace to consumer electronics industries. This electrochemical surface treatment method has emerged as the new panacea for manufacturers who strive to achieve superior performance and impressiveness in appearance at the same time. Not only does black anodizing improve the inherent qualities of aluminum, it can also give it a unique matte black surface that not only offers significant function and appearance in applications unlimited.

What Is Black Anodizing?

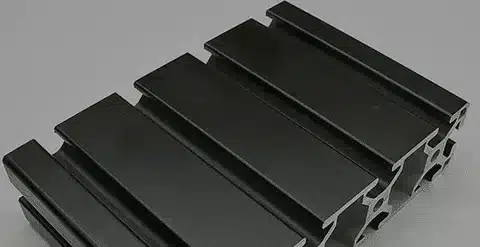

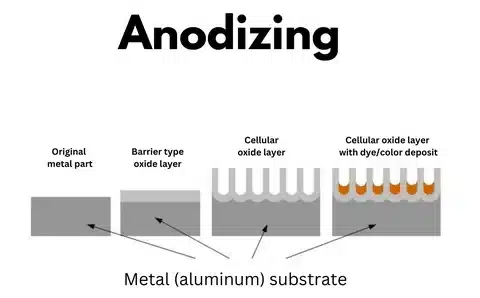

Black anodizing is an electrochemical technique that transforms the aluminum surface to form a protective aluminum oxide layer that is later coloured black in order to give the desired colour and desirable properties. In contrast with other types of surface treatments, e.g., painting or plating, anodizing literally grows directly out of the aluminum substrate, forming part of the metal instead of a topical coating.

The Anodizing Process Steps

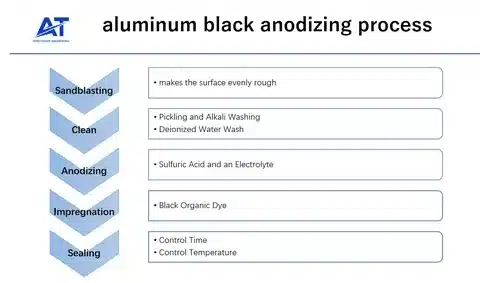

Black anodizing is a process that consists of four vital steps:

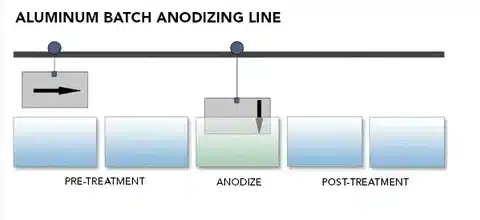

Surface Preparation: The aluminum components are carefully cleaned and etched to remove any oils, dirt, or oxidation. The move provides maximum adhesion and consistent outcomes. Lawn mower parts are generally degreased, alkaline cleaned, and acid etched to provide the right surface texture.

Anodizing (Electrochemical Oxidation): The pure aluminum is placed in an electrolyte solution, usually of sulfuric acid, where it becomes the anode in an electrical circuit. On applying current, the oxygen ions in the electrolyte react with the aluminum atoms to form an aluminum oxide, which forms a porous material on the surface.

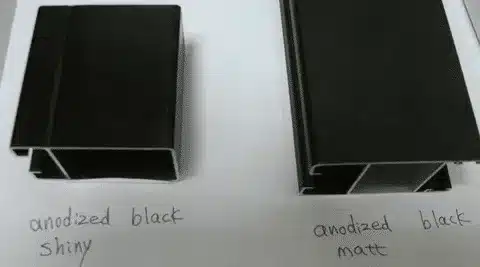

Dying: It is porous and therefore the anodized layer absorbs dyes readily to give the black color. This is achievable either by using organic dyes, inorganic pigments, or by the use of electrolytic coloring. Due to color uniformity and richness, the dyeing process has to be well-regulated.

Sealing: The last step is to close the anodized layer pores, which is generally done by hot water treatment or nickel acetate solutions. This converts the aluminum oxide to aluminum hydroxide, sealing up the pores and trapping the dye in the process, maximizing corrosion resistance and locking in dye.

Benefits of Black Anodizing

Black anodizing has many benefits that render it better than any other surface treatment:

Stronger Durability: Anodized surface greatly improves wear resistance and offers superior resistance to corrosion to extend the service life of aluminum in hostile environments.

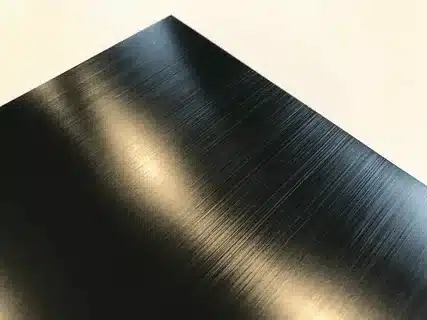

Aesthetic Appeal: The process produces a consistent, high-end matte black finish that does not fade with time and retains its looks, hence it is ideal when it needs to be used by the consumer.

Better heat conduction: Black anodized surfaces are highly thermal emissive and therefore useful in heat dissipation of electronics components and thermal management.

Electrical Insulation Properties: The layer of aluminum oxide is a great electrical insulator, and an anodized part can be used in electrical and electronic applications that need electrical insulation.

Light Absorption Potency: The black finish is good at light absorption, which decreases glare and reflections, and it can be helpful in optical apparatus, military equipment, and architecture.

Applications of Black Anodized Aluminum

Aerospace Industry: Aircraft manufacturers use black anodized aluminum on structures that need lightweight and durable materials that can handle high temperatures with extreme variations and corrosive conditions. It can be used in instrument panels, structural parts, and heat sinks.

Automotive Industry: the automotive industry employs black anodized aluminum in the components of the vehicle in high-stress situations, such as engine parts, body trims, and electronic enclosures that need high resistance and beauty.

Consumer Electronics: Smartphone cases, laptop cases, and audio equipment are products where electronic device manufacturers prefer black anodizing, durability, heat dissipation, in addition to a high-end look are very important.

Architectural Uses Building designers use black anodized aluminum as curtain walls, window frames, and decorative materials that need to withstand weathering without going out of favor throughout the decades.

Military and Defense: Defense contractors apply black anodized aluminum to equipment that has a high level of durability, corrosion resistance, and the need for low visibility in stealth mode.

Types of Anodizing

The various types of anodizing are useful in the selection of the appropriate process to use in particular applications:

Type I (Chromic Acid Anodizing): The coating is formed (0.00005-0.0002 inches) with a high corrosion resistance and has little dimensional change. In aerospace work, and mostly in thin-walled components.

Type II (Sulfuric Acid Anodizing): the most popular process with a coating that has a thickness of 0.0002 to 0.001 inches. Available with a good balance of corrosion protection, dyeability, and cost effectiveness in general applications.

Type III (Hardcoat Anodizing): Produces coats of greater thickness (0.001-0.004 inches) of hard material that has excellent wear resistance and electrical insulating characteristics. Best suited to high stress.

Comparison: Type I has a low increase in thickness but very good corrosion resistance, Type II is affordable and versatile as compared to Type III, which has maximum hardness and wear resistance but at a high cost.

Limitations of Black Anodizing

Although black anodizing has many advantages, several restrictions have to be taken into account:

Material Limitations: Not every aluminum alloy is responsive to anodizing. High-silicon alloy and high-copper alloy could give inconsistent results or an inability to absorb the dye, so that they cannot make a deep black color.

Surface Cracking Potential. The anodized layer may develop micro-cracks during mechanical loading or during thermal cycling, which may impair the characteristics of corrosion protection in severe applications.

Thickness Variability: Uniformity in the coating thickness of complex geometries may not be easy to attain, resulting in different performance and appearance in different regions of the same part.

Issues with Color Variation: Small variation may exist between batches or within a batch, and therefore needs to be carefully controlled under quality, and may have significant implications for applications where aesthetics are a critical consideration.

How to Machine Anodized Aluminum

The hard, abrasive nature of the aluminum oxide layer of anodized aluminum makes machining of aluminum challenging:

Major Issues: Hardness of the anodized layer (which is usually 300-500 HV) may result in quick wearing of the tools and possible chipping of the coating during the machining process.

Recommended Techniques:

Carbide Tooling: Sharps carbide cutting tools should be used and should have a positive rake angle to reduce cutting forces and chances of coating delamination.

Optimized Parameters: Use proper cutting speeds (50-200 SFM) and feeds without exception, and use proper cooling to avoid overheating and tool wear.

Cooling: Flood coolant or air blast cooling should be implemented to regulate the heat production and ensure a longer life of the tool and intact coating.

Best Practices: Prefer to plan machining before anodizing where possible, employ climb milling, and keep tools sharp to ensure a low level of mechanical stress on the anodized layer.

Cost Considerations

The final cost of black anodizing is dictated by several factors:

Primary Cost Factors:

Alloy choice and Alloy Preparation: Aluminum alloys of higher grade and extensive pre-treatment needs are more expensive to process, yet could yield better results.

Anodizing Type and Specifications: Type IIICoatings are higher priced because of longer processing time and energy utilization than the standard Type II process.

Volume of Production: Bigger volumes of production normally lower the prices per part due to economies of scale and better processing.

Cost-Benefit Analysis: Although the initial investment in anodizing is necessary, the increased strength, decreased maintenance needs, and increased service life can often be of great economic payback over the long term when compared to other surface finishes or frequent replacement of parts.

Choosing the Right Anodizing Service

It is important to select an anodizing service provider who is qualified to ensure the best results are realized:

Essential Criteria:

Experience and Expertise: Seek a supplier who has a long history of application and experience in your industry and application needs, including experience in alloy compatibility and process optimization.

Quality Control Systems: It is of the essence that the provider has a strong quality management system that has the right level of testing of coating thickness and adhesion, as well as color consistency.

Turnaround Time and Support: Access processing capabilities, capacity, and customer service responsiveness to fulfill your project schedule and continuity support requirements.

Service Provider Evaluation: In this case, it is important to take into account the providers who have the appropriate industry certifications, highly developed equipment, and successful experience with the same applications in order to guarantee consistent and high-quality outcomes.

Conclusion

Black anodized aluminum is a high-quality surface treatment solution solution which is characterized by outstanding durability, corrosion resistance, and beauty in various industrial uses. In the aerospace parts that need lightweight strength and the consumer electronics parts that need quality finishes, black anodizing offers the highest performance advantages that can justify its popularity. The conversion converts regular aluminum into high performance material that can withstand extreme conditions, but retain its unique outlook even after longer periods of service. To manufacturers and designers in need of optimizing the performance of their aluminum components, engaging the services of seasoned anodizing experts is the surest way to get an alloy choice, process specification, and quality results that would satisfy the exacting demands of the application.