Introduction: What Is Blow Molding?

One of the most practical and multifaceted manufacturing technologies in the production of hollow plastic components is blow molding. This novel process converts unrefined thermoplastic compounds into a stunning range of products that we can see and consume in our everyday lives – be it water bottles and food containers or car fuel tanks and irrigation pumps in agriculture.

The blow molding technique is both efficient and precise, which is why it is a perfect selection when it comes to mass production in such industries as the packaging industry, automobile industry, medical industry, and agricultural industry. Through controlled air pressure and very well-planned molds, manufacturers can make complex hollow shapes with the same thickness of the walls and with a high level of dimensional accuracy.

The Three Main Types of Blow Molding

It is important to know the various methods of blow molding to choose the most appropriate method for your production requirements. Both approaches have particular advantages and uses.

Extrusion Blow Molding (EBM)

Extrusion blow molding is the most popular type of blow molding, especially in manufacturing large-volume containers and bottles. This process incorporates two halves of molds and a parison that is an extruded plastic tube heated vertically between the two halves. The parison is placed between the mold, and compressed air fills the plastic to fill the mold cavity. This method is ideal in the production of products such as milk jugs, detergent bottles, and automotive fuel tanks, which is very cost-effective when there is a large production run.

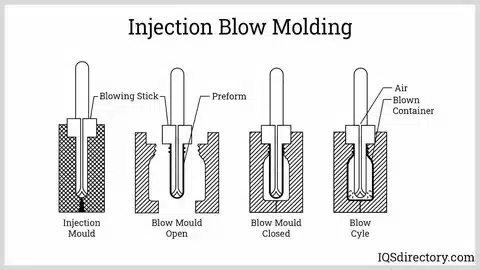

Injection Blow Molding (IBM)

Injection blow molding is a blend of injection and traditional blow molding, which makes it the best process to use in manufacturing small, accurate containers with a high-quality neck finish. It is initiated by injecting a raw molten material of plastic onto a core pin to create a preform that is moved to a blow molding station, where compressed air is used to mold the final product. This technique is especially suitable for pharmaceutical bottles, cosmetic containers, and food packaging of small dimensions, where dimensional precision and surface finish are of primary importance.

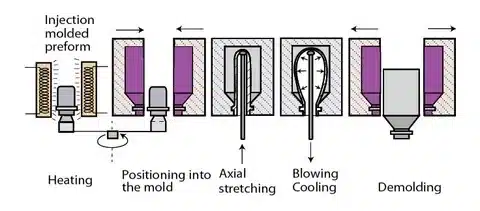

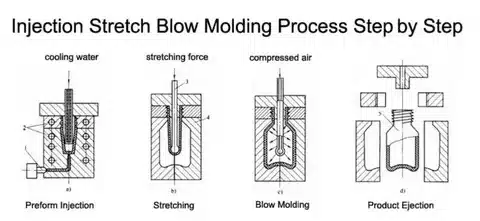

Injection Stretch Blow Molding (ISBM)

Injection stretch blow molding is by far the most advanced type of blow molding; it is the process of injection molding that is stretched and blown. Under this, the preform is created by injection molding and the resultant is stretched and blown into the final shape. Biaxial orientation gained by stretching gives the final product an ideal combination of mechanical strength and barrier properties to be used with carbonated drinks, wide-mouth jars, and specialty packages that need high strength and clarity.

Common Materials Used in Blow Molding

The choice of blow molding materials is important in the attainment of the best product performance and manufacturing efficiency. All thermoplastics have their own qualities that can be applied in certain applications.

Polyethylene (PE) has been the workhorse of the blow molding applications with excellent chemical resistance, flexibility, and economy. High-density polyethylene (HDPE) is preferred in rigid and barrier containers, whereas low-density polyethylene (LDPE) offers squeeze bottles and soft packaging flexibility.

Polypropylene (PP) offers better heat resistance and chemical compatibility, so it is ideal in applications in the automotive sector, labs, and in food containers that need the sterilization characteristics. It is also applicable to living hinges and flexible components due to its great fatigue resistance.

Polyethylene Terephthalate (PET) has highly clear, strong, and barrier properties, especially when subjected to injection stretch blow molding. This is a prevalent material in the beverage sector and is also used as a food packaging material that needs a long shelf life.

Polycarbonate (PC) is well-suited to safety applications, automotive lighting components, and medical devices that need sterilization ability due to its excellent impact resistance and its optical clarity.

Acrylonitrile Butadiene Styrene (ABS) is a compound that takes the form of a blend of Strength, chemical resistance, and a high-quality surface, which makes it ideal in automotive interiors, electronic housings, and consumer products that need to be painted or decorated. In materials choice, one should take into account the end-use, regulatory requirements, processing temperature, and cost-limiting factors. The choice of the material must match the desired process of blow molding and the final use.

The Blow Molding Process Explained

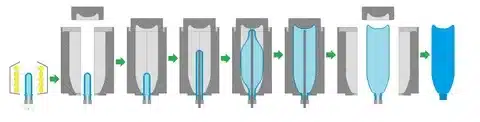

The blow molding process is a systematic process that converts raw materials made of plastic in the form of hollow products by controlling temperatures and pressure accurately.

It starts by melting and extruding thermoplastic resin. Raw plastic pellets are inserted into an extruder, and it is heated to the optimum processing temperature of 180 °C to 250degC depending on the material. The melted plastic is then molded into a hollow tube (parison) or formed by means of special tooling.

Then there is the critical blowing stage in which the plastic is blown to its final shape. The parison or preform is placed in the cavity of the mold, and compressed air is injected using a blow pin or a needle. The heat is then applied to the plastic under pressure of air (usually between 80 and 600 psi) and pressed against the mold walls in order to mold it to the required shape. Air pressure should be monitored to ensure the distribution of wall thickness and the elimination of defects.

The last phase is cooling and ejection of the modeled part. Mold cooling systems remove heat from the plastic, and the plastic hardens in place without losing shape. Depending on the part thickness and the material used, the cooling time can be between 10 and 60 seconds, on average. The part is then molded and cooled, and the mold is opened, and the finished part is forced out, usually necessitating removal of surplus material due to parting lines.

Mold design is the element that significantly affects the quality of final products. Venting, placement of cooling channels, and surface finishes are the factors that have a direct influence on part appearance and dimensional accuracy. High-tech models, such as programmable wall thickness and multi-layered designs, are introduced in the mold design to provide high performance.

Innovations in Blow Molding: 3D Printed Molds

The adoption of 3D printing technology is transforming the work of blow molding, especially in low-volume production models and prototyping. 3D printed molds are unprecedented in terms of design iteration and tremendous savings of money when it comes to specialized production.

Conventional manufacturing of molds takes weeks or months and can be costly, and often, companies cannot test design concepts or make small quantities of molds. 3D printed molds can be made in days, and it is easy to do initial prototyping and validation of designs. This is especially useful in the case of personal packaging, special containers, and products of niche markets.

Other companies have managed to use 3D printed molds in the 3D printing of stretch blow molding. An example is that a 3D printed preform mold is being used by the packaging companies to test new bottle designs without the need to commit to costly steel tooling. This solution saves 70 percent of development costs and up to 90 percent of prototyping costs.

Nevertheless, 3D printed molds possess such limitations as the reduced durability of the molds in comparison with the traditional steel molds and the limitation on the quality of the surface finish that can be attained. They are best suited to prototyping, small production volumes, and to those tasks in which quick design updates are expected.

Design Considerations for Blow-Molded Parts

To achieve success in blow molding, design principles should be considered carefully in order to provide manufacturability, quality, and functionality of the finished product.

Wall thickness uniformity. One of the most important design factors is uniformity of wall thickness. The natural characteristic of blow-molded parts is the varying thickness of the walls as a result of the stretching behavior of plastic during inflation. These variations have to be considered by the designers, and features such as preform design optimization or parison programming should be added to reach an acceptable thickness distribution. Normal thickness on walls is in the range of 0.5mm to 6mm, with reference to the size and application factors of the part.

Parting line placement. The position of parting lines has a big influence in terms of aesthetics and functionality. Parting lines must be made in such places that they require the least amount of visibility and do not affect the integrity of the structure. It is also possible to make strategic placements to ensure material flow and proper venting during the process of molding.

Incorporating functional features. The functional features like handles, threads, and mounting points must be considered with material flow and stress distribution in mind. Handles are to be made with sufficient draft angles and with sufficient fillet radii so as to avoid stress concentrations. Threaded features should take into consideration shrinkage and proper dimensional accuracy to meet the assembly requirements. Other design considerations are keeping the draft angles constant (usually 0.5 ° to 2deg), not using sharp corners which form stress concentrations, and adding ribbings or structural elements to increase rigidity without much increased use of materials.

Applications of Blow Molding

The breadth of blow molding applications extends to many industries, and each of them is taking advantage of the capability of the process to create complex hollow forms effectively and economically.

Packaging applications. The biggest area of blow molding use is packaging applications. Bottle packages of consumer goods, such as bottles of drinks, foodstuffs, personal care packages, and household chemical bottles, are manufactured using blow molding. The process allows complex shapes with built-in handles and pour spouts, and decoration features, and has outstanding barrier properties and appearance.

Automotive components. Automotive parts make use of blow molding to create fuel tanks, air ducts, resonators, and fluid reservoirs. The advantages of these applications are that the process has the capability of developing complex internal geometries, incorporating mounting capabilities, and the durability needed in an automotive environment. The high-technology multi-layer blow molding methods offer superior barrier properties to fuel system parts.

Agricultural and industrial applications. Blow molding is used in irrigation tanks and chemical storage containers, as well as specific equipment housings used in agriculture and industrial applications. The products are usually large, chemical-resistant, and require the ability to tolerate UV effects, so blow molding is a perfect manufacturing option.

Blow molding of containers that need sterile conditions, dosing ability, and regulation is increasingly being used by the medical and pharmaceutical industries. The process facilitates the incorporation of tamper-evident characteristics and child-resistant closures without sacrificing the quality.

Challenges and Limitations

Although it is versatile, there are various challenges associated with blow molding that manufacturers need to take into consideration when considering this process in their applications.

High initial tooling costs. Initial tooling cost is a huge entry barrier, especially with complex molds, which need a specific temperature and advanced automation. Blow molding is most cost-effective for large-volume production runs because steel container molds cost tens of thousands to hundreds of thousands of dollars. This cost model may be prohibitive to a small business or niche applications.

Design constraints. Blow molding has design limitations that restrict the complexity that can be attained as compared to other manufacturing processes. The process has issues with forming internal features, intricate undercuts, or components that need to be tightly dimensionally controlled. The applications where it is important to have uniform material distribution may also be a problem due to the variation of the wall thickness inherent to the process.

Material limitations. Limitations in materials constrain the blow molding process to include thermoplastic materials, which are capable of heating and reforming. High-performance polymers are not always suitable because of the processing temperature and thermal degradation. Also, the production usually demands materials that have certain melt flow properties to work best.

Issues of quality control involve how to control flash removal, maintenance of uniform wall thickness, and how to avoid defects like thin spots or surface blemishes. The problems are such that they need an advanced monitoring system and highly trained operators to maintain the quality of production.

Future Trends in Blow Molding

The blow molding industry is still developing with technology that increases efficiency, sustainability, and product capabilities.

Automation and artificial intelligence integration. The integration of automation and artificial intelligence is changing the operations of the blow moulding. Intelligent manufacturing is provided with real-time measurements, predictive maintenance, and automated quality control. AI-based mechanisms have the potential to continuously optimize the parameters of the processes and minimize the amount of wasted materials, and enhance uniformity. Machine learning algorithms are used to analyze data about production and give optimal settings for new products and new materials.

Sustainable materials development can resolve environmental issues and concerns that are increasing by developing bio-based plastics and using recycled materials, and enhancing recyclability. High-end barrier technologies allow to use of thinner wall sections and protect the product, consuming less material. With the use of chemical recycling technologies, food-grade containers can be produced out of post-consumer waste.

On-demand and localized manufacturing trends prefer flexible production systems with the ability to changeover swiftly and produce small batches. This trend is fueling evolving modular molding systems and fast tooling technologies that minimize set-up time and facilitate cost-effective short production. Technologies like IoT sensors, digital twins, and blockchain traceability that make up Industry 4.0 are making manufacturing more transparent and connected. These technologies make it possible to optimize real-time, predictive maintenance and full supply chain visibility.

Conclusion

Blow molding has made its name an indispensable manufacturing procedure, and it keeps on defining the manufacturing industries of packaging and the automobile industries, as well as the medical and agricultural industries. Its remarkable capability to make complex hollow shapes with great material productivity, coupled with constant technological advancements, such as 3D printed molding, automation implementation, and sustainable material innovations, ensures that it has always been relevant in the contemporary manufacturing process. With the tendency of companies to find cost-effective methods that can allow them to manufacture high-quality hollow plastic parts, blow molding presents a reliable method, versatility, and scalability that make it a preferred solution among both experienced manufacturers and businesses that need to introduce innovative products to the market.