In choosing the appropriate bolt, screw, or threaded part to work on your project, the knowledge of thread specifications is the difference between a sturdy connection and a very expensive failure. Regardless of whether you are doing automotive repair, production of accurate parts, or just a simple home repair, understanding how to determine and calculate threads per inch (TPI) versus thread pitch is crucial to preventing thread stripping, ensuring appropriate torque, and safety protocols.

The misunderstanding of inch-based TPI measurements and metric thread pitch can often cause the mismatch of fasteners and project delay. This guide will introduce you to these basic concepts, give you practical methods of measuring, and enable you to choose with confidence the appropriate threaded parts for any application.

What is TPI?

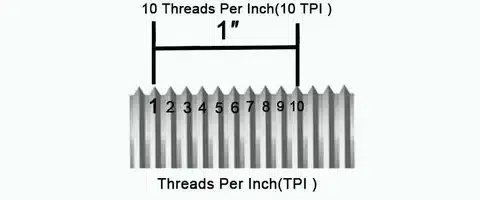

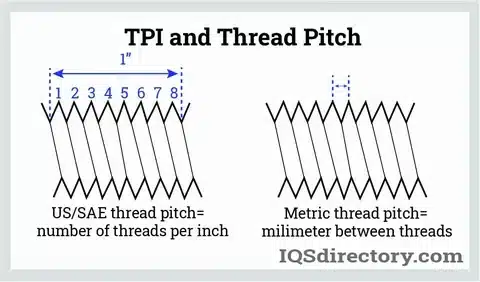

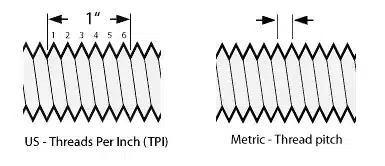

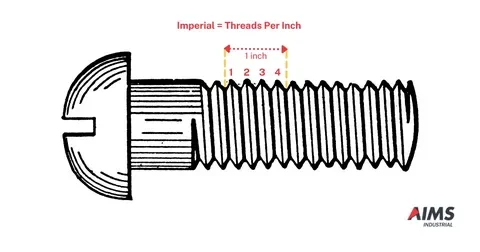

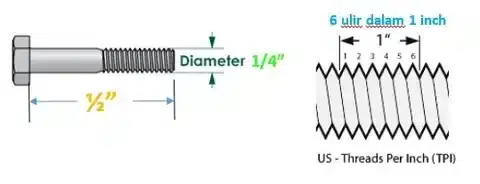

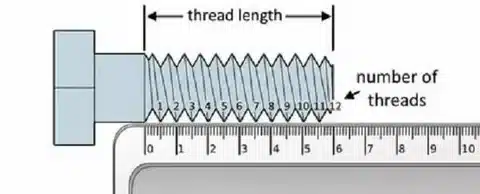

Threads Per Inch (TPI) is the actual number of threads that a threaded fastener has in a single inch in length. This is a measurement system mainly practiced in the United States and based on the Imperial measurement standard.

As an example, when you look at a bolt that is printed with 4 -20in, this means:

- ¼ inch nominal diameter

- 20 threads per inch (TPI)

The major features of TPI measurement:

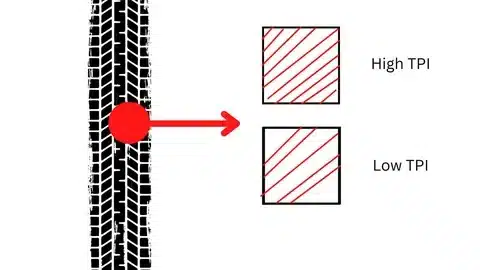

- The larger the TPI number = the smaller the threads (more threads per inch)

- Reduced TPI value = larger threads (fewer, larger threads per inch)

- Determined by thread gauges, caliper, or by counting threads in a given length.

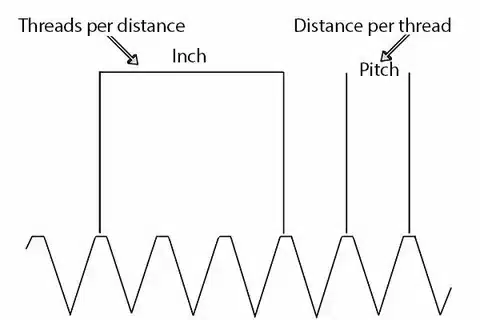

To accurately estimate TPI, subtract one inch and then take the number of complete thread peaks in that distance, or take the number of threads over a longer distance and divide by the measured distance in inches.

What is Thread Pitch?

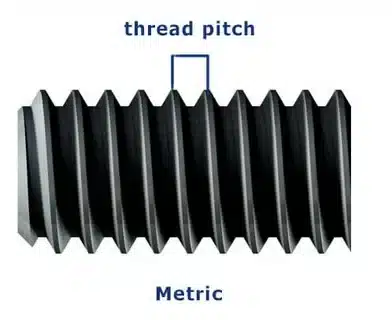

Thread pitch: A metric equivalent of TPI is the spacing between matching points on sequential threads. This is measured in millimeters, and it is the distance between each thread.

It is about the correlation between thread traits and pitch:

- Fewer pitch numbers = thinner threads (those that are nearer to each other)

- The higher the number of the pitch, the coarser the threads (the more distant the threads).

- Normal metric notation: M10 x 1.5 (10mm diameter, 1.5mm pitch)

Practical measurement hint: It can be more convenient to measure the distance between 10 threads and then divide by 10 to work out the thread pitch, and not attempt to measure the small distance between separate threads. Such an approach minimizes error in measurement and helps to obtain better results.

Metric vs. Inch-Based Threads—The Difference

The basic distinction between the two systems is the process of measurement and the region of use. In the United States, TPI (threads per inch) prevails, but thread pitch (measured in millimeters) is the international standard used in most other countries (including Europe and Asia).

System conversion: To change the metric pitch to TPI: TPI = 25.4/pitch (mm). To change TPI to the metric pitch: Pitch (mm) = 25.4/TPI

Analogy with the real world: Consider thread pitch as wavelength in physics- it is the spacing between repeating patterns. TPI is similar to frequency- it counts the number of patterns within some distance. Radio waves can be characterized either by wavelength or by frequency, and threads can also be characterized by either pitch or TPI.

This is an essential difference when one has to source the replacement parts abroad or deal with the devices that are produced in other nations. The improper system may give cross-threaded, stripped fasteners or total incompatibility.

Coarse vs. Fine Threads

The speed of fastener performance and application capability is heavily influenced by thread density. Knowing when to apply coarse and fine threads may enhance joint strength, ease of assembly, and long-term reliability.

Coarse Threads (Lower TPI / Larger Pitch):

- There is quicker assembly and disassembly.

- Improved work with soft materials (wood, plastic, aluminum).

- Less susceptible to rubbish or rust.

- Better for shearing use.

- Criterion of most general-purpose applications.

Fine Threads (Higher TPI / Smaller Pitch):

- More holding power because of more thread contact area.

- Thin-walled materials are better.

- Favorite when making precision adjustments and calibration.

- More vibration-resistant loosening.

- Usually used in automotive, aerospace, and precision manufacturing.

Course or Fine threads: This is based on your application needs, the material characteristics, and the conditions surrounding the application. Fine threads are superior in stressful, precision applications, and coarse threads are versatile and easy to use.

How to Measure & Identify Threads

The proper tools and methods are needed to identify a thread accurately. The following is a step-by-step method for measuring threads:

Using Thread Gauges (Most Accurate):

- Choose a gauge set (metric or Imperial).

- Try out various gauge pins on your threaded fasteners.

- The appropriate gauge will be tight and not loose.

- Read the gauge, TPI, or pitch.

Using Calipers or Rulers:

- In the case of TPI, how many thread peaks are in one inch?

- To determine pitch: Determine the distance between parallel points on successive threads.

- Alternative procedure: Count on 10 threads and divide the measured distance by 10

Using Standard Reference Charts:

- Measure the nominal diameter first.

- Check your thread count with UNC (Unified National Coarse) or UNF (Unified National Fine) standard charts.

- To determine the common designation, match the diameter and the number of threads.

Pro tip: Threads may be worn or damaged, so a longer distance (say 10 threads) should be measured and divided to get more accurate results than attempts to measure the spacing between specific threads.

Common Fastener Examples & Reference Table

| Size | UNC (Coarse) | UNF (Fine) | Metric Equivalent |

| #10 | 10-24 | 10-32 | M5 x 0.8 |

| 1/4″ | 1/4-20 | 1/4-28 | M6 x 1.0 |

| 5/16″ | 5/16-18 | 5/16-24 | M8 x 1.25 |

| 3/8″ | 3/8-16 | 3/8-24 | M10 x 1.5 |

| 1/2″ | 1/2-13 | 1/2-20 | M12 x 1.75 |

| 5/8″ | 5/8-11 | 5/8-18 | M16 x 2.0 |

This is a table of reference to indicate the connection between Imperial and metric threading standards. Observe that coarse threads (UNC) have lower TPI, and fine threads (UNF) have more threads in the same length. The metric equivalents are approximate size comparisons, not exact substitutes, because they have other thread profiles and specifications.

Real-World Applications & Tips

The knowledge of thread specifications is essential in processes where safety, accuracy, and dependability are the most essential. In car production, an inaccurate choice of the threads may result in disastrous failures. Assembling medical devices needs a precise thread match in order to have sterile and secure connections. Objects of industrial machinery rely on the correct threading in order to operate safely in extreme conditions.

Common consequences of thread misidentification:

- Damaged threads that need to be repaired at high cost.

- Poor use of torque causes joint failure.

- Dangers of loose or failed connections.

- Problems with mixing Imperial and metric systems.

- Delays in production and higher costs of production.

Best practices for thread selection:

- Before replacing fasteners, you must always check the manufacturer’s specifications.

- Stock thread gauges or pitch gauges are to be identified in the field.

- Removal of a sample fastener is a professional way of identifying the sample when in doubt.

- Take into account the environmental factors (corrosion, vibration, temperature) when selecting the coarse and the fine threads.

- Keep metric and Imperial fasteners separate, or they will become mixed.

When to seek professional guidance: If you are dealing with the critical

applications, e.g., structural connections, pressure vessels, or safety equipment, then consult engineering professionals or look up what is required by the codes and standards before making thread choices.

Conclusion

Knowing the difference between threads per inch (TPI) and thread pitch will leave you a better decision maker when it comes to picking fasteners, avoid costly mistakes, and ensure reliable attachment in your projects. It should be remembered that TPI is applied to show the density of the threads in the Imperial system, and the distance between threads in the metric system is shown by pitch. The similarity between the two is that they share the same fundamental purpose; however, they require dissimilar measurement and conversion equations when used to the systems.

Your next threading issue will become clear on how to locate, measure, and choose the appropriate fasteners and how to do it effectively. And although you may be working with rough threads to assemble a generic piece and you may be working with fine threads to give accuracy into the project, the knowledge of such fundamentals will improve the outcomes of the project and prevent some common threading mistakes.

Have you had a bad experience with thread identification in your practice? Share your experience by leaving it in the comment box below, or by telling us what threading concerns you would prefer to learn more about. In order to recognize threads themselves, consider buying pretty thread gauges–they are self-promoting as invaluable commodities in terms of saving time and money in project delays, and of inappropriate fasteners.