Learn about vacuum forming – the cheap manufacturing of plastic. Get to know materials, applications, benefits, and how it is compared to other techniques in this extensive guide.

Introduction

Have you ever had a question about how the transparent plastic packaging of your electronics or the smooth dashboard parts of your automobile are manufactured? This usually can be answered with an interesting process known as vacuum forming. It is a quiet revolution in industries that has transformed industries over the decades, producing things as simple as food containers and as complex as aerospace parts with this versatile plastic shaping technique. Here, in this detailed guidebook, we are going to de-mystify the art of vacuum forming, the processes it entails, its uses, and why it may be the ideal manufacturing solution for your next project.

What Is Vacuum Forming?

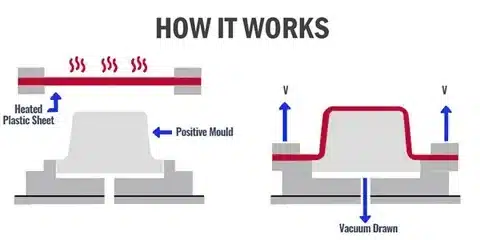

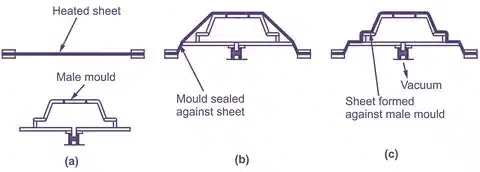

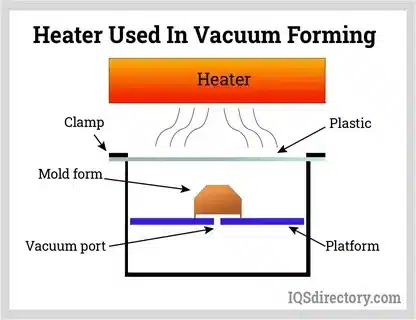

Vacuum forming is a more simplified form of thermo-forming in which a plastic sheet which is heated is pressed over a mold and then the sheet is molded down by vacuum pressure. These steps consist of a combination of important processes that ensure the ultimate production of accurate and long-lasting plastic components.

There are several steps to be followed in the vacuum forming process:

- Heating: A thermoplastic sheet is placed in a frame, and it is heated until it is pliable.

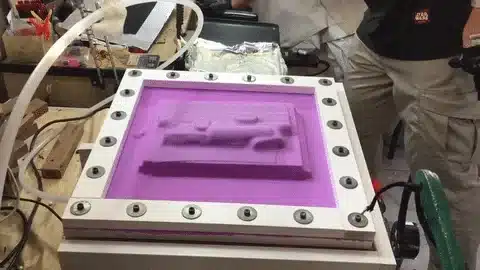

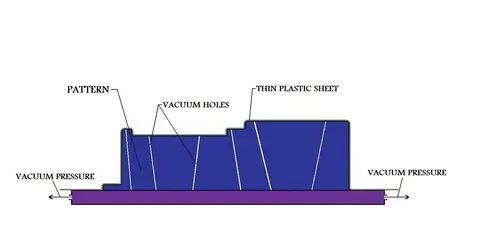

- Positioning: The hot sheet is moved onto a mold (usually of wood, aluminum, or composite) and pressed onto it.

- Vacuum Application: A vacuum is applied to the underside of the sheet, and this forces the plastic to cling firmly to the surface of the mold.

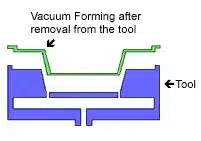

- Cooling: The plastic formed is allowed to cool and harden without the loss of shape of the mold.

- Trimming: that surplus is cut to form the end product.

Such simplicity also causes vacuum forming to be one of the most convenient and affordable ways of making plastic parts, including the prototyping and medium-volume production head start.

Materials Used in Vacuum Forming

Whether a vacuum forming project is successful is mainly determined by the choice of material. Several thermoplastics are especially good in this process:

Common Vacuum Forming Materials:

- ABS (Acrylonitrile Butadiene Styrene): Impact resistance and strength are good, and it can be used in automotive and electronics housing.

- PETG (Polyethylene Terephthalate Glycol): Crystal clear and has great chemical resistance, and is used in the packaging of medical and food products.

- HIPS (High Impact Polystyrene): This material is relatively inexpensive and forms well, typically used to package and label disposable items and signage.

- Polycarbonate: High strength and heat, as well as heat resistance, are compatible with safety devices and optics.

- Acrylic (PMMA): It has great clarity and can resist the weather, which is why it should be used in displays and architecture.

Material Selection Factors: Vacuum forming requires manufacturers to review numerous important factors when selecting materials, such as sheet thickness (0.5-6mm), which materials need to be flexible, surface finish needs, temperature resistance, chemical compatibility, and regulatory compliance based on the industry (medical or food service).

Advantages of Vacuum Forming

Vacuum forming has many advantages that predispose it as a favorable option for manufacturers in different fields:

Cost-Effectiveness: Low tooling costs of vacuum forming in comparison to injection molding are one of its greatest benefits. It can be prototyped and used in small to medium production runs, and is practical even when it comes to making moulds out of low-cost materials such as wood or aluminum. The lower initial investment enables businesses to experiment with designs and venture into markets with little financial risk.

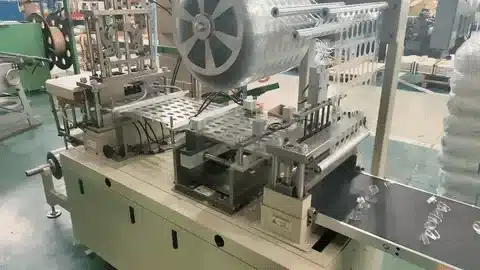

Speed and Efficiency: The Vacuum forming process provides very high turnaround times. When a mold is designed, it is possible to produce parts in minutes as opposed to hours. This quick manufacturing nature makes it ideal in the delivery of close deadlines and addressing the market needs with speed.

Design Flexibility: Engineers and designers value the capability of vacuum forming to respond to design changes easily and cost-effectively. Compared to injection molding tooling, which is also much more costly to modify, vacuum forming tooling can be readily modified to promote innovation and design refinements.

Lightweight Durability: Vacuum-formed components have a great strength-to-weight ratio and can be used in those products where weight reduction is vital, such as automotive components and aerospace applications. The homogeneity of the wall thickness that is attained by the appropriate forming methods guarantees uniform structural integrity.

Limitations of Vacuum Forming

As much as there are a lot of benefits associated with vacuum forming, one should be aware of its limitations:

Design Constraints: The process experiences difficulties with very deep draw and sharp angles. Multifaceted geometries with short radii or detailed features might not be able to form well because of material stretching constraints. Also, undercuts and internal features usually demand secondary operations and other manufacturing processes.

Material Limitations: Vacuum forming cannot be done in all thermoplastics. Material that has a small range of forming temperature or material that degrades during heating can be problematic. Deep-drawn parts may also exhibit variation in wall thickness, which may compromise structural integrity in sensitive applications.

Production Volume Considerations: Vacuum forming may not be the most cost-efficient solution to high-volume production because it does not scale down to very high volume production, where the tooling costs of injection molding can be recouped in millions of units.

Applications of Vacuum Forming

The flexibility of vacuum forming can be useful in many industries and applications:

Everyday Products: It is easy to see vacuum-formed products in everyday life without realizing it. This is used in common products like blister packaging of retail items, food packaging trays, point-of-purchase displays, storage, and architectural panels. The capability of the process to produce clear and protective packaging renders it inseparable from consumer goods.

Industry-Specific Applications: Vacuum forming has special capabilities used in various industries. It manufactures interior trim panels, dashboards, and protective covers in the car industry. In medicine, it is used in equipment housing, components of diagnostic devices, and sterile packaging. Vacuum forming is used by the aerospace industry to make lightweight interior parts and shields. It is used by electronics manufacturers to package their devices, provide protection cases, and their components.

Emerging Applications: With the maturation of technology, new applications are being added. Vacuum forming is used in custom orthotics and prosthetics, architectural facades, exhibition displays, and even in art installations, where it is important to have both precision and cost-effectiveness with flexibility in design.

Vacuum Forming vs. Other Manufacturing Methods

In production, it is better to know how vacuum forming is compared to other processes of manufacturing to make informed choices:

Vacuum Forming vs. Injection Molding: Injection molding is best suited to large quantities of production with complicated shapes and very fine tolerances, and involves a large initial investment in tools. Vacuum forming is less costly in terms of tooling and has shorter set-up time, yet it has restrictions in design and characteristically heavier cross-sections. Vacuum forming can make more economic sense when producing short production runs of less than 10,000 parts.

Vacuum Forming vs. Pressure Forming: Pressure forming, the more advanced form of vacuum forming, entails the application of both vacuum and pressure to obtain more details and sharper edges. Although pressure forming is used to achieve superior surface finishes, it needs more costly equipment and tooling.

Decision Guide: Select vacuum forming when you require cost-effective prototyping, moderate volume of production, or a lightweight component, or when design flexibility is a major concern. Think injection where volume is large and geometries are complex, and think pressure when high-quality surfaces are worth the extra expense.

Conclusion

One of the most popular and flexible processes of shaping plastic in the manufacturing industry is vacuum forming, which offers ideal cost-efficiency, time-saving, and design options. This excellent process keeps on driving innovativeness in countless industries, including the common products we consume and the specialized industrial products which are specialized. The use of vacuum forming should be seriously considered, whether you are prototyping, launching new products, or seeking a cost-effective method of manufacturing, as it may be able to provide low tooling costs, low turnaround times, and flexibility with materials. As the needs of the manufacturing process shift to a more customized and quicker need-to-deliver in lead times, the vacuum forming intrinsically endowed benefits put it in the hands of even an increasingly vital component of the arsenal of the modern manufacturer, and provide the combination of efficiency, cost-saving, and engineering ability that your next project rightly merits.