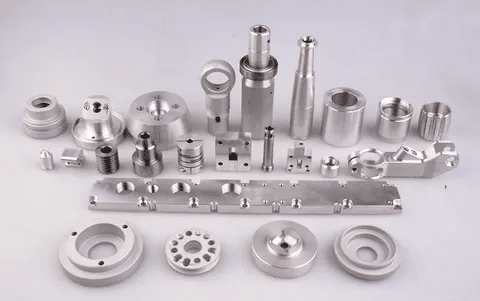

CNC Machine Parts: Complete Guide to Components and Functions

CNC (Computer Numerical Control) machines are the pinnacle of the modern precision manufacturing business which is made up of the

CNC (Computer Numerical Control) machines are the pinnacle of the modern precision manufacturing business which is made up of the

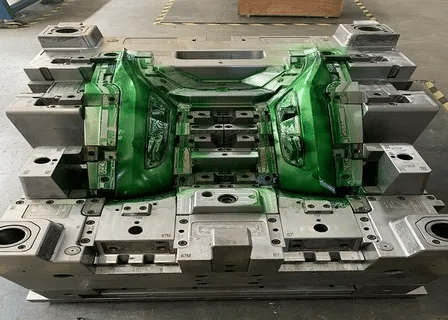

The injection molding tolerance is a very important specification applicable in achieving tolerance and accuracy of dimensions of fabricated items.

CNC machining tolerances CNC machining tolerances specify acceptable variation between parts produced and are key towards proper fit, function and

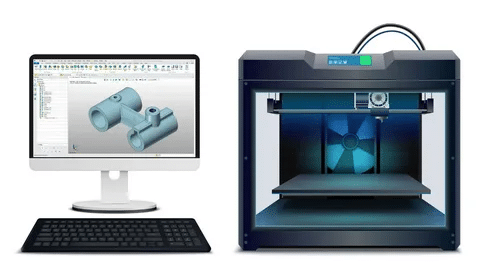

Knowledge of the 3D printer file formats is essential in the successful additive manufacturing project. This is a full tutorial

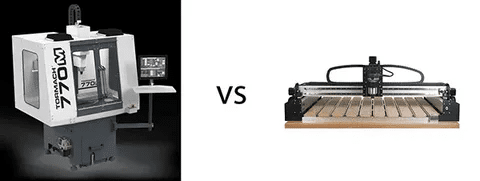

CNC milling machines and routers have distinct needs of manufacturing where milling machines have an added advantage of precision (tolerance

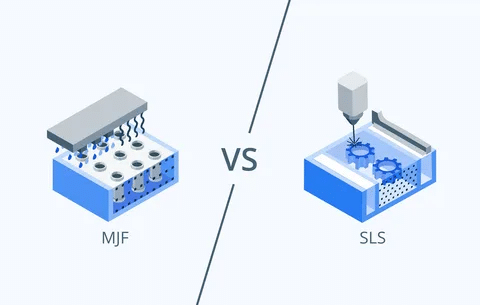

MJF (Multi Jet Fusion) and SLS (Selective Laser Sintering) are two 3D printing processes that are typically used for creating

FDM (Fused Deposition Modeling) and SLA (Stereolithography) are two of the most common 3D printing technologies, each designed for a

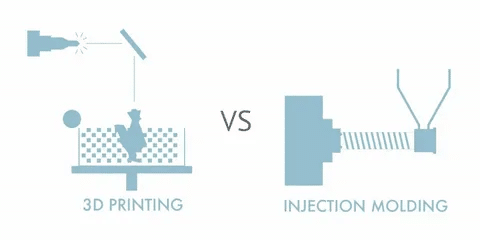

Selecting between injection molding and 3D printing is your project’s requirement for volume, cost, speed, and complexity. 3D printing works

The material removal rate (MRR) refers to the quantity of material eliminated in one minute of machining as it is

Metal forging industry is a seamless combination of traditional artisan and more modern technology as these metalwork shops create essential

Ze Cheng Precision Mold Co., Ltd. uses modern Japanese equipment and rigorous quality control to produce high-precision mold parts and machine components to international standards, exporting worldwide.

WhatsApp us