PET vs PETG: The Complete Guide to Choosing the Right Plastic

PET and PETG are closely related plastics with unique properties that make them suitable for different applications. PET (polyethylene terephthalate)

PET and PETG are closely related plastics with unique properties that make them suitable for different applications. PET (polyethylene terephthalate)

PET plastic, or polyethylene terephthalate, is a strong, lightweight, and highly versatile polymer widely used in packaging and consumer products.

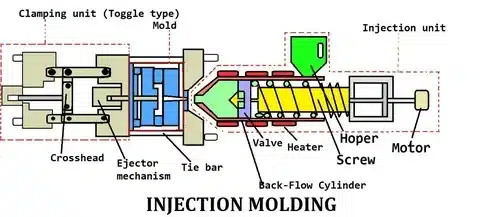

Modern injection molding technologies cover an extensive array of specialized processes, such as gas-assisted molding to achieve material efficiency, thin-wall

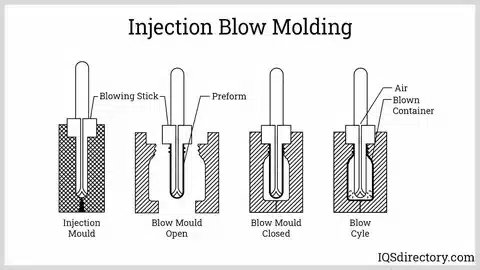

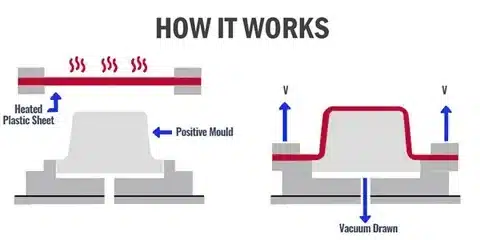

Blow molding and injection molding are two widely used plastic manufacturing processes, each suited for different project needs. Blow molding

Blow-molded plastic is one of the pillars of contemporary manufacturing and is a form of manufacturing that involves three main

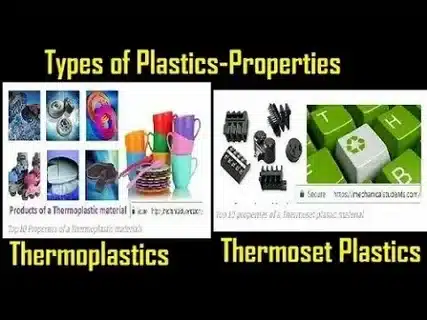

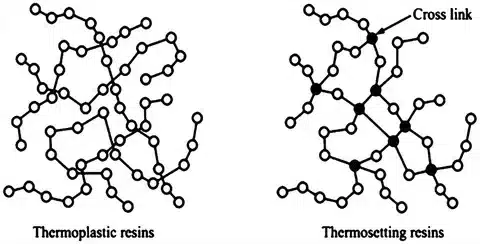

Thermoplastics and thermosetting plastics are two primary categories of polymers, each with distinct characteristics and applications. Thermoplastics are materials that

The article What is a Thermoplastic: Things You Need To Know explains the unique characteristics, advantages, and applications of thermoplastic

The article How Plastic is Formed: A Complete Guide to Manufacturing outlines the entire process of turning raw materials into

Thermoplastics are very versatile types of polymer that can be re-heated and re-shaped, and, consequently, are the most fitting polymers

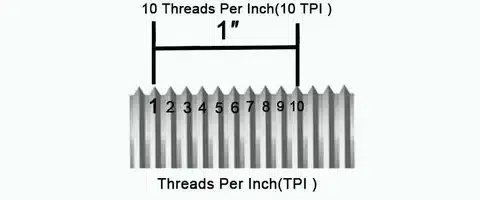

Threads per inch (TPI) and thread pitch are two distinct measures of threaded fasteners–TPI is a thread count per inch

Ze Cheng Precision Mold Co., Ltd. uses modern Japanese equipment and rigorous quality control to produce high-precision mold parts and machine components to international standards, exporting worldwide.

WhatsApp us