This article considers Computer Numerical Control (CNC) system as an innovation that defines the modern age of manufacture in the cnc machining industry . With CNC technology, along with cnc milling machines, milling tools, bits and pieces ranging from airplane parts to common household items can be mass produced at rates that are incredibly fast, are duplicate, and have fine tolerances. However CNC has become part of the norm in the modern employ of materials and fabrication, the working principles of it are rarely well understood by people who are not into engineering. In the next section, I am going to elaborate on each of these questions and explain how exactly CNC works, particularly focusing on cnc programming . It is now time to get into the nitty-gritty and explore the digital core of this awesome technological accomplishment.

The Fundamentals of CNC Technology

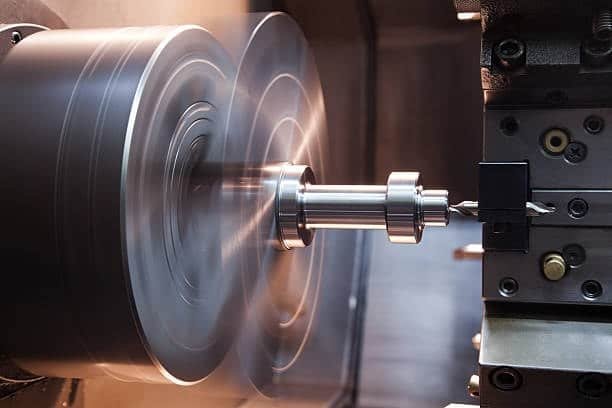

CNC stands for computer numerically controlled technologies and it can be described as the automation of process of Using tools like cnc machines, cnc machine tools, lathes, mills, routers or grinders and else and it is driven or controlled by a computer program that includes various types of cnc machines . Unlike manually operated systems, the operations of CNC systems are carried out by means of codes that have been input into the system through cnc programs and cam software and cam software . to control movements of a tool or any given component. These are written in a language that is called G-code to control the location, feed rate, depth, and sequence of the tool to accomplish the operations flawlessly.

From Digital Design to Physical Reality:

One of the greatest aspects of CNC is the fact that it can take a digital world and physically manifest it. A product or a component starts with just a cad model or CAD (Computer-Aided design) file, which is the basis of the cnc machining process as a subtractive manufacturing process . Configuring the tool paths and cutting conditions to produce this design is then done on a CAM (Computer-Aided Manufacturing) program. From there the machine acquires the code and completes the task of drilling, milling, cutting or shaping a material through various machining operations and processes with little contribution from the operator.

Core Components of a CNC Routers

A functional CNC routers system can be said to comprise of different types of cnc machines including cnc lathes and sub-systems of complex machinery singly or in coordination with the other sub-systems.

- Controller Unit: Known as the heart of the CNC Machine, the controller has a responsibility of decoding the G-code and conveying electrical signals that control the operation of actuators and motors.

- Drive System: Stepper or servo motors are used to drive the various parts of the machine along the given axes as X, Y, Z etc. They are motors which are driven by signals from the controller—the way they move and synchronize is consequent of the controller.

- Machine Tool: This can be a cutting tool, drill, or end mill, depending on the application that it is being used for. The movements of the tool are very synchronized for the specific task to be executed on the workpiece.

- Feedback Mechanisms: Most of the CNC systems have sensors or encoders that send back information to the controller to regulate position and check for any deviation during operation.

- User Interface: Operators feed in data and parameters and control or modify process via graphical displays or computer interfaces.

The CNC Machining Process: From Code to Component

After the digital design of the required object is done and the tool paths to be followed by the cnc machining equipment rotating cutting tool in the cnc machining process are programmed, the machining process starts. Here’s how the cnc process unfolds step-by-step:

- Preparation: The blank, which is the metal that has been prepared, is firmly held between the machine base or in a holder. The correct tool for proper is also established in the spindle.

- Code Execution: It means that the machine controller scans the G-code line by line and then performs the necessary operations based on it. This means that each command prescribes a particular operation i.e. movement to a certain coordinate, tool change or change of spindle speed.

- Movement and Cutting: The tool of the machine is navigated with motors and encoders along the X, Y and Z axes. From the general contour, the material is carved until it assumes the desired form in what is referred to or known as subtractive process.

- Finishing and Quality Check: Sub-processes, such as polishing or déburring, for example, may then take place. Afterward, the finished component is checked for tolarence and functionality.

Applications of CNC in Industry manufacturing process

CNC milling in fact is widely used in various industries due to its flexibility. In aerospace in particular, cnc machinery out turnings manufacture turbine blades, wing ribs, and structural brackets; parts that require a high degree of accuracy and use lightweight materials. In automotive industry of industry, CNC milling is used in the manufacture of engine blocks, transaxle housings, and cnc lathes milling operations , cnc turning, as well as various other channeling molds.

Expanding Beyond Manufacturing

This is because the electronics industry makes use of CNC milling in manufacturing PCB prototypes, micro-components, and connectors. Today even in woodworking and jewellery making industries, the cnc machining work and cnc operators utilize cnc drilling machines, which cnc machining makes possible and machining industry which is significant. use cnc routers, cnc drilling, computers controlled router and engraving machines for customized logos, designs and shapes which are faster and more accurate than handwork.

Benefits of CNC Milling Machining

The benefits of adopting the CNC technology are as significant and diverse. First and foremost is precision, particularly precision cnc machining . Most CNC machines, including cnc turning, can maintain tolerances that in some cases are even in the thousandth of a millimeter range, thus imparting uniformity at the same time as scalability. Secondly, repeatability makes it possible to produce the same part using advanced machining tools a thousand or more times with absolutely no variations in size and quality, something that would be harder to achieve machining operations, and if it is, time-consuming to achieve by hand.

Speed is another significant advantage. CNC milling saves what used to take hours when done manually, to as little as a few minutes, streamlining the entire manufacturing process . Also, there is less reliance on manpower due to pre programmed computer software , less chance of human mistakes, and improved safety in the cnc manufacturing process and injection molding techniques as well. Versatility in programming and computer aided manufacturing cam lso enables shops to change from one project to the other with ease hence making CNC machines, along with laser cutting capabilities, ideal for use in both large-scale production as well as small-scale production or even the creation of prototypes.

Limitations and Challenges of CNC lathes machining work

It also important to note that CNC has its shortcomings. A possible disadvantage is a high initial cost that is required for purchasing machines, software, manufacturing process and training of workers for manual machining . Furthermore, the level of accuracy of the cnc controller program and the specific g code or miscellaneous machine codes used in the last step significantly determines the quality of the final machine parts output. The G-code file that is poorly written can lead to breakage of cad model tools or must produce tools which are defective.

It also has some drawbacks, for example, there is a danger in depending too much in automation. Despite the advancement in technology, some of the roles remain to be setting up of machines and understanding manual lathes and types of cnc machine functions , including the role of a cnc machinist, conduct cnc lathes and conducting cnc machining operations. translating of prints, solving of errors, & quality assurance requiring skilled machinists. Thus, we can see that the cnc industry technology is not a threat to the job, but rather beneficial in that it increases the demand for expertise.

Conclusion

CNC machinist is amongst the great inventions that have contributed significantly to how people work on developing technologies in the manufacturing industry and ways of improving on the materials that exist in the modern world today. It has a unique feature of taking a computer aided design cad model virtual design and turning it into reality in the cnc manufacturing process and engineering perfection and has not only set new benchmarks but also paved ways for novel techniques, including the use of electric discharge types of cnc machines and milling machine parts . in design and production, versatility in manufacturing the revolutionised the concept of mechanic tools. There are still some limitations that could be seen today, but the further development of the CNC plasma cutters is expected to provide even higher accuracy, advanced control, and easier access in the future. CNC is not just a tool but a pathway to the smart manufacturing system of the fabrication process for the fourth industrial revolution.